Compressible uv-activatable or thermally activatable (semi-) structural adhesive film that changes color after activation and after curing

A color changing, adhesive film technology, applied in the direction of heat activated films/sheets, non-polymer adhesive additives, adhesive types, etc., which can solve the problem of no longer ensuring adhesion, lack of adhesion of second joint parts power and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

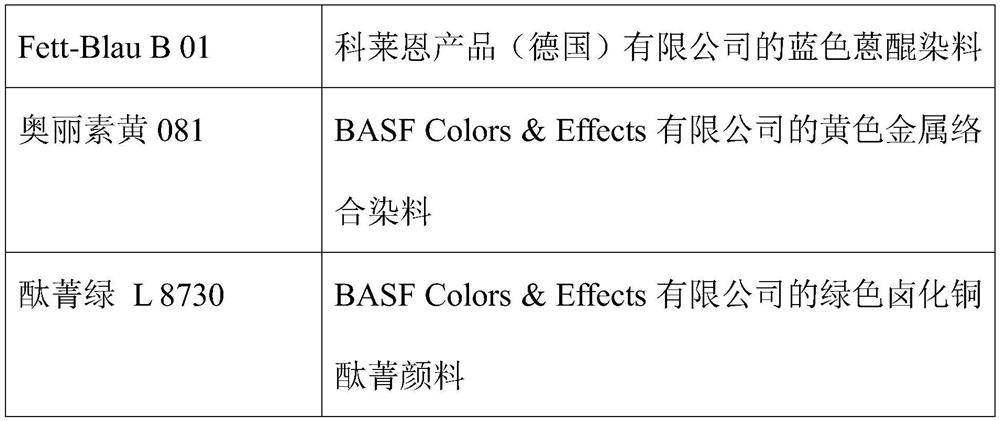

[0120] Examples of compositions relevant to the selection of expandable fillers are summarized in Table 3, where the quantity statements represent parts by weight. K1 to K3 are formulations according to the invention with expandable fillers. V1 is an adhesive transfer film without the addition of expandable fillers:

[0121] Example: K1 K2 K3 V1 Phenoxy resin PKHH-25-B 40.0 40.0 40.0 40.0 D.E.R 331 17.5 17.5 17.5 17.5 D.E.R.736 13.4 13.4 13.4 13.4 Struktol Polycavit 3550 25.0 25.0 25.0 25.0 Araldite DY 3601 4.1 4.1 4.1 4.1 Omnicat 432 1.5 1.5 1.5 1.5 Dynadylan GLYEO 0.7 0.7 0.7 0.7 Microsphere F-35D 6.3 - - - Microsphere F-36D - 6.3 - - Expancell 920DU 40 - - 6.3 - methyl ethyl ketone 55.2 55.2 55.2 55.2

[0122] table 3

[0123] In Table 4 the results of the tensile shear tests, tensile and peel tests and the associated expansion and compression ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com