Column foot bifurcated type combination column with reduced anchoring depth

A technology of combining columns and column bases, applied in the directions of columns, piers, pillars, etc., can solve the problems of increased equipment costs, labor costs, large excavation depths of foundation pits, and increased construction periods, so as to enhance the embedded effect and reduce comprehensive Cost and effect of reducing excavation depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the purpose, technical solution and advantages of the present invention clearer, the technical solution of the present invention will be further described below.

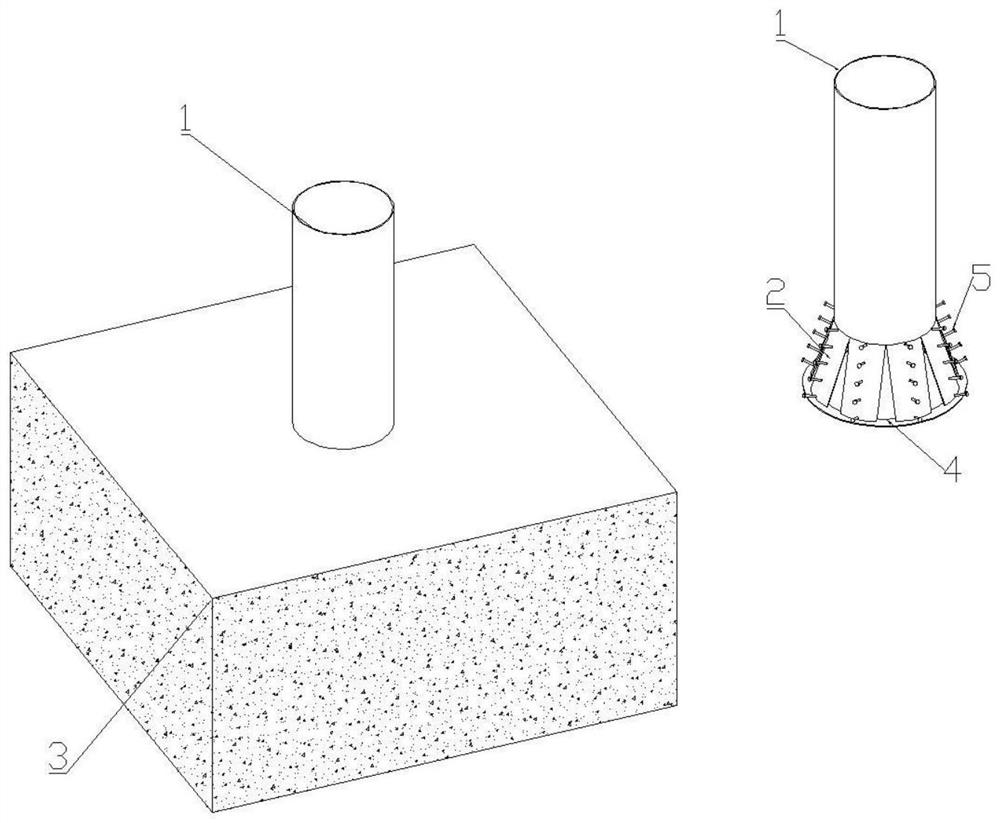

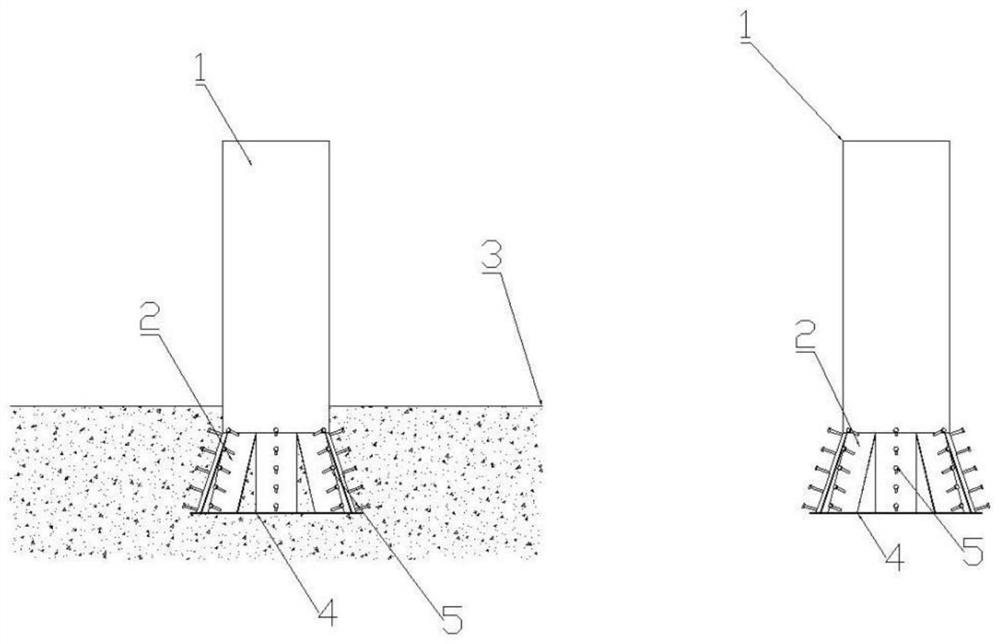

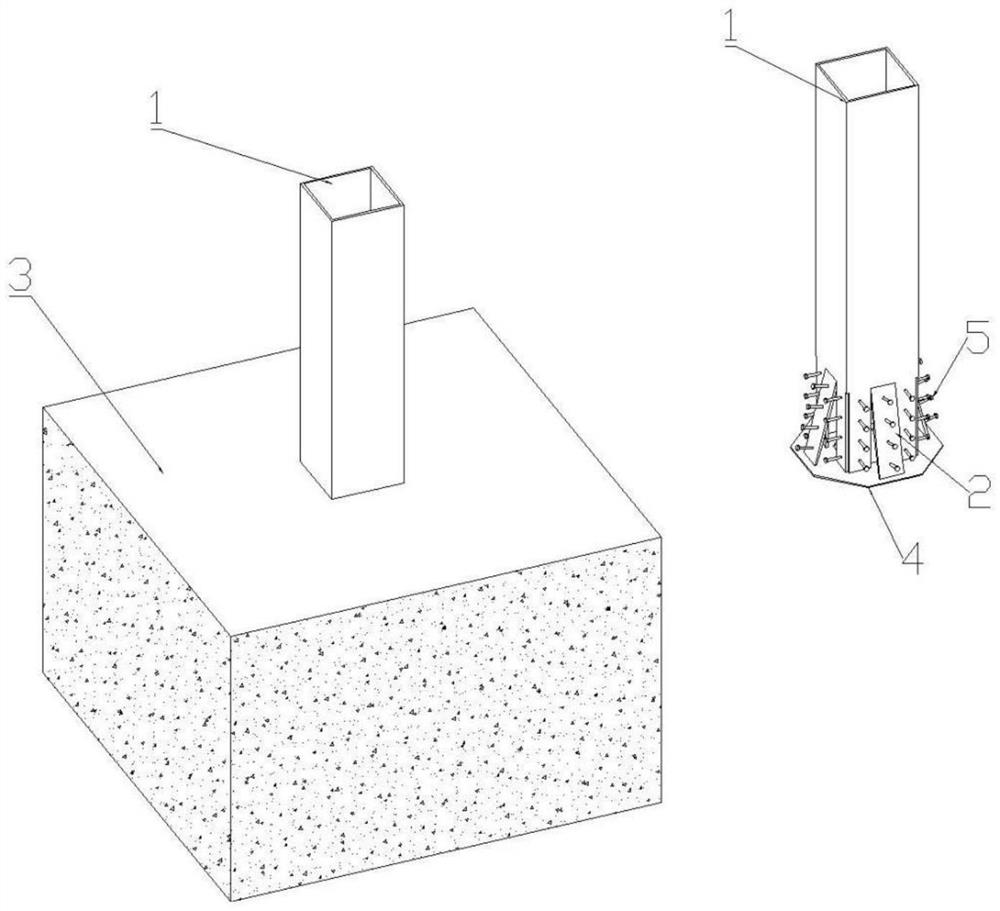

[0020] The present invention proposes a combination column with split foot for reducing the anchorage depth. The combined column is a split foot combination column 1; the column foot of the combined column 1 is cut upward from the bottom of the column foot to cut out multiple pieces of anchorage. Plate 2; the bottom of each anchor plate 2 is bifurcated towards the outside of the column, forming a scattered tree root structure; the gap generated by the bifurcation of the anchor plate 2 is used to connect the concrete inside the tube and the concrete outside the tube of the combined column 1; bifurcated The reinforced version does not increase the steel consumption of the original composite column 1, and the overall steel cost does not increase, but it is similar to the structure of the tree roo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com