Disassembly-free tray buckle foot hand stand bench formwork and construction method of disassembly-free tray buckle foot hand stand bench formwork

A hand frame and buckle technology, which is applied to formwork/template/work frame, on-site preparation of building components, construction, etc., can solve the problems of prolonged construction period, low construction efficiency, high cost, and achieve stable structural bearing capacity. High, saving manpower and material costs, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

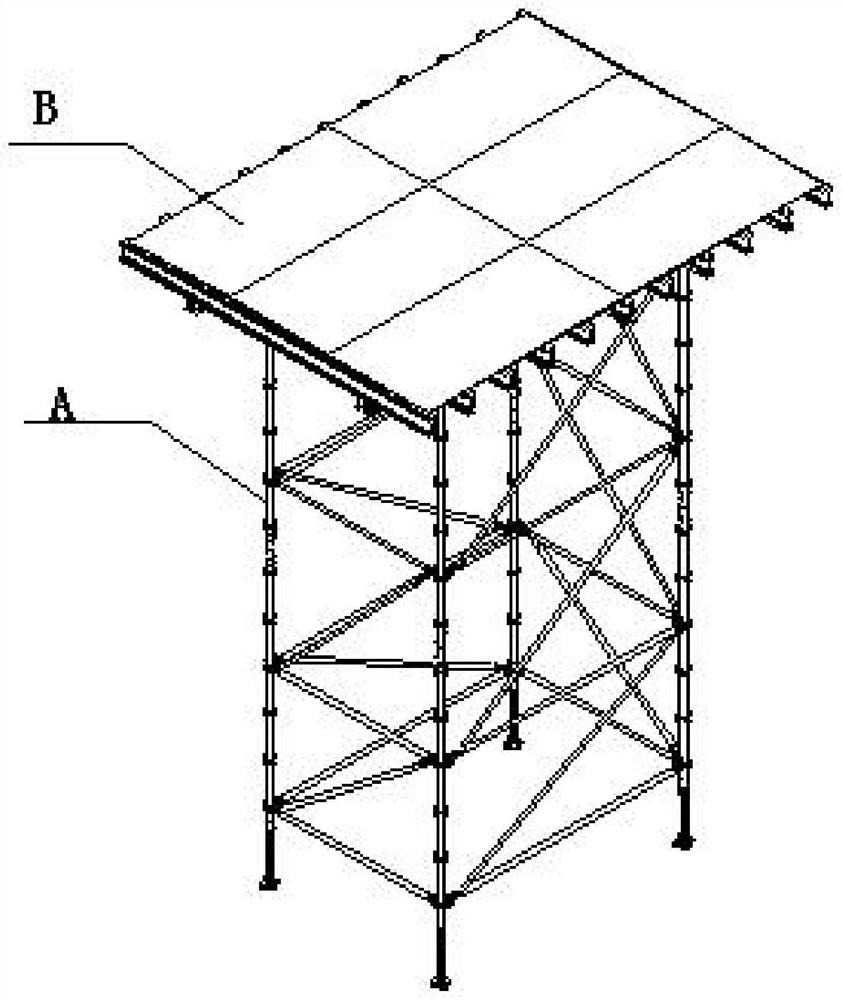

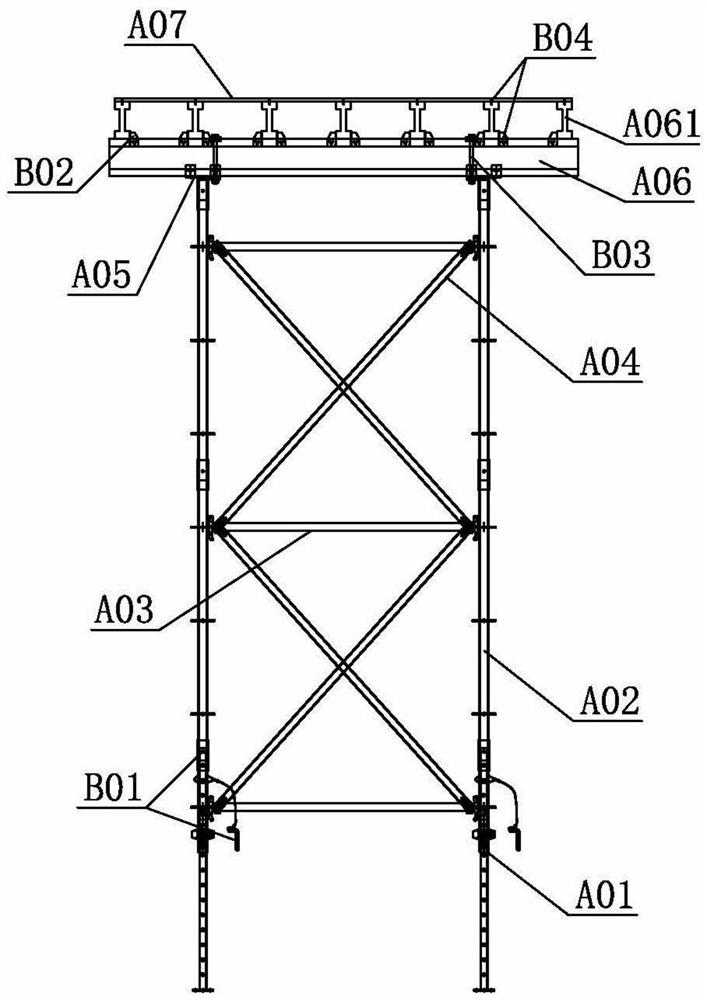

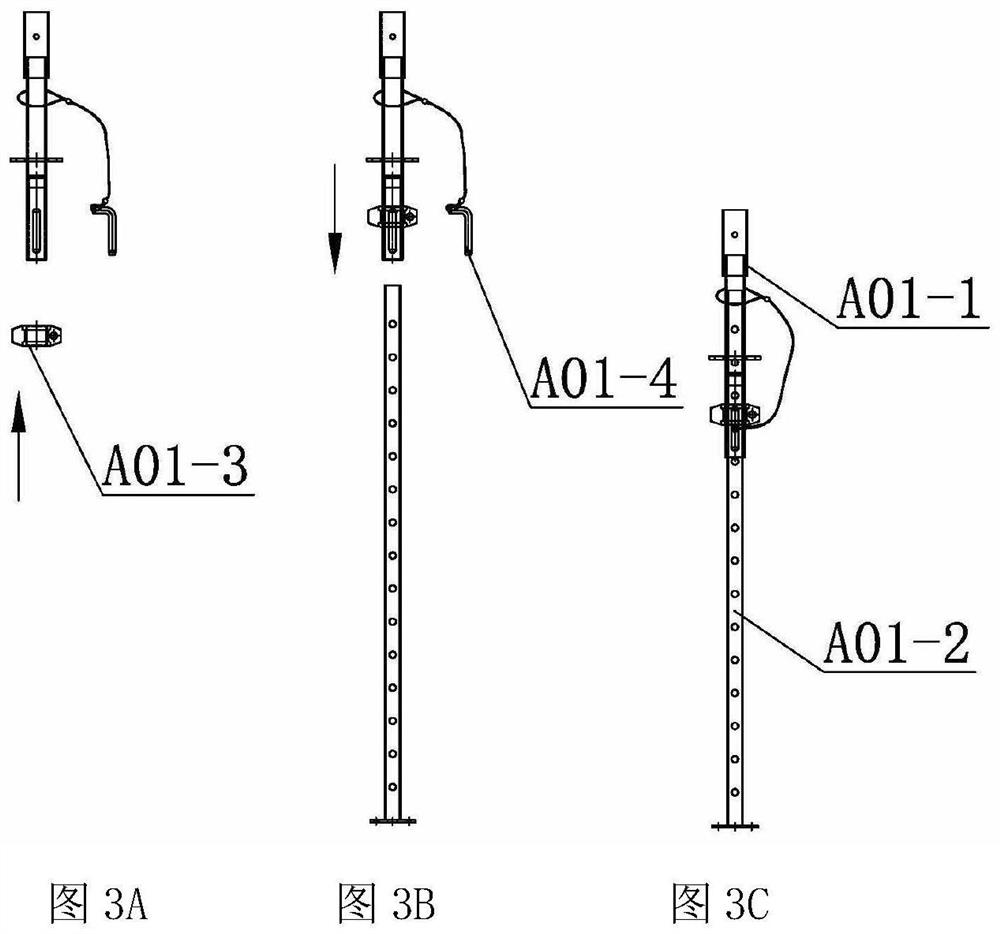

[0032] The technical solutions in the embodiments of the present application will be clearly and completely described below in conjunction with the accompanying drawings.

[0033] Such as figure 1 As shown, a scaffolding table form without disassembly of the disc buckle of the present invention has the characteristics of high bearing capacity, large adjustment range, different specifications, no disassembly and assembly, and reduced cost compared with similar products, and can be applied to high-rise buildings. Concrete construction of horizontal structures such as super high-rise buildings, multi-storey industrial plants, and underground structures. It includes a support system A that can be raised repeatedly, and the upper end of the support system A is provided with a formwork system B. The support system A includes a frame composed of vertical rods and horizontal rods, the vertical rods are connected around by diagonal rods, and the horizontal rods and diagonal rods are c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com