Solid-sealed polar pole of annular capacitor

A technology of solid-sealed poles and capacitors, which is applied to circuits, electric switches, electrical components, etc., can solve the problems of casting molding yield and reliability decline, increased manufacturing and construction difficulty, and large volume and weight of poles. Insulation withstand ability, good temperature application ability, effect of improving safety margin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

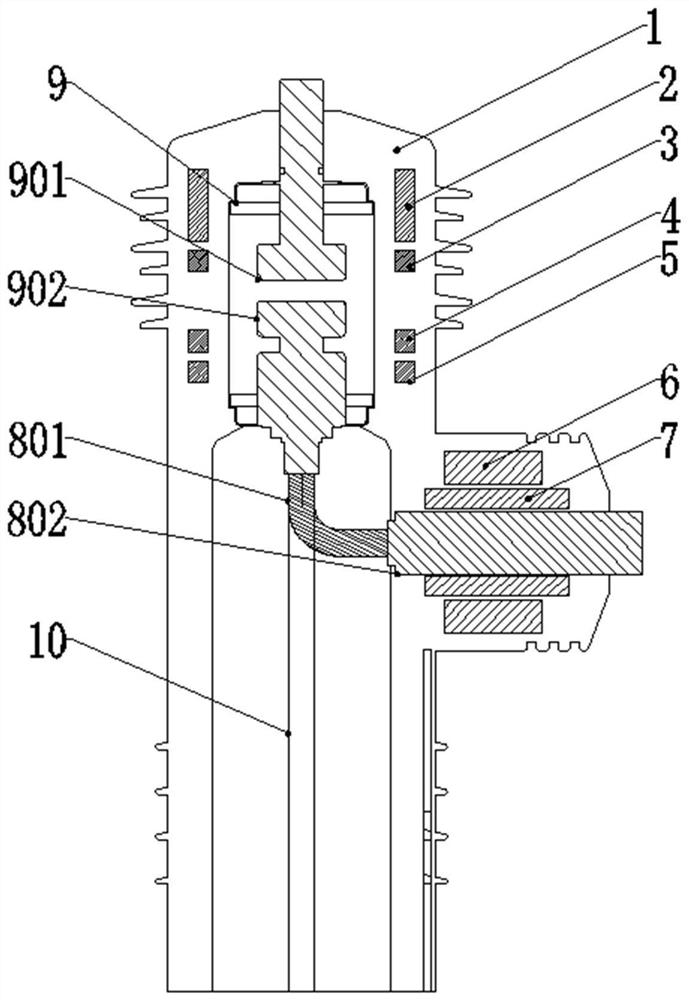

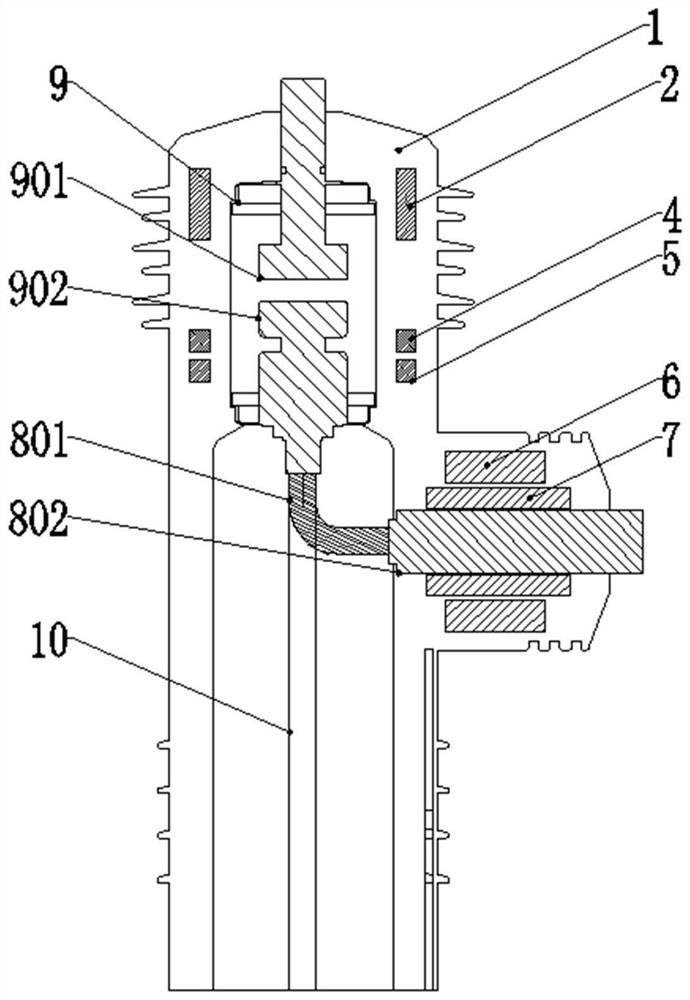

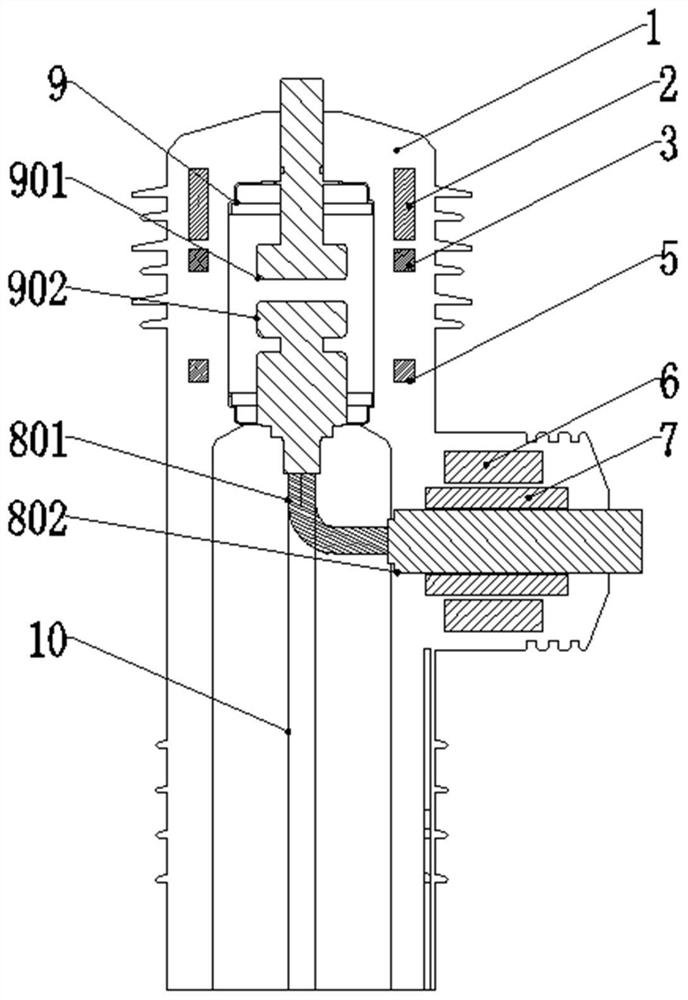

[0022] The technical solutions and beneficial effects of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0023] The invention discloses a solid-sealed pole of an annular capacitor. The upper energy-taking capacitor and the upper phase-sequence measurement capacitor are made of ceramic capacitors, which are designed as rings with the same inner and outer diameters, and coaxially cast on the periphery of the vacuum circuit breaker, and It is placed at the position of the static contact of the vacuum circuit breaker so that the high voltage electrode and the static contact of the vacuum circuit breaker have the same potential.

[0024] The lower phase sequence measurement capacitor and the zero sequence measurement capacitor are designed as rings with the same inner and outer diameters, coaxially cast on the periphery of the vacuum circuit breaker, and placed at the position of the moving contact of the vacuum circuit breake...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com