Lithium battery pressing plate assembling machine with positioning and antiskid functions

A technology of a lithium battery and a pressure plate group is applied in the field of lithium battery pressure plate assembly machines with positioning and anti-skid function, which can solve the problems of inconvenient transportation of lithium battery pressure plates and inconvenience of synchronous loading and processing of pressure plates, so as to achieve the effect of facilitating assembly and avoiding congestion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

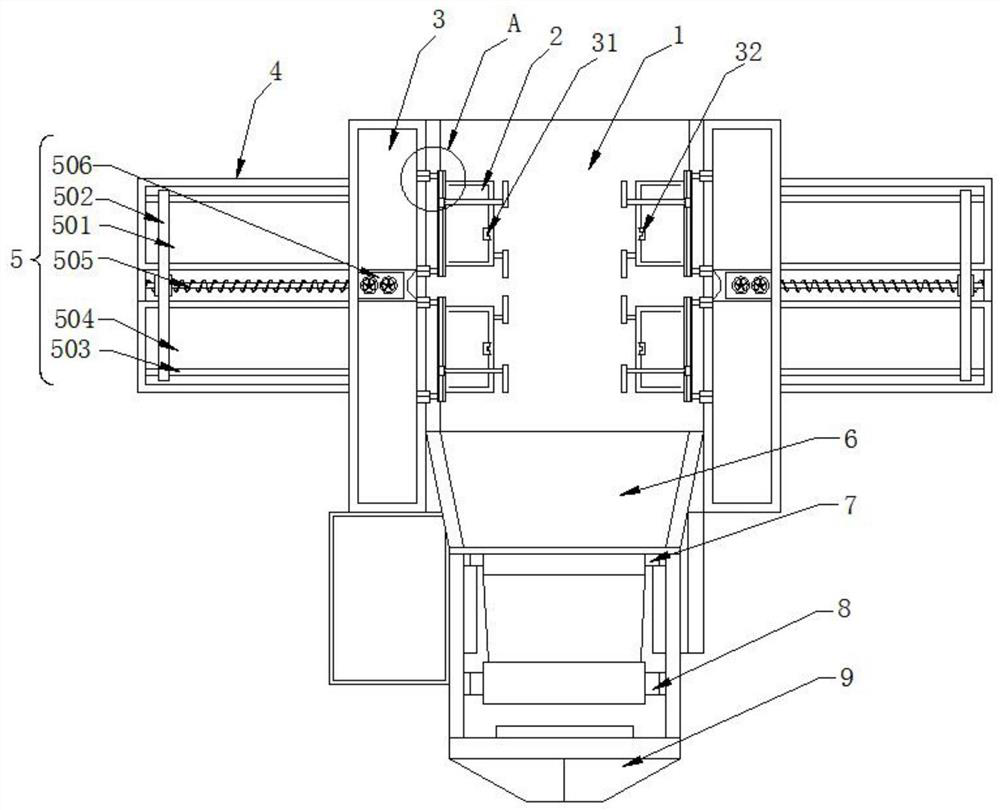

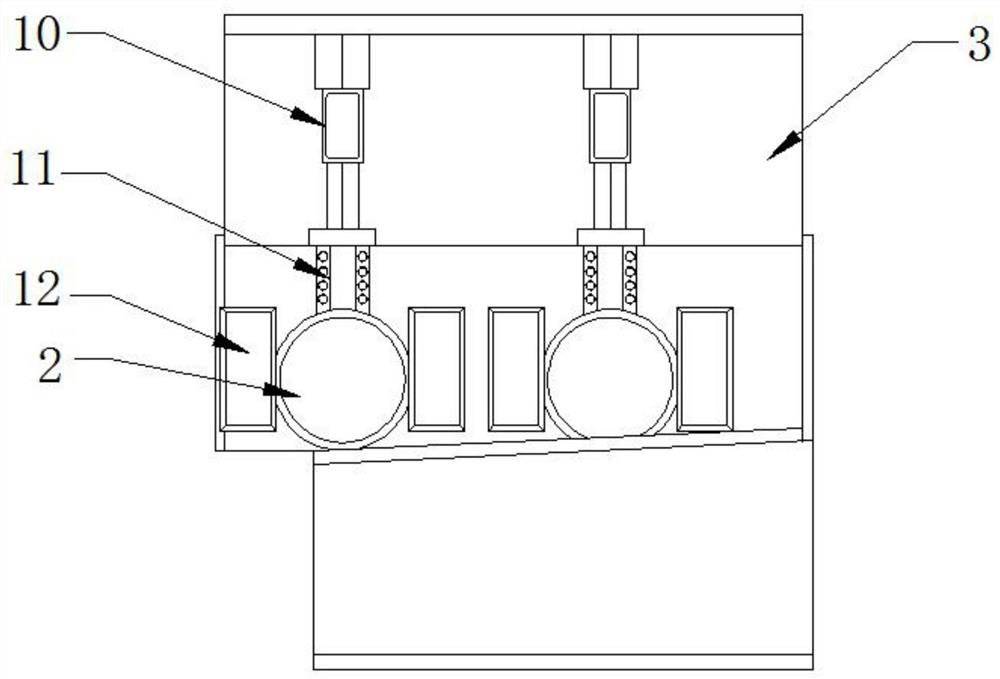

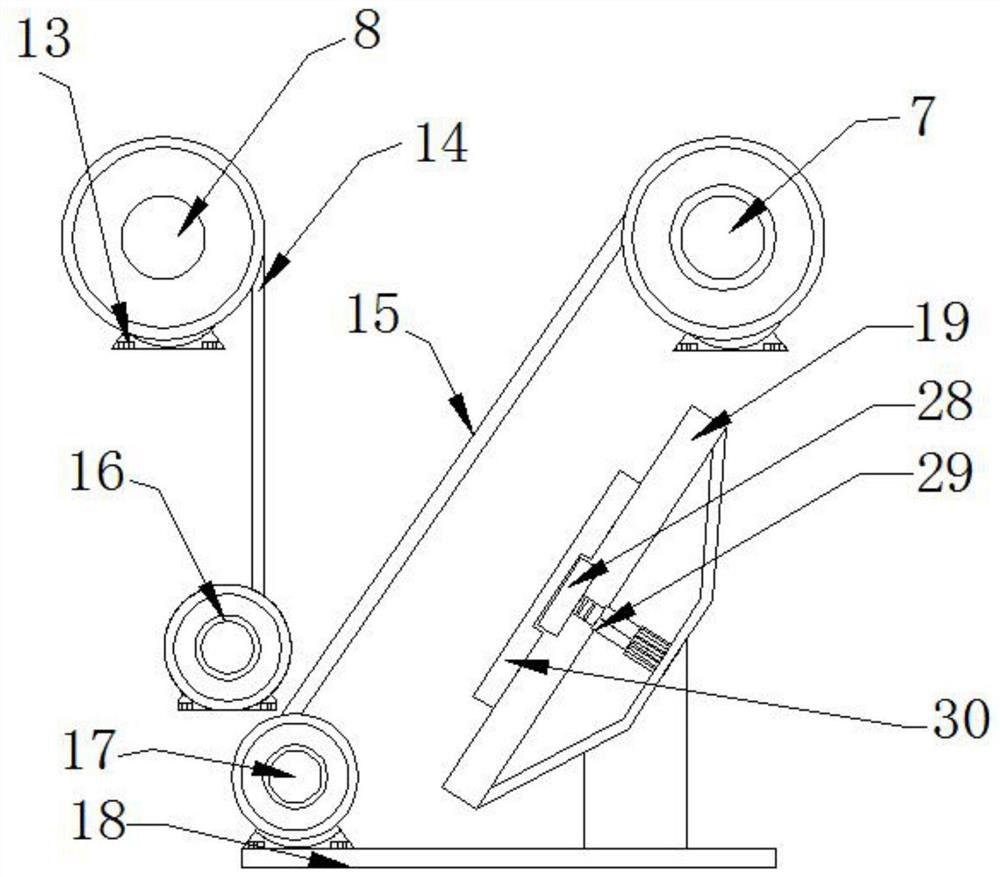

[0029] see Figure 1 to Figure 6, the present invention provides a technical solution: a lithium battery press plate assembly machine with positioning anti-slip function, including a connecting plate 1, a blanking frame 2, an auxiliary side frame 3, a side main frame 4, a feeding assembly 5, and a first accommodation chamber 501, push plate 502, guide rod 503, second accommodation chamber 504, screw rod 505, servo motor chamber 506, swash plate 6, first rewinding shaft 7, second rewinding shaft 8, auxiliary frame 9, first hydraulic air rod 10. Adapter block 11, adjustment plate 12, motor 13, dustproof film 14, rear dustproof film 15, bottom reel 16, auxiliary bottom reel 17, bottom plate 18, connection cavity 19, first electric push rod 20, card Block 21, sizing frame 22, second hydraulic air rod 23, slider 24, connecting rod 25, electric slide rail 26, heating plate 27, auxiliary block 28, second electric push rod 29, rear sizing frame 30, Infrared spotlight 31 and mapping b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com