Preparation method of aluminum-based composite material with controllable reinforcement phase distribution

An aluminum-based composite material and reinforcing phase technology, applied in metal material coating process, manufacturing tools, welding equipment and other directions, can solve the problems affecting the performance of materials, the interface is not firmly bonded, etc., and achieve the effect of excellent strong plastic bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

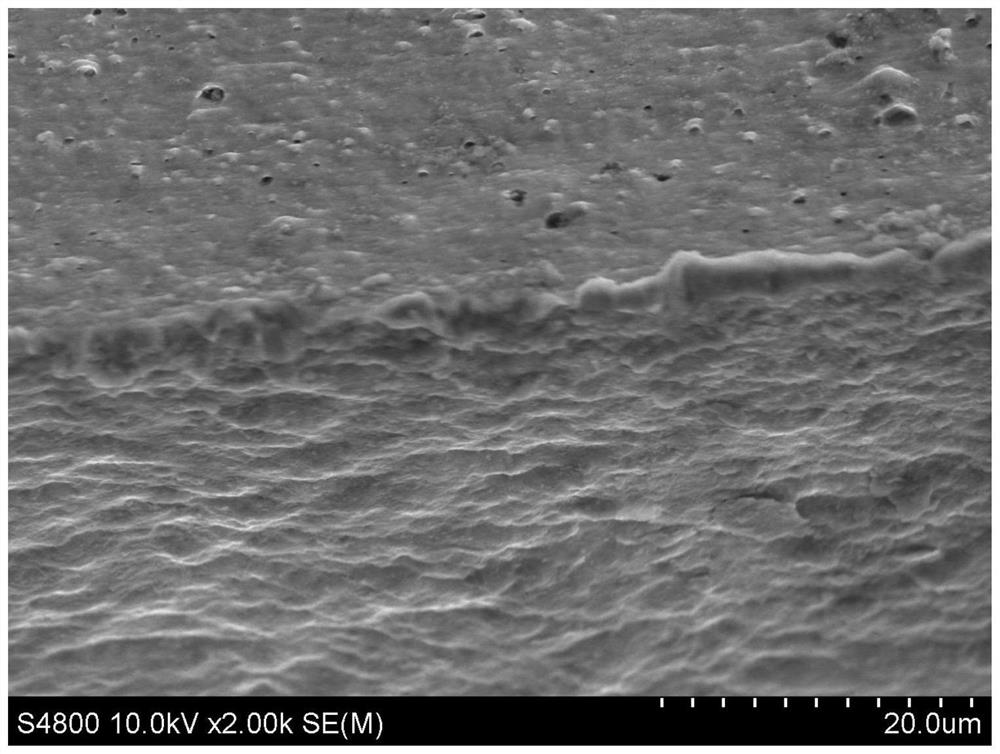

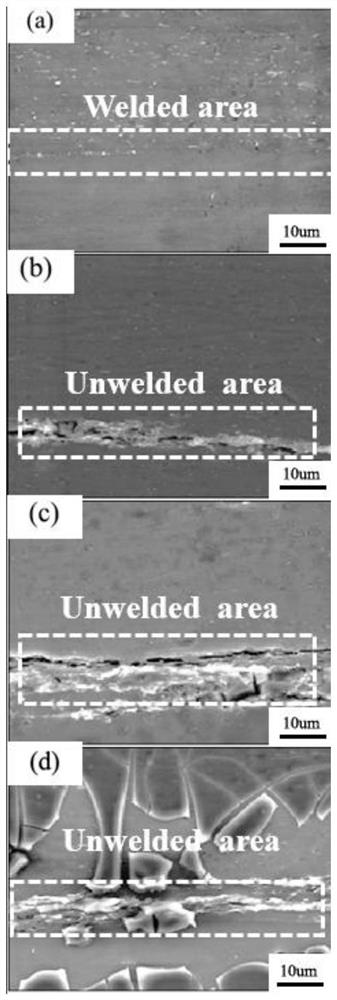

Image

Examples

Embodiment Construction

[0031] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention. Unless otherwise specified, the examples are all in accordance with conventional experimental conditions. In addition, for those skilled in the art, on the premise of not departing from the spirit and scope of the present invention, various modifications or improvements to the material components and dosage in these embodiments all belong to the protection scope of the present invention.

[0032] The preparation method of aluminum matrix composite material with controllable reinforcement phase distribution comprises the following steps in sequence:

[0033] S1, aluminum alloy plate oxidation treatment:

[0034] First, use the DK7735 electric discharge numerical control wire cutting machine to cut the aluminum alloy plate with a thickness of 5mm, and use the grinder to polish the surface of the aluminum alloy plate;

[0035] Then, oxidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com