Temperature heating instrument for gas conveying pipeline of thermogravimetric analyzer

A thermogravimetric analyzer and gas pipeline technology, which is applied in the direction of thermal analysis of materials, analytical materials, preparation of samples for testing, etc. Reduce the possibility of clogging the trachea, reduce heat loss, and have a significant thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Specific implementation plan

[0022] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENT OF THE INVENTION OF THE INVENTION OF THE INVENTION OF THE INVENTION The following examples are described below in connection with the accompanying drawings. Based on the embodiments in the present invention, there are all other embodiments obtained without making creative labor premises, in the preceding embodiments of the present invention.

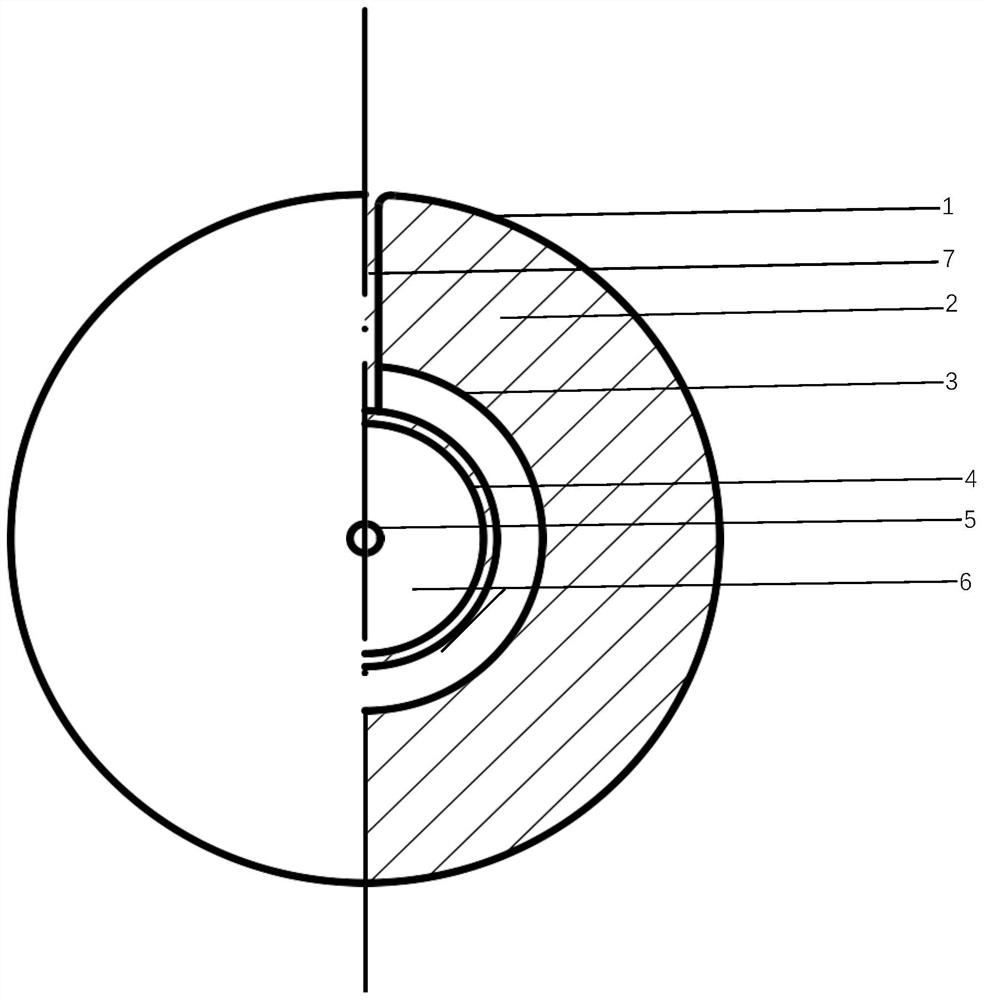

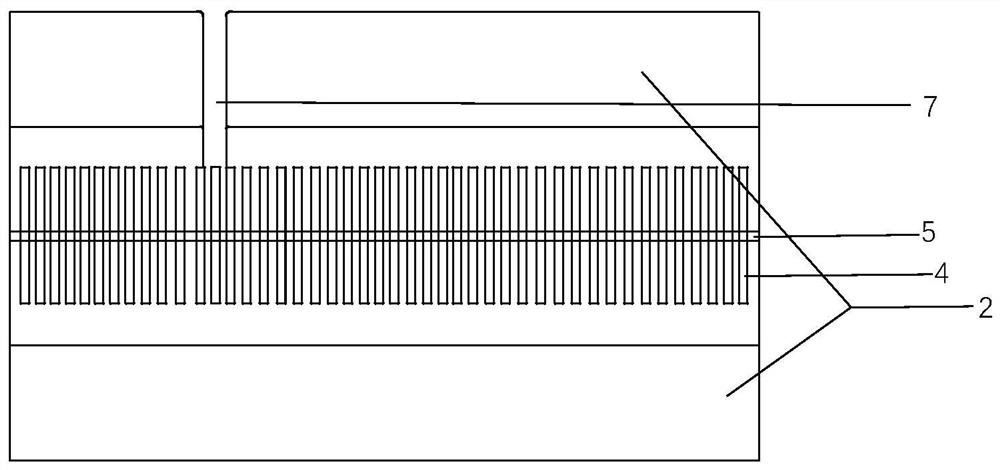

[0023] like figure 1 and 2 As shown, the present invention provides a resistor wire to the gas barrel, and the heating of the controller is controlled. The heat insulating thermal layer includes an aluminum outer casing and an inner casing that performs high vacuum treatment therefrom, sealing treatment in the pipe start end and the end, only the air supply soft tube can be left. The connection resistance wire is applied to the control terminal to protect the heat insulating layer to ensure the sealing of the insulation layer. Gas filling inside the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com