Time-resolved polycrystalline x-ray diffraction target device

A time-resolved, X-ray technology, used in measurement devices, analyzing materials, and material analysis using wave/particle radiation. It can solve problems such as insensitivity to structural changes, low timing synchronization accuracy, and poor time resolution. High signal-to-noise ratio, high timing synchronization accuracy and good time resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the purpose, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the examples and accompanying drawings. As a limitation of the present invention.

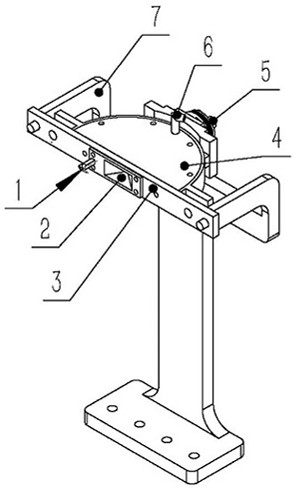

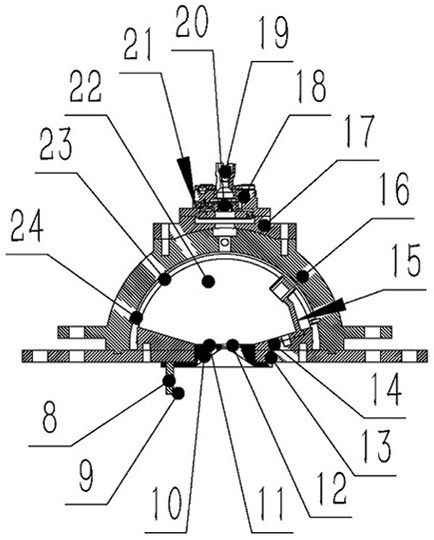

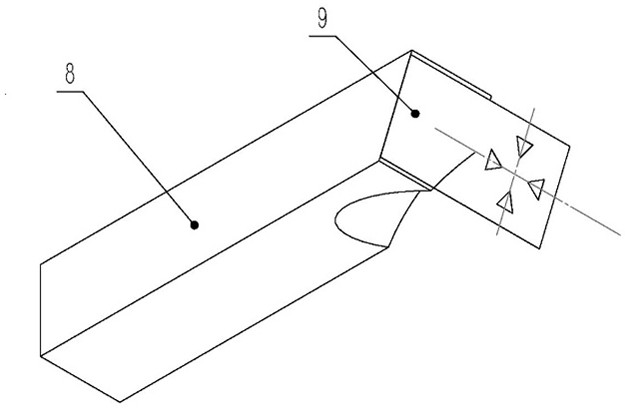

[0041] Such as figure 1 , figure 2 As shown, this embodiment provides a time-resolved polycrystalline X-ray diffraction target device, including: a backlight X-ray target assembly 1, which is used to generate pulsed X-rays for transient X-ray diffraction diagnosis of polycrystalline targets at different time sequences The laser-driven loading target assembly 2 is connected to the backlight X-ray target assembly 1, and is used to simulate the shock compression process produced by the high-speed impact or detonation process of the polycrystalline target. The laser-driven loading target assembly 2 is provided with at least one diffraction hole 12, Diffraction hole 12 is used as the optical path of pulsed X-r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com