Electric hydraulic excavator special for tunnel

A technology for hydraulic excavators and excavators, which is applied to mechanically driven excavators/dredgers, etc., can solve the problems of large turning radius of the manipulator, and achieve the effects of reducing energy consumption, reducing the amount of expansion and contraction, and reducing carbon emissions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

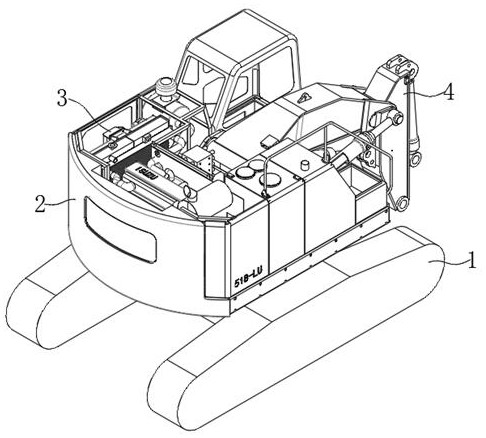

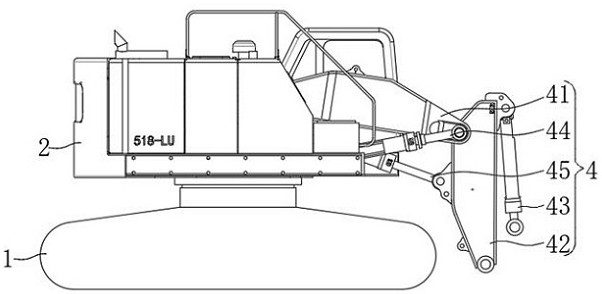

[0039] Please refer to figure 1 , figure 2 ,in, figure 1 A schematic structural view of the first embodiment of the tunnel-specific electro-hydraulic excavator provided by the present invention; figure 2 It is a schematic diagram of the side structure of the electro-hydraulic excavator dedicated to tunnels provided by the present invention. Electro-hydraulic excavators for tunnels, including:

[0040] The walking X-frame assembly 1 for moving on the ground, the upper frame assembly 2 as the external main structure of the excavator, the power output assembly 3 for providing power support for the excavator, and the power output assembly 3 for installing and driving the excavator The mechanical arm assembly 4 for workpiece movement;

[0041] The mechanical arm assembly 4 includes a first support arm 41, the first support arm 41 rotates on the upper frame assembly 2, and the maximum rotation height of the first support arm 41 is less than or equal to the upper frame assembly...

no. 2 example

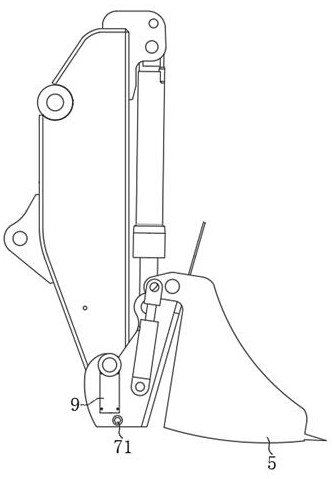

[0055] Please refer to image 3 , Figure 4 and Figure 5 , based on the first embodiment of the present invention is an electro-hydraulic excavator dedicated to tunnels, the second embodiment of the present invention provides another electro-hydraulic excavator dedicated to tunnels, wherein the second embodiment does not hinder the first embodiment independent implementation of technical solutions.

[0056] Specifically, the present invention provides another electro-hydraulic excavator dedicated to tunnels, which differs in that:

[0057] An excavation bucket 5 is installed on the bottom of the second support arm 42, and both sides of the exterior of the excavation bucket 5 are provided with movable grooves 6, and the outer side of the movable groove 6 extends to the inner side of the excavation bucket 5. Pass through the active slot 6 so that the external connecting piece connects the top of the excavating bucket 5 with the second support arm 42 .

[0058] The two movab...

no. 3 example

[0067] Please refer to Figure 5 , based on the first embodiment of the present invention is an electro-hydraulic excavator dedicated to tunnels, the third embodiment of the present invention provides another electro-hydraulic excavator dedicated to tunnels, wherein the third embodiment does not hinder the first embodiment independent implementation of technical solutions.

[0068] Specifically, the present invention provides another electro-hydraulic excavator dedicated to tunnels, which differs in that:

[0069] The top of the locking block 73 is provided with a buffer structure 8, the buffer structure 8 includes a movable block 81, the movable block 81 slides on the top of the locking block 73, and the left and right sides of the movable block 81 are Both sides are fixedly equipped with a connecting rod 82, the outside of the connecting rod 82 is sleeved with an elastic member 83, the outside of the connecting rod 82 is slidably connected with the inside of the locking blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com