Rotary driving system and engineering machine

A technology of rotary drive and system oil, which is applied in the field of hydraulic systems and can solve problems such as pressure loss increase, power loss, and complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The core of the present invention is to provide a slewing drive system, which controls whether the auxiliary motor is connected to the main oil circuit through the shift valve, realizes gear switching, simple and reliable oil circuit, and reduces cost, system heat generation and power loss. Another core of the present invention is to provide a construction machine including the above-mentioned slewing drive system.

[0024] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

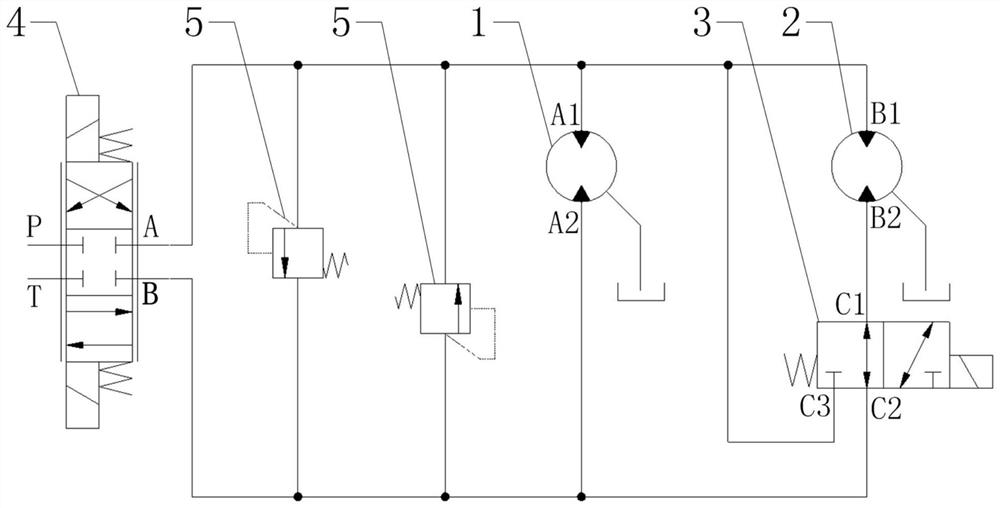

[0025] Please refer to figure 1 , figure 1 It is a hydraulic principle diagram of a specific embodiment of the slewing drive system provided by the present invention.

[0026] The specific embodiment of the present invention provides a rotary drive system, including a system oil source 6, a main motor 1, an aux...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com