Stone crushing device for mining

A crushing and mining technology, which is applied in the field of crushing devices for mining, can solve the problems of incomplete crushing, difficult dust and debris, and easy accumulation of ore, so as to achieve the effect of prolonging the service life and good crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

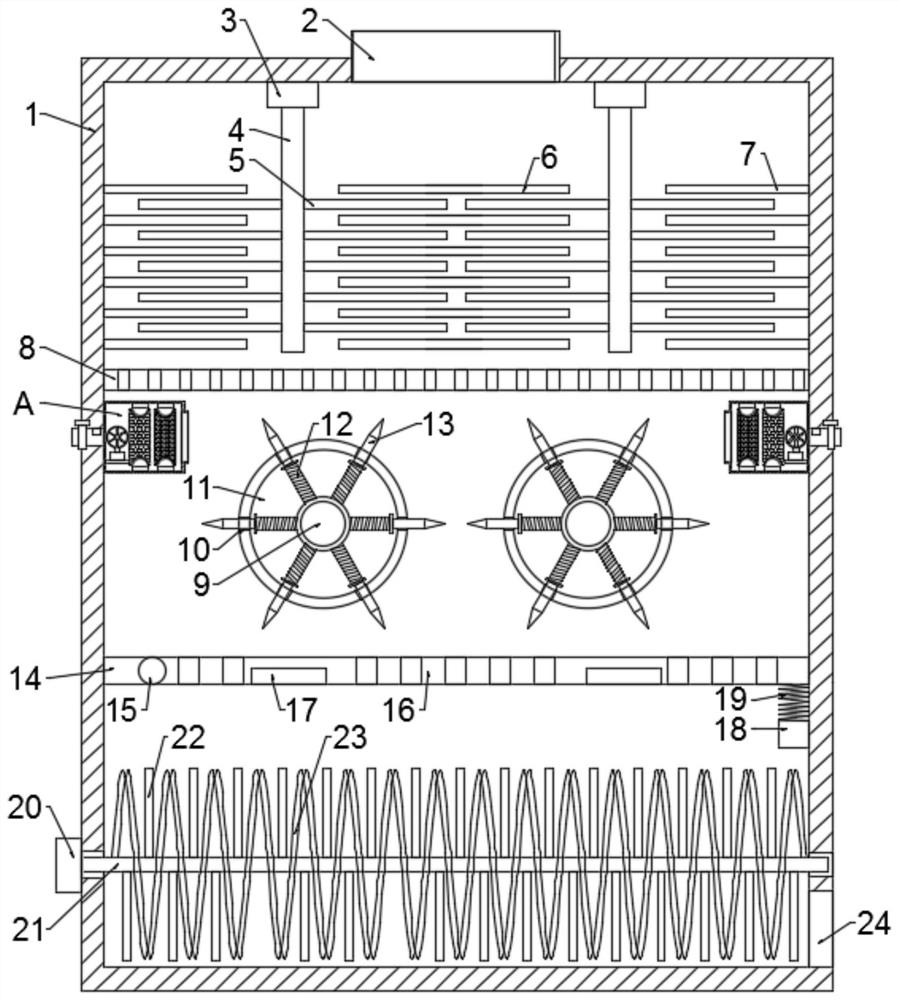

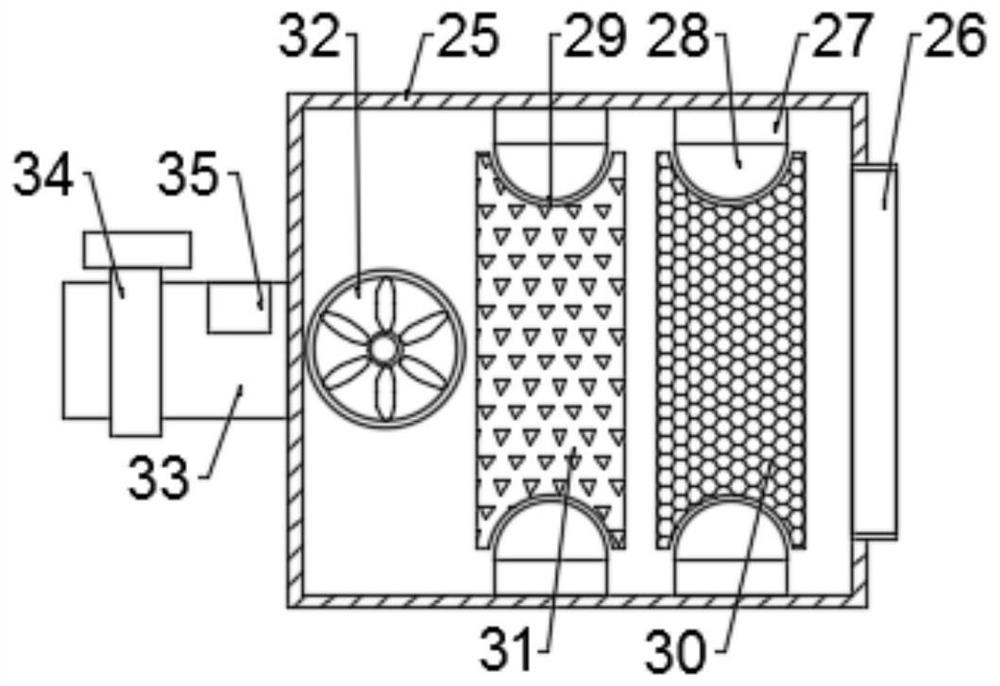

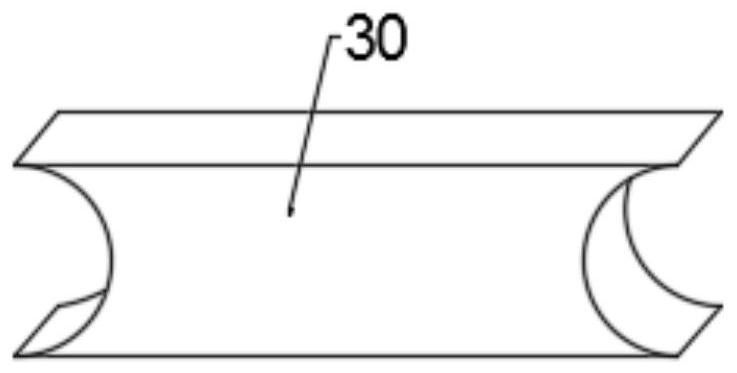

[0030] see Figure 1 ~ Figure 3, a mining crushing device, comprising a device box 1, the center of the device box 1 is provided with a feed port 2, the feed port 2 runs through the device box 1, and the inside of the device box 1 A first rotating electrical machine 3 is symmetrically arranged, and the first rotating electrical machine 3 is fixedly connected to the device box 1, and the output end of the device box 1 is fixedly connected to the first rotating shaft 4, and the first rotating shaft 4 is symmetrically arranged with Several rotary blades 5, the rotary blades 5 are fixedly connected to the first rotary shaft 4, the first sieve plate 8 is arranged in the device box 1, the first sieve plate 8 is arranged below the rotary blades 5, the The left side of the device box 1 is provided with a second rotating motor 20, the output end of the second rotating motor 20 is fixedly connected to the second rotating shaft 21, the second rotating shaft 21 runs through the device cas...

Embodiment 2

[0038] see Figure 1 to Figure 5 , a rock crushing device for mining, including a device box 1, and also includes a third rotating motor 36, a turbine 37, a weighing device 38, a gear 39, a receiving plate 40 and a rack 41, and the center of the device box 1 is The position is provided with a feed port 2, the feed port 2 runs through the device box 1, and the first rotating motor 3 is symmetrically arranged in the device box 1, and the first rotating motor 3 is fixedly connected to the device box 1, The output end of the device box 1 is fixedly connected to the first rotating shaft 4, and several rotating blades 5 are symmetrically arranged on the first rotating shaft 4, and the rotating blades 5 are fixedly connected to the first rotating shaft 4, and the device box A first sieve plate 8 is arranged inside the body 1, and the first sieve plate 8 is arranged below the rotary blade 5, and a second rotating motor 20 is arranged on the left side of the device box 1, and the outpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com