Electromagnetic ultrasonic stress detection device for oil and gas pipeline and detection method thereof

An electromagnetic ultrasonic, oil and gas pipeline technology, applied in measuring devices, using stable tension/pressure to test the strength of materials, instruments, etc., can solve the problems of inaccurate measurement accuracy of pipeline flaw detection and great influence on accuracy, and achieve assembly time. Reduce, improve accuracy, improve assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

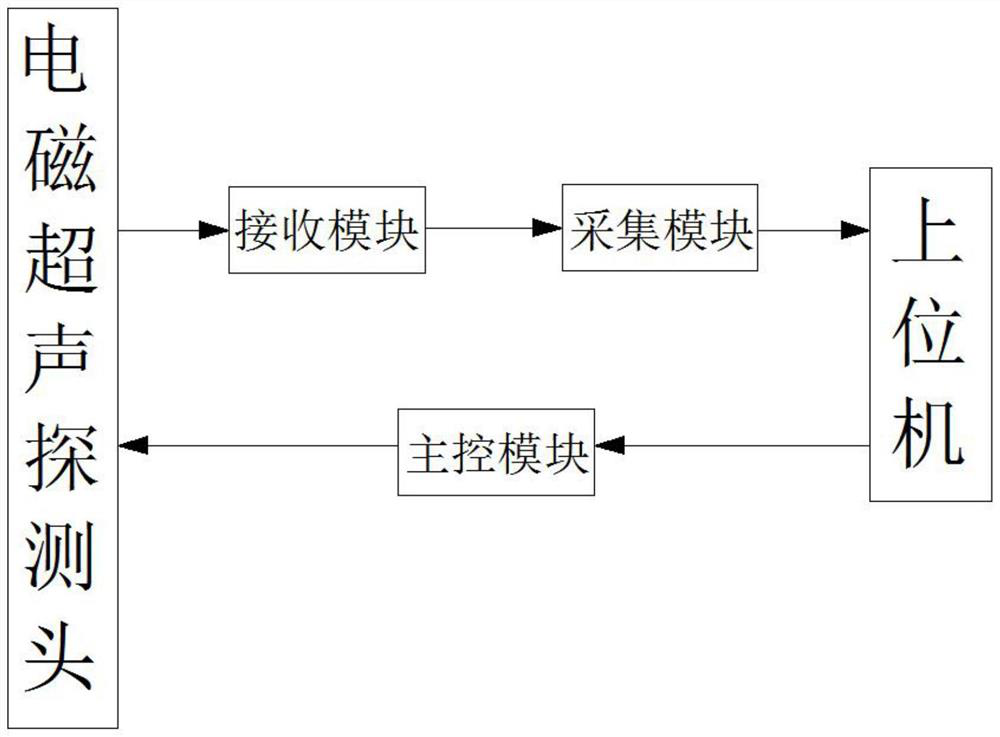

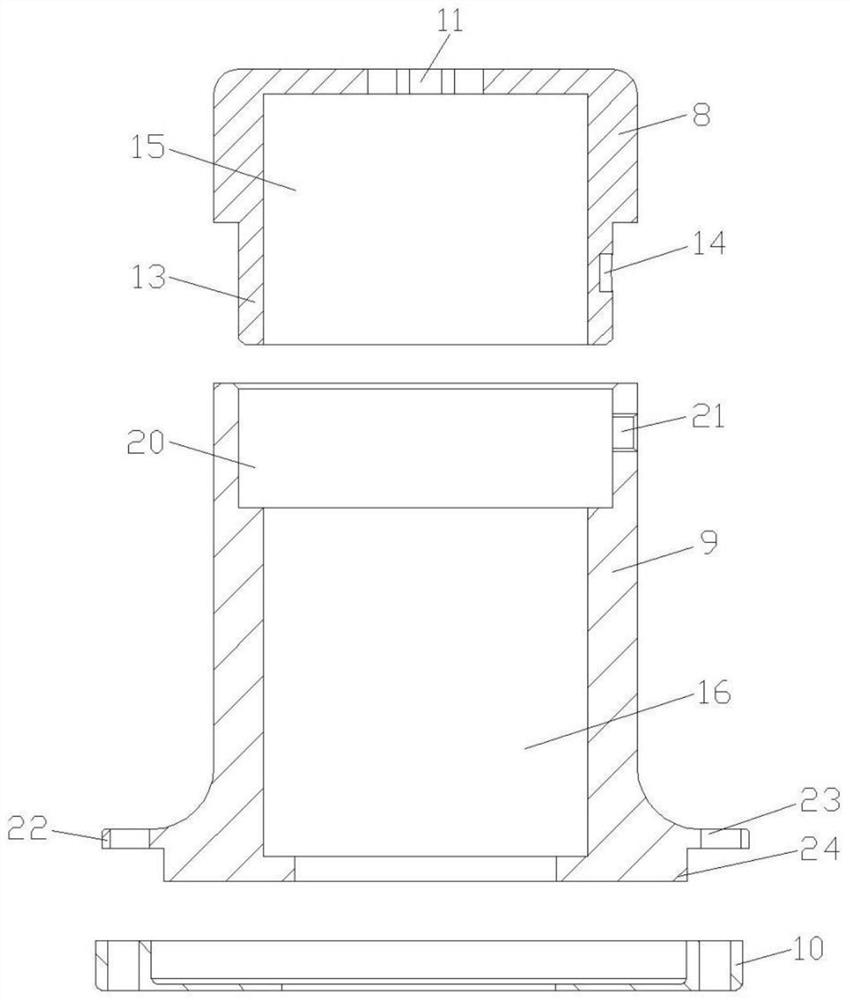

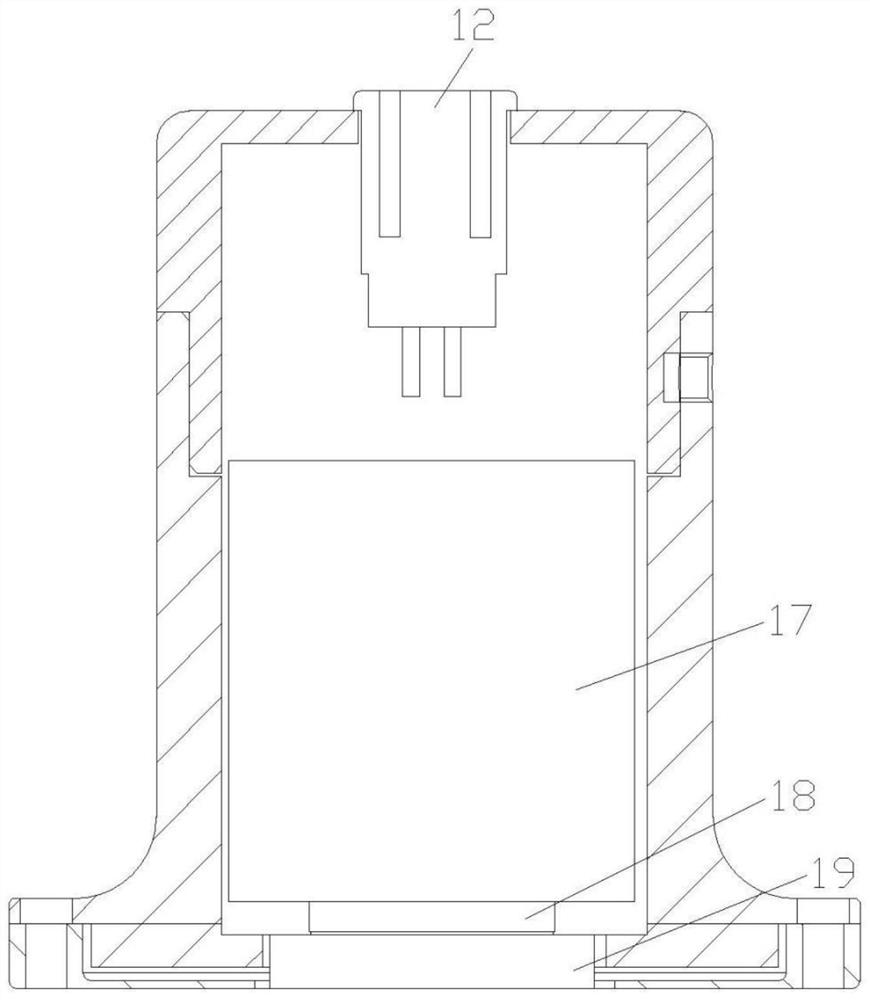

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0029] refer to figure 1 , the present invention provides an electromagnetic ultrasonic stress detection device for oil and gas pipelines, comprising an electromagnetic ultrasonic probe, the magnetic ultrasonic probe is electrically connected to a receiving module for receiving signals, the receiving module is electrically connected to an acquisition module, and the acquisition module is electrically Connect the upper computer, the upper computer is electrically connected to the main control module, the main control module is electrically connected to the electromagnetic ultrasonic probe, the upper computer is connected to the acquisition module and the main control module through the USB cable, and the signal acquisition and the control of the main control module are completed respectively Function: the acquisition module collects the amplified signal from t...

Embodiment 2

[0037] A detection method for an electromagnetic ultrasonic stress detection device for oil and gas pipelines, the method includes the following steps:

[0038] S01. Calibration oil pipeline processing and residual stress removal treatment:

[0039] The material of the oil pipeline is X65 pipeline steel, and the stretching direction of the oil pipeline is divided into axial direction and circumferential direction. Residual stress treatment adopts annealing stress relief process.

[0040]S02. When measuring sound in tensile test:

[0041] The electromagnetic ultrasonic probe is adsorbed on the calibrated part of the oil pipeline, and the pulling force is applied in a step-by-step manner to measure the sound time value under each pulling state.

[0042] S03, into the equation to solve the acoustic elastic parameters:

[0043] According to the structure of the equation, the unknown parameters in the equation are obtained by means of data fitting.

[0044] S04. Error analysis:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com