Engine

An engine and body technology, applied in engine components, machines/engines, mechanical equipment, etc., can solve the problems of high cost, complex engine structure, poor reliability, etc., and achieve the effects of low cost, simple structure and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

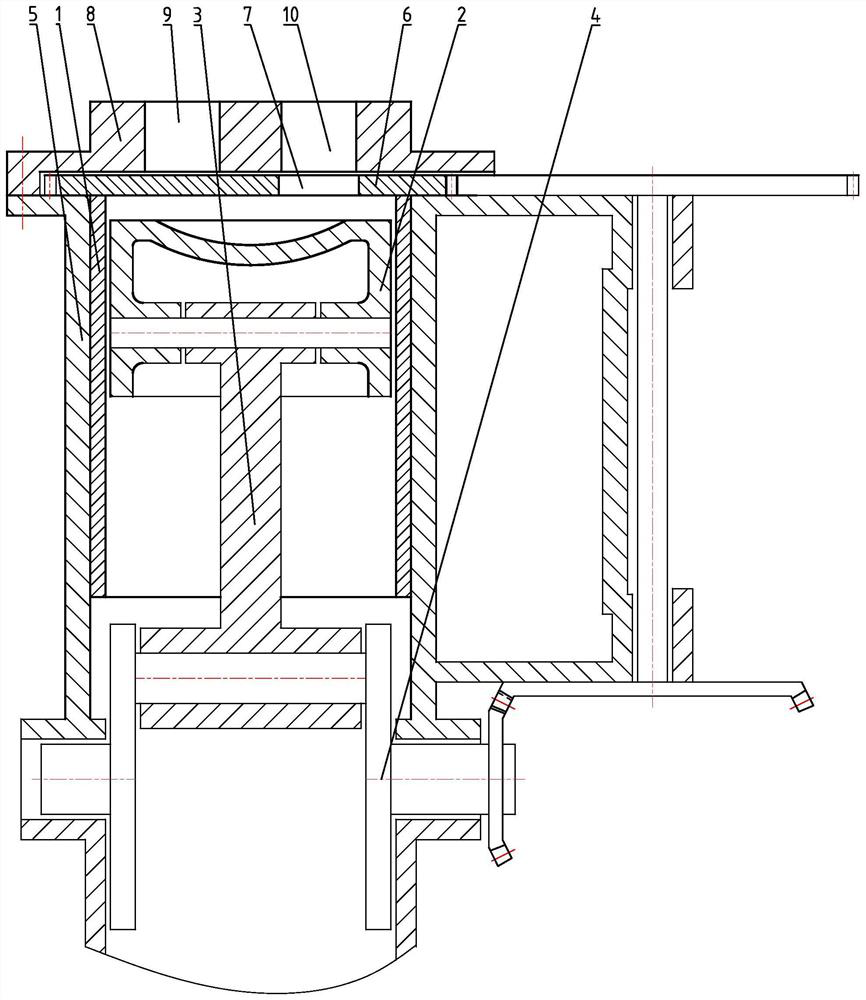

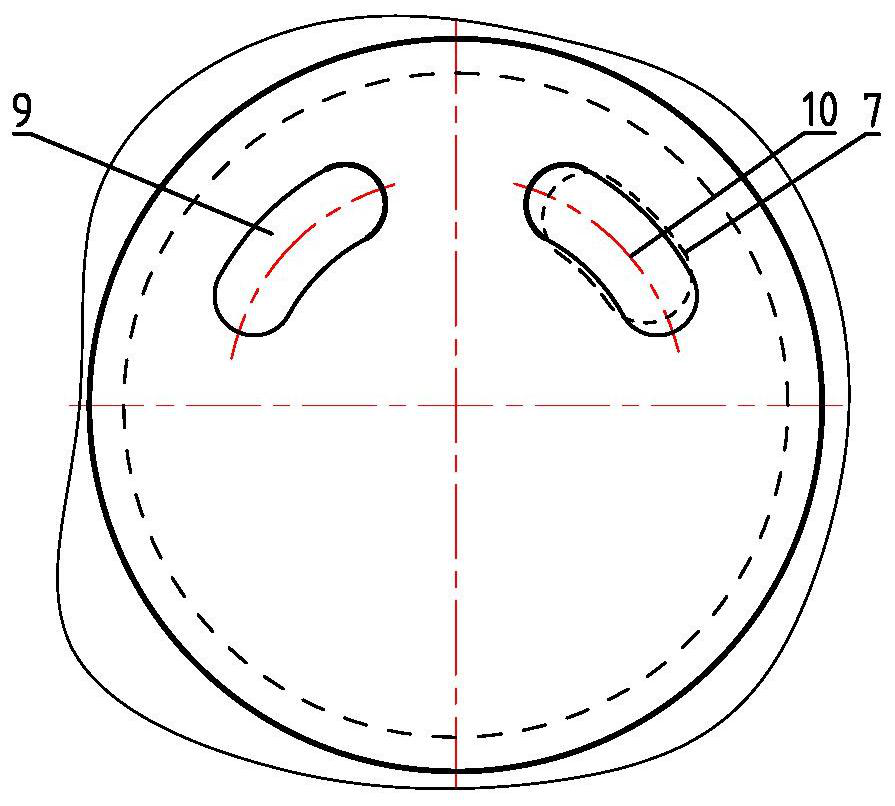

[0029] An engine comprises a cylinder 1, a piston 2, a connecting rod 3 and a crankshaft 4, the cylinder 1 is arranged on a body 5, a rotating sealing body 6 is arranged on the body 5, the cylinder 1 and the rotating sealing body 6 is cooperatingly arranged, a gas distribution port 7 is set on the rotating sealing body 6, the piston 2 is set in the cylinder 1, the piston 2 is set through the transmission of the connecting rod 3 and the crankshaft 4, and the rotating The sealing body 6 is driven and rotated by the crankshaft 4, the gas distribution port 7 is arranged in cooperation with the cylinder head 8, an air inlet 9 and an exhaust port 10 are arranged on the cylinder head 8, and the piston 2 and the cylinder 1 works in a four-stroke working mode or the piston 2 and the cylinder 1 work in a two-stroke working mode.

Embodiment 2

[0031] An engine comprises a cylinder 1, a piston 2, a connecting rod 3 and a crankshaft 4, the cylinder 1 is arranged on a body 5, a rotating sealing body 6 is arranged on the body 5, the cylinder 1 and the rotating sealing body 6 is cooperatingly arranged, a gas distribution port 7 is set on the rotating sealing body 6, the piston 2 is set in the cylinder 1, the piston 2 is set through the transmission of the connecting rod 3 and the crankshaft 4, and the rotating The sealing body 6 is driven and rotated by the crankshaft 4, the gas distribution port 7 is arranged in cooperation with the cylinder head 8, an air inlet 9 and an exhaust port 10 are arranged on the cylinder head 8, and the rotating speed of the rotating sealing body 6 The rotation speed of the crankshaft 4 is half, and the piston 2 and the cylinder 1 work in a four-stroke working mode.

Embodiment 3

[0033] An engine comprises a cylinder 1, a piston 2, a connecting rod 3 and a crankshaft 4, the cylinder 1 is arranged on a body 5, a rotating sealing body 6 is arranged on the body 5, the cylinder 1 and the rotating sealing body 6 are arranged in cooperation, and the air distribution port A and the air distribution port B are arranged on the rotating sealing body 6, the piston 2 is arranged in the cylinder 1, and the piston 2 is set through the transmission of the connecting rod 3 and the crankshaft 4 , the rotating sealing body 6 is driven and rotated by the crankshaft 4, the gas distribution port A and the gas distribution port B are arranged in cooperation with the cylinder head 8, and an air inlet 9 and an exhaust port are arranged on the cylinder head 8 10. The rotational speed of the rotating sealing body 6 is half of the rotational speed of the crankshaft 4, and the piston 2 and the cylinder 1 work in a two-stroke working mode.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com