Clean channel system for large component purification

A large component, clean technology, applied in the field of purification, can solve the problems of low automation, poor cleaning effect, inability to clean and dry large components, etc., and achieve the effect of high automation and good ability to clean large components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

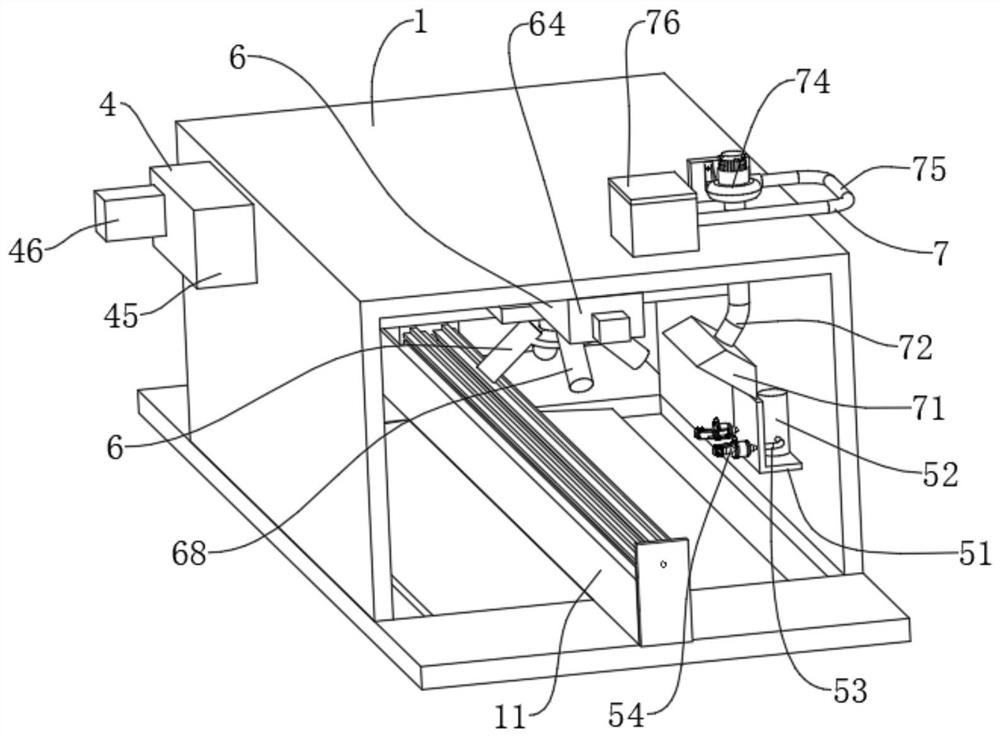

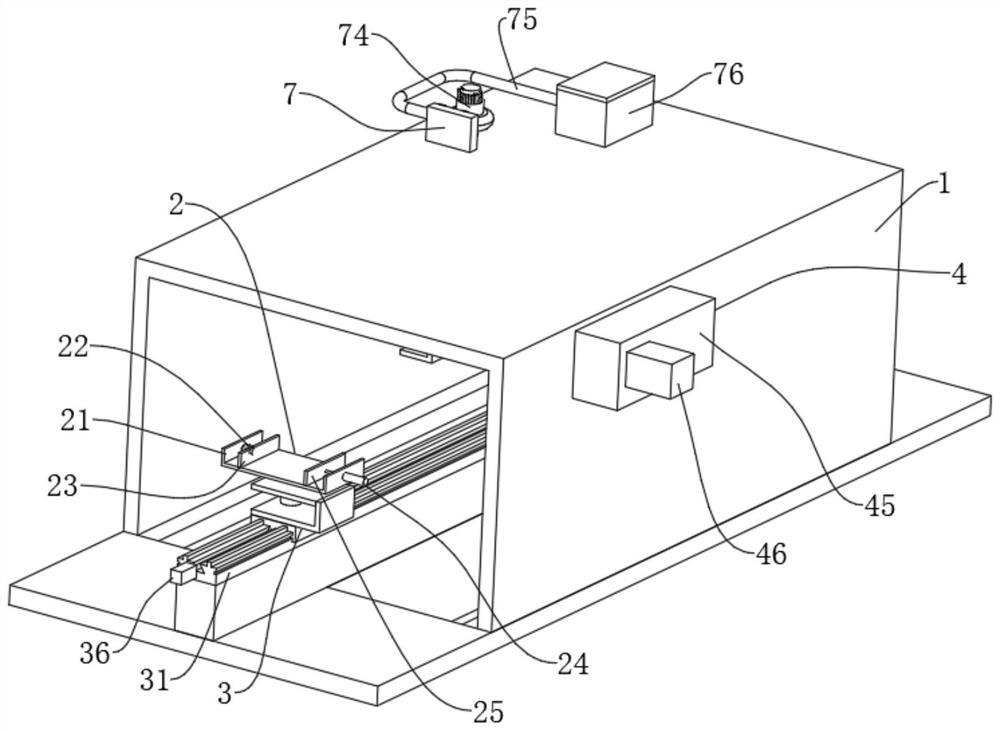

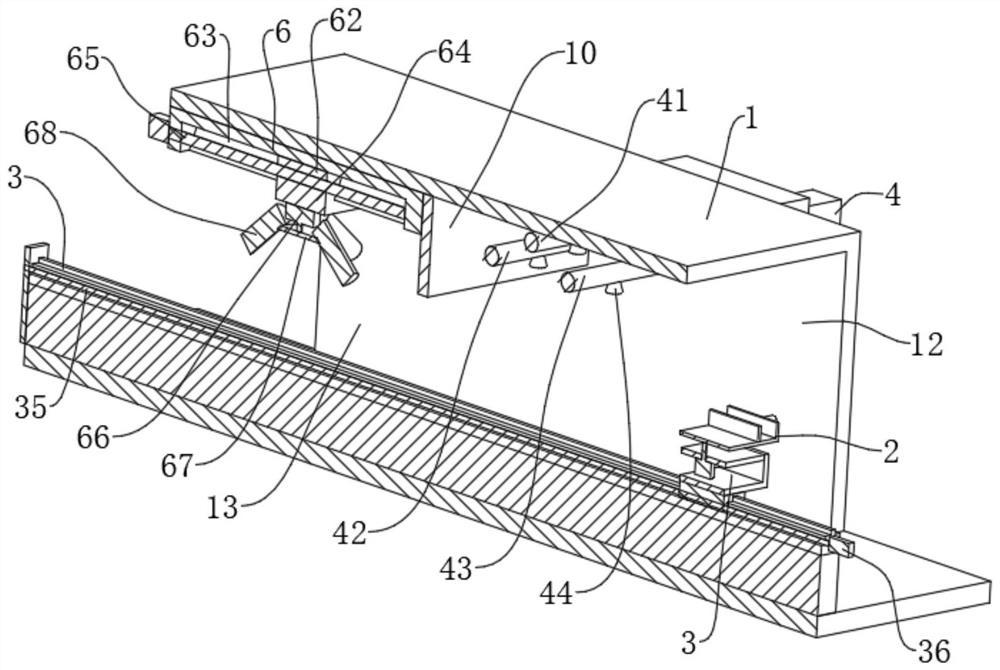

[0044] refer to figure 1 , figure 2 and image 3 , a clean channel system for purification of large components, a clean channel system for purification of large components, comprising a clean room 1, further comprising: a hermetic door arranged at openings on both sides of said clean room 1; arranged in said clean room 1 The fixed seat 11; the fixed assembly 2 used to fix large components; the power assembly 3 used to drive the fixed assembly 2 for horizontal transmission and rotation change; the partition plate 10 fixed on the top of the clean room 1, the The partition plate 10 divides the clean room 1 into a first chamber 12 and a second chamber 13; the spray assembly 4 arranged in the first chamber 12 for spray cleaning; The blowing assembly 5 in the second chamber 13; the air-heating assembly 6 arranged on the side wall of the second chamber 13; and the ventilation and ventilation assembly 7 for ventilation.

[0045] refer to figure 1 , figure 2 and image 3 , this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com