Hydrogen gas nozzle provided with anti-backfire structure and used for hydrogen machine and hydrogen absorption device comprising same

A technology of anti-tempering and hydrogen, applied in the direction of respirators, etc., can solve the problems of burning pipelines, explosion accidents, etc., and achieve the effect of reducing the propagation speed and increasing the cooling area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

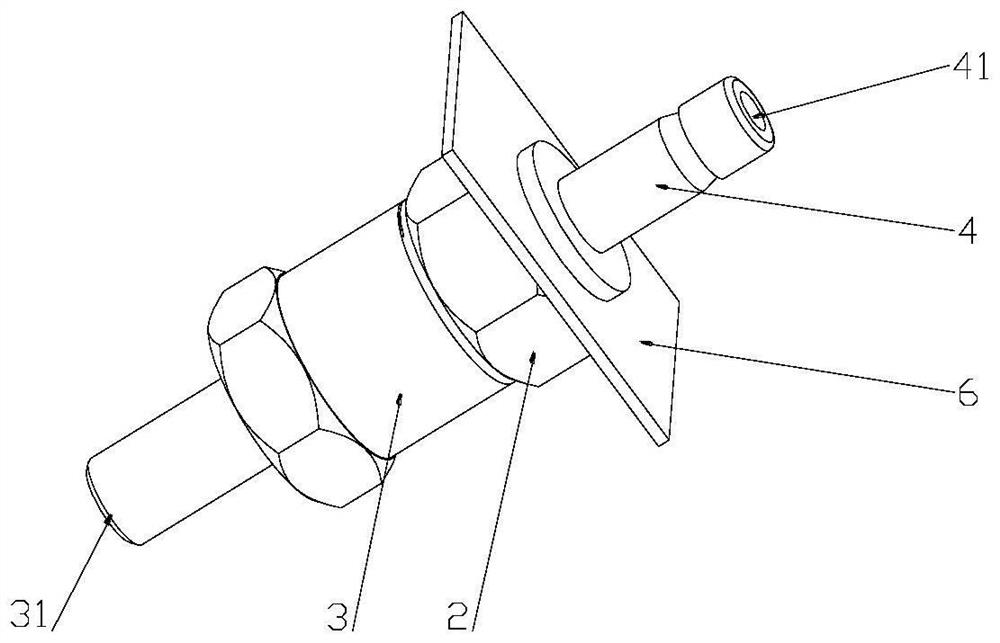

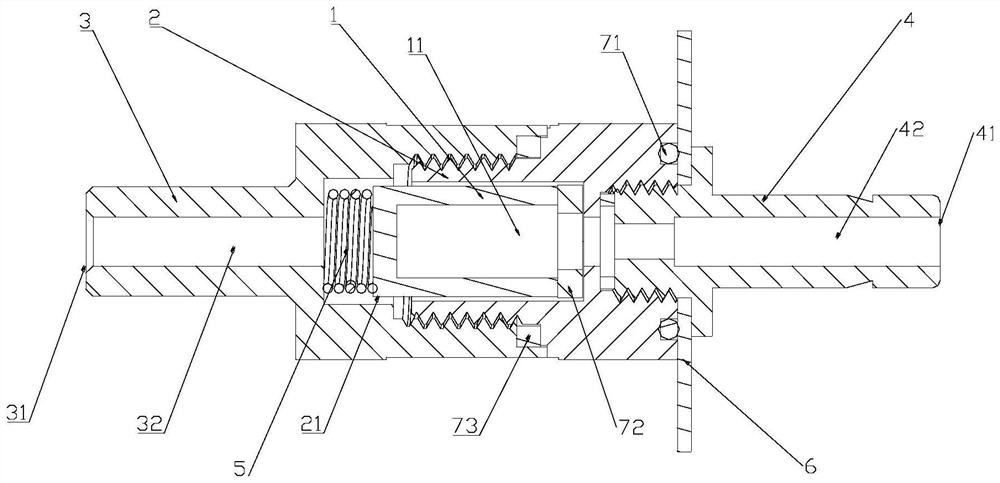

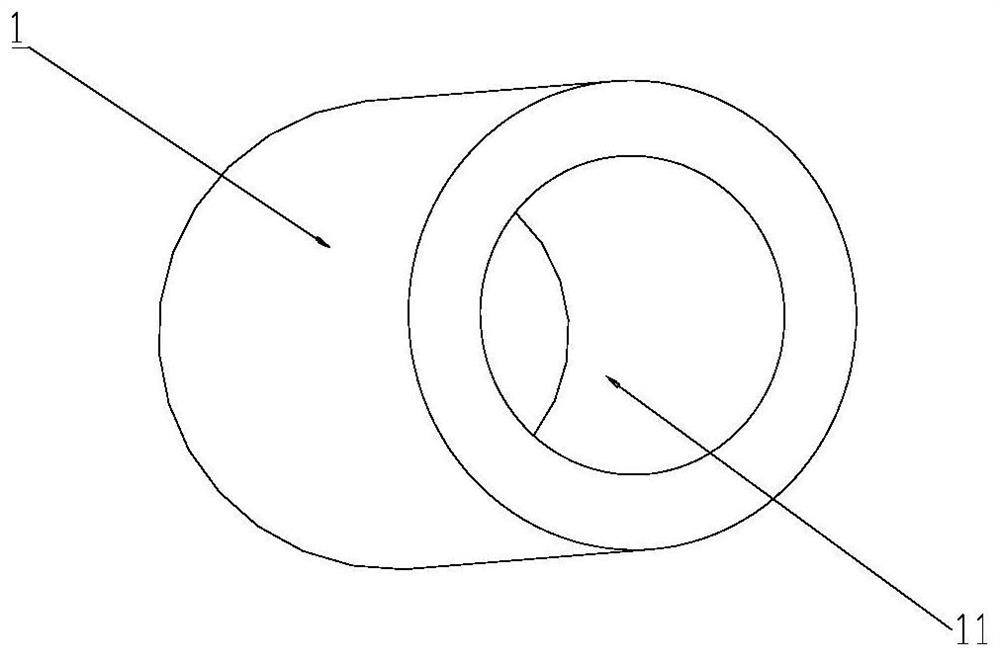

[0031] like Figure 1-3 As shown, a hydrogen gas nozzle with an anti-tempering structure for a hydrogen generator provided in this embodiment includes a gas nozzle body, and two ends of the gas nozzle body are respectively provided with an air inlet 31 and an air outlet 41. The air inlet 31 and the gas outlet 41 are connected with a gas nozzle channel 21 for gas to pass through. The gas nozzle channel 21 is provided with a porous component 1. The porous component 1 has dense pores for hydrogen to pass through. After generation, it flows in the direction of the air outlet 41 through the air inlet 31 . The focus of blocking flashback is to reduce the flame propagation speed and reduce the temperature. The diameter of the combustion channel has a significant effect on the flame propagation speed, and the flame propagation speed generally decreases with the decrease of the diameter of the channel. During the tempering process of this embodiment, the propagation of the burning fl...

Embodiment 2

[0040] like Figure 4-5 As shown, a hydrogen absorption device provided in this embodiment, specifically a humidification cup, is used to humidify the gas generated by the hydrogen generator. The humidification cup is filled with water, and the gas to be treated is introduced below the water surface through the gas pipeline. When the dissolved gas in the water is saturated, the gas flows out from the water in the form of bubbles from above the water surface, and finally is supplied to the user through the air outlet channel. End suction. After humidification by the humidification cup, the water content of the gas increases, and the water has a filtering effect on the gas, so that the inhaled gas is cleaner and the inhalation experience is more comfortable.

[0041] The humidification cup of this embodiment includes a cup body 81, a gas delivery pipe 82 for delivering gas to the cup body, and an air outlet channel 83 for outputting the humidified gas. The air outlet channel 83...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com