Multi-station collaborative pouring system and pouring method

A technology of pouring system and pouring method, which is applied in the field of iron and steel industry, can solve the problems of uncontrollable pouring time and low pouring efficiency rate, and achieve the effect of improving pouring work efficiency, improving pouring efficiency, and increasing pouring rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

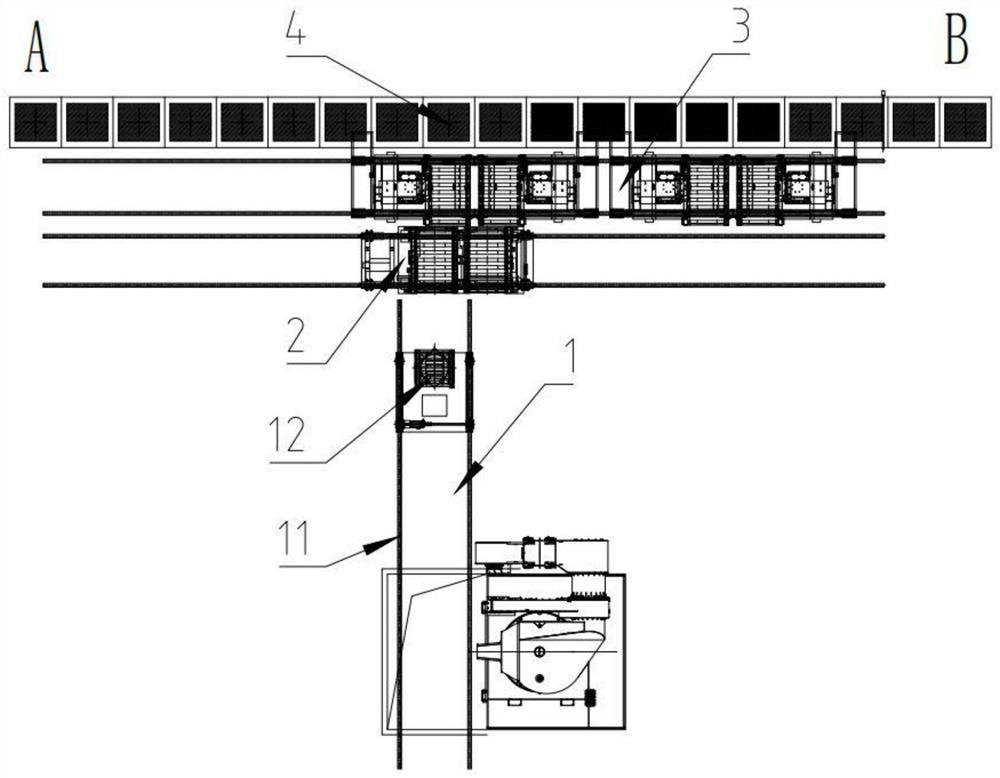

[0047] This embodiment provides a multi-station cooperative pouring system, see figure 1 , including a transfer module 1, a coordination module 2, a pouring module 3 and a molding module 4. In this embodiment, the molten metal used for pouring is molten iron, and the molten iron is picked up from the electric furnace by the transfer module 1 and transferred to the coordination module 2, The cooperative module 2 then transfers the molten iron to the pouring module 3, and the pouring module 3 is driven to complete the pouring work on the molding module 4, realizing automatic pouring of the production line and effectively increasing the pouring rate.

[0048] In this embodiment, the transfer module 1 includes a transfer track 11 on which a tilting transfer vehicle 12 moving along the transfer track 11 is arranged. For the specific structure of the transfer system, refer to the Chinese patent CN202010263596.X previously applied by the inventor. I won't go into details here.

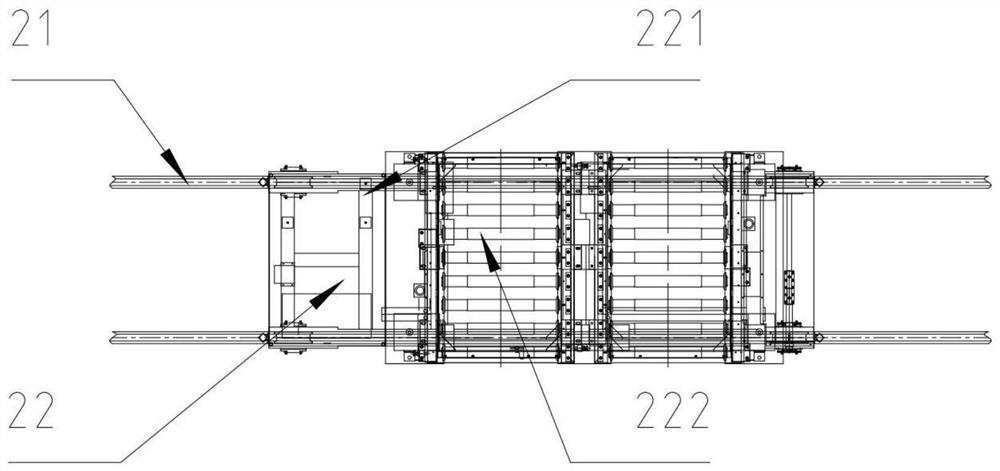

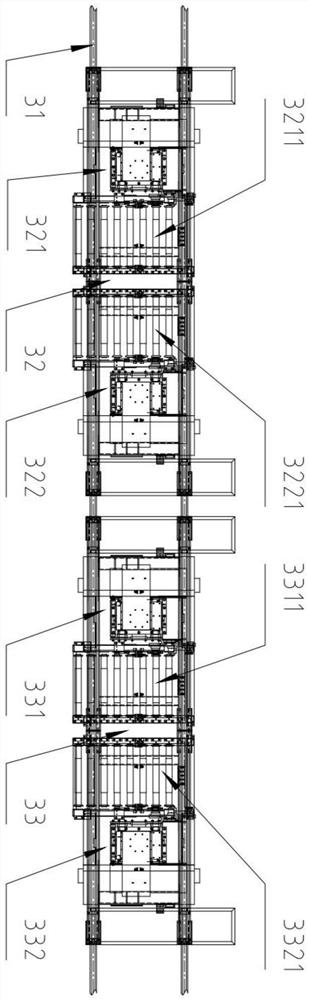

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com