Preparation process of aerated concrete block

A technology of aerated concrete and preparation process, which is applied to ceramic products, other household appliances, household appliances, etc., and can solve problems such as uneven air hole size and large strength deviation of aerated concrete blocks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

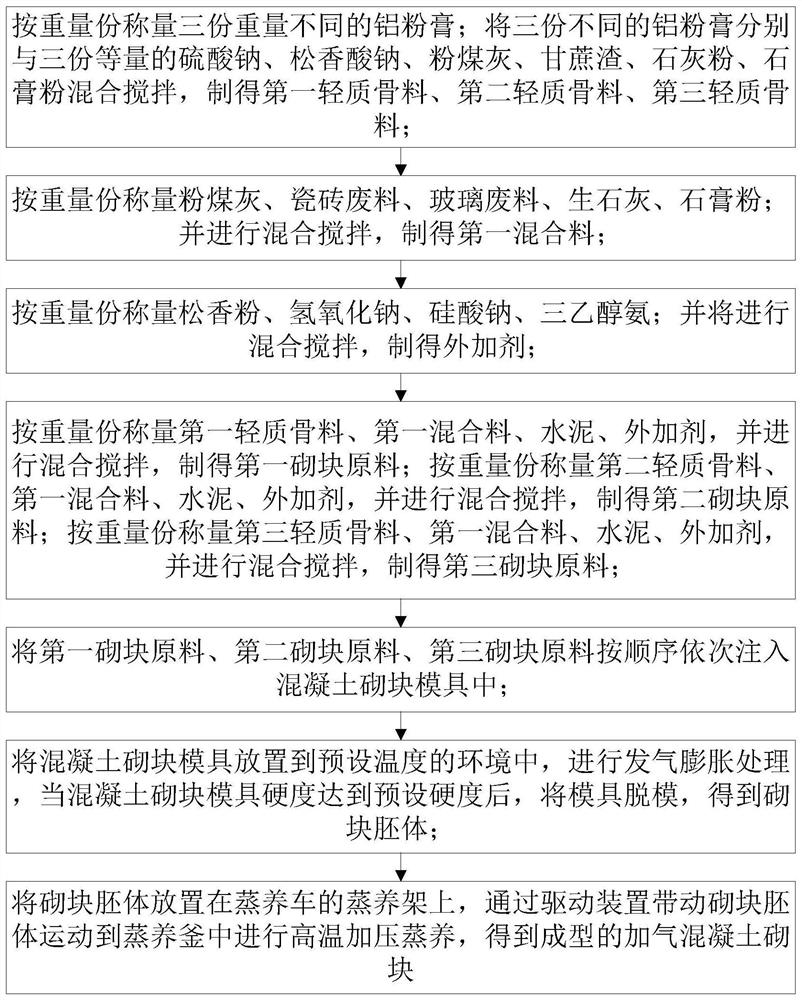

[0027] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

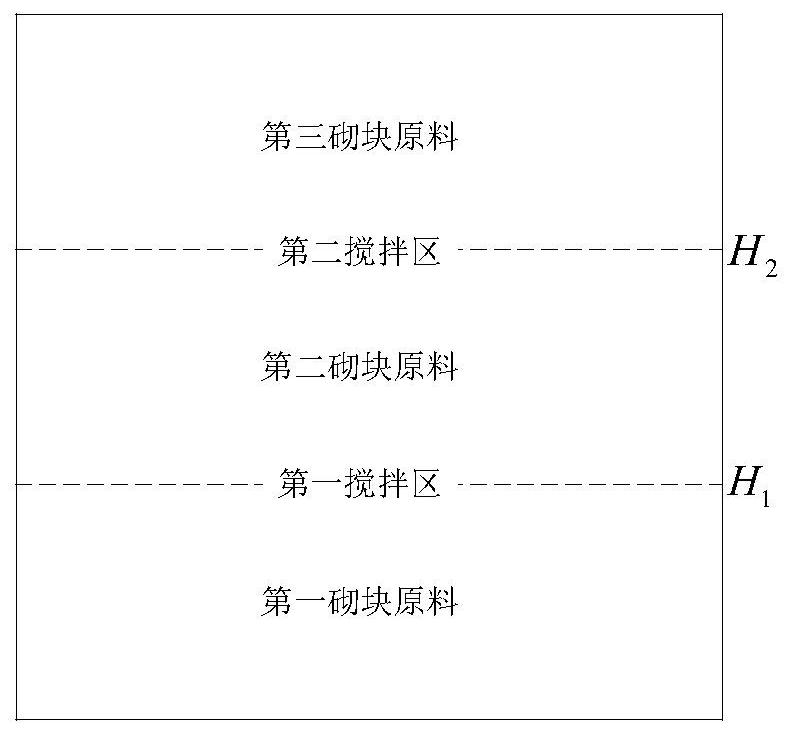

[0028] Such as Figure 1-2 As shown, in a specific embodiment of the present invention, a kind of preparation technology of air-entrained concrete block is provided, and described technology comprises the following steps:

[0029]Step S1, weighing three parts by weight of different aluminum powder pastes, and weighing three parts by weight of sodium sulfate, sodium rosinate, fly ash, bagasse, lime powder, and gypsum powder; Three parts of different aluminum powder pastes are mixed with three equal parts of the sodium sulfate, the sodium abietate, the fly ash, the bagasse, the lime powder, and the gypsum powder respectively, Prepare the first lightweight aggregate, the second lightweight aggregate, and the third lightweight aggregate; wherein, the first lightweight aggregate, the second lightweight aggregate, and the third lightweight aggregate The relations...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com