Boring and reaming combined machine

A combination machine and machine tool technology, which is applied in the direction of metal processing machinery parts, clamping, support, etc., can solve the problems of low processing efficiency and achieve the effects of high processing efficiency, precise reaming, and convenient cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The following is attached Figure 1-10 The application is described in further detail.

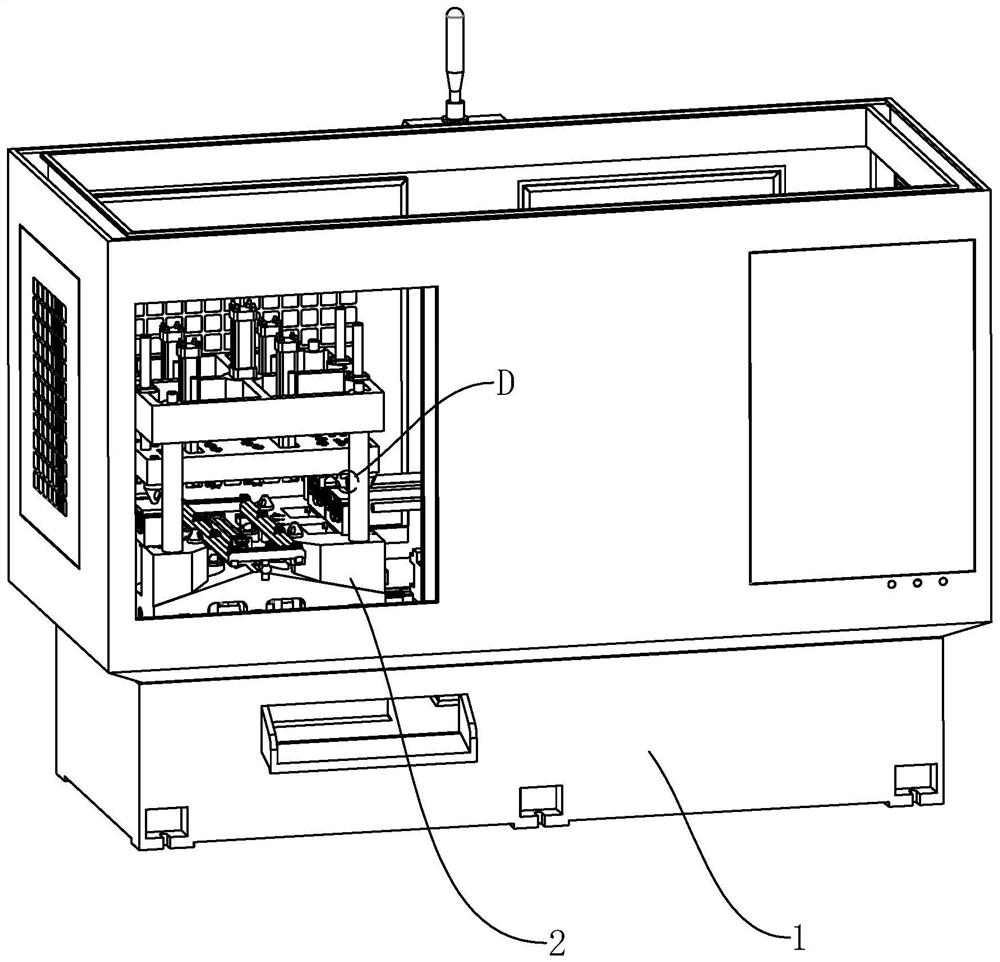

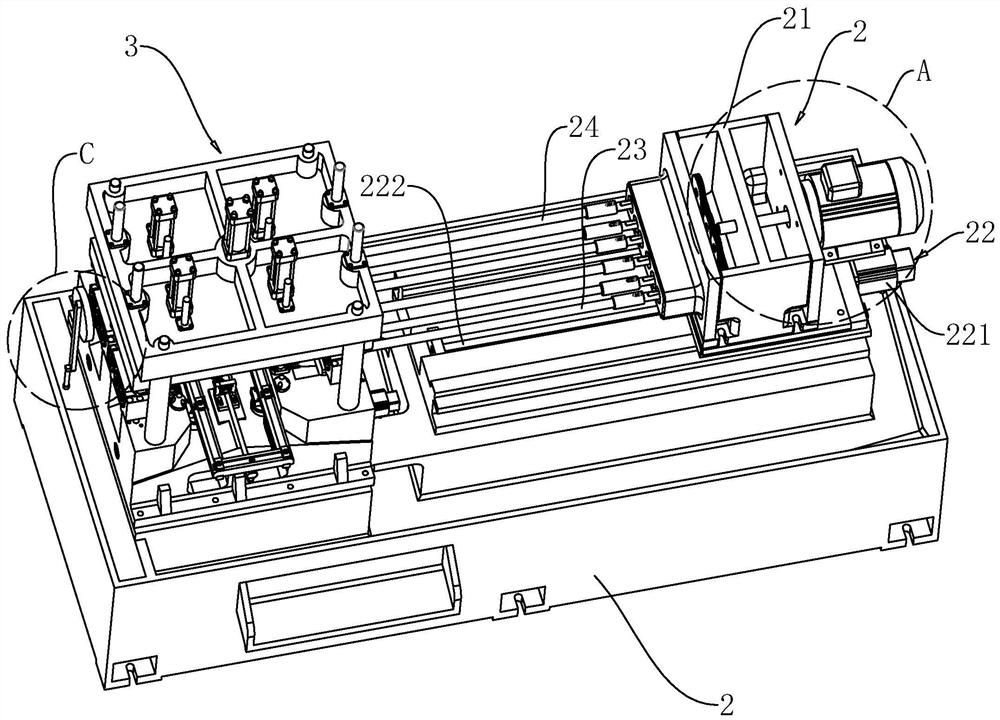

[0047] The embodiment of the present application discloses a boring-hinge combination machine. refer to figure 1 , figure 2 The boring-hinge combination machine of this embodiment includes a machine tool 1, a processing mechanism 2 slidingly arranged on the machine tool 1, a fixing mechanism 3 arranged on the machine tool 1 for fixing workpieces, and the sliding direction of the processing mechanism 2 is away from or close to the fixed Mechanism 3, and processing mechanism 2 are used to bore and ream the workpiece.

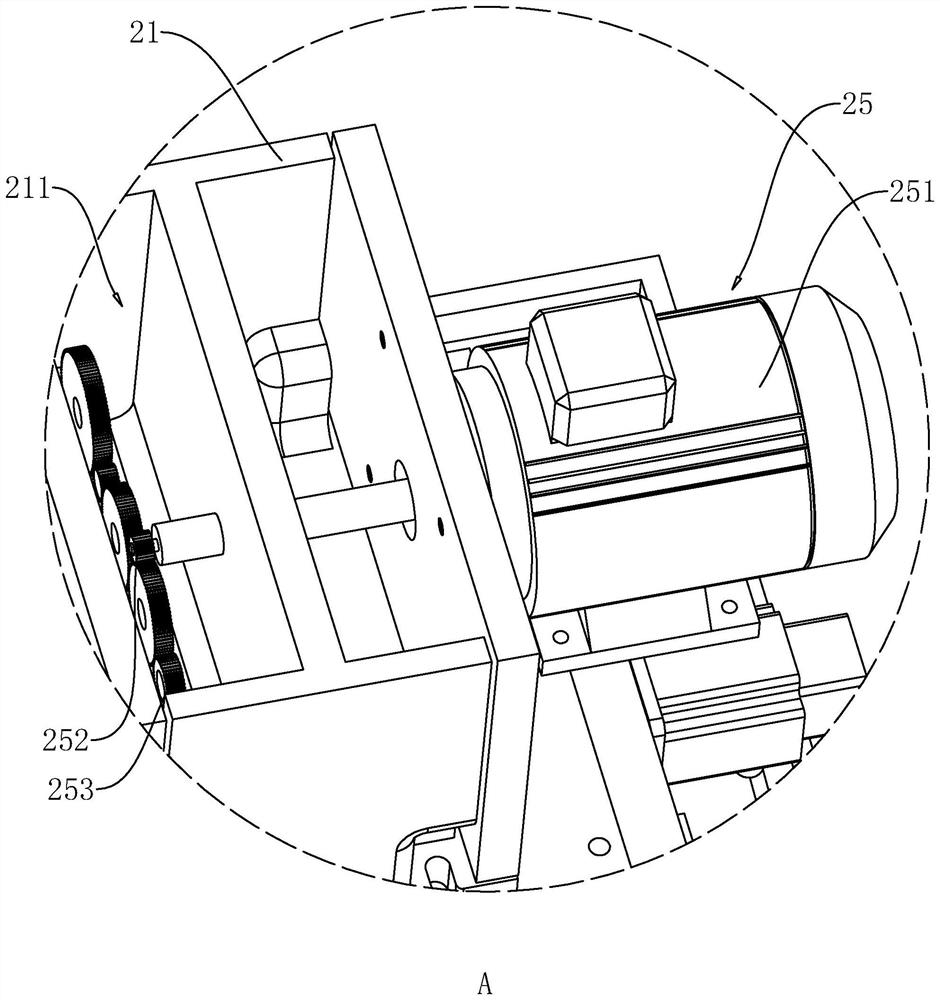

[0048] refer to figure 2 , the processing mechanism 2 includes a base 21 and a sliding assembly 22 that drives the base 21 to slide on the machine tool 1 . Sliding assembly 22 comprises sliding motor 221 and sliding screw mandrel 222, and sliding motor 221 is fixed on the machine tool 1, and the motor shaft of sliding motor 221 is towards fixed mechanism 3, and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com