Metal surface heat treatment device and method

A heat treatment device and metal surface technology, applied in the field of heat treatment, can solve the problems of increasing the workload of the staff, the danger of the staff, and the low work efficiency, and achieve the effects of shortening the time, reducing the labor intensity, and improving the effect and efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is not limited by the following examples, and specific implementation methods can be determined according to the technical solutions of the present invention and actual conditions.

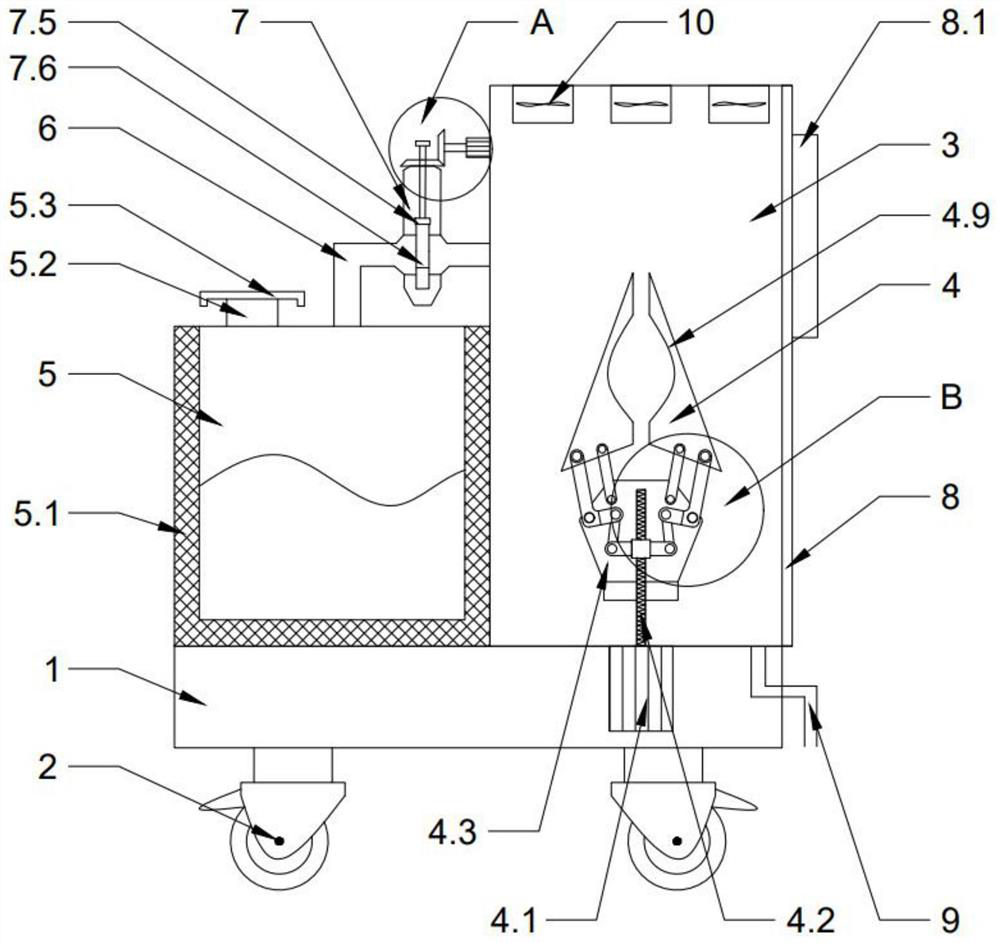

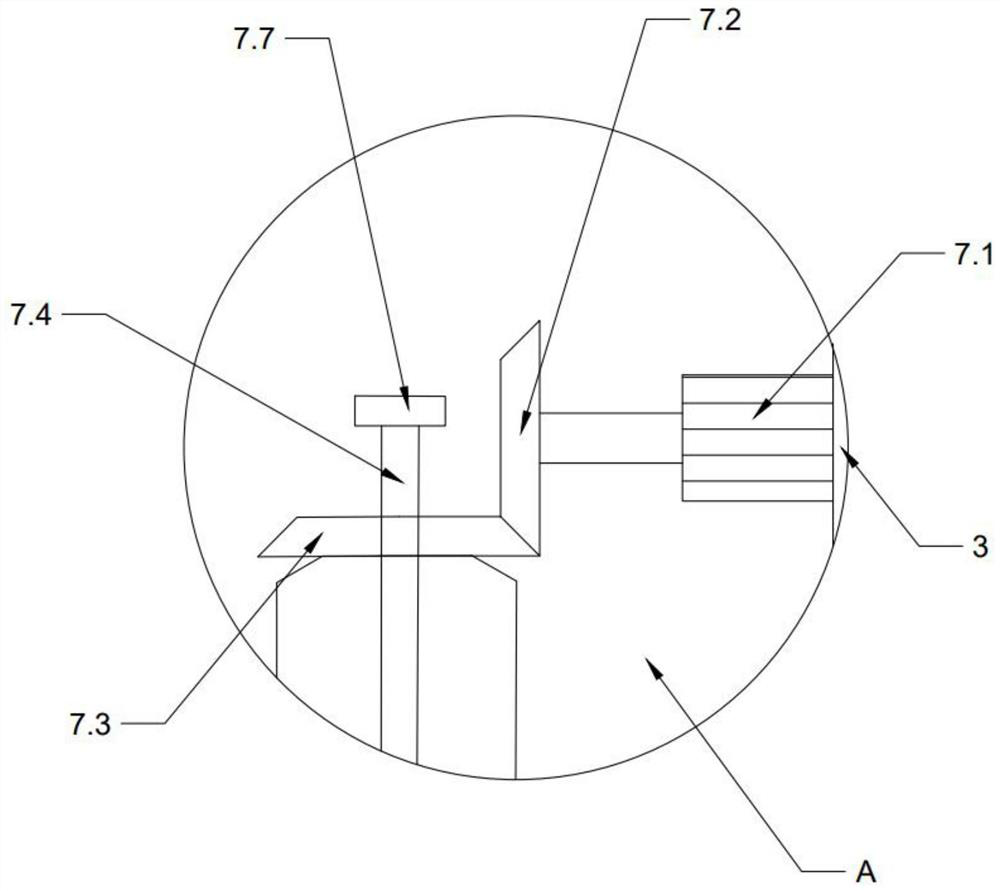

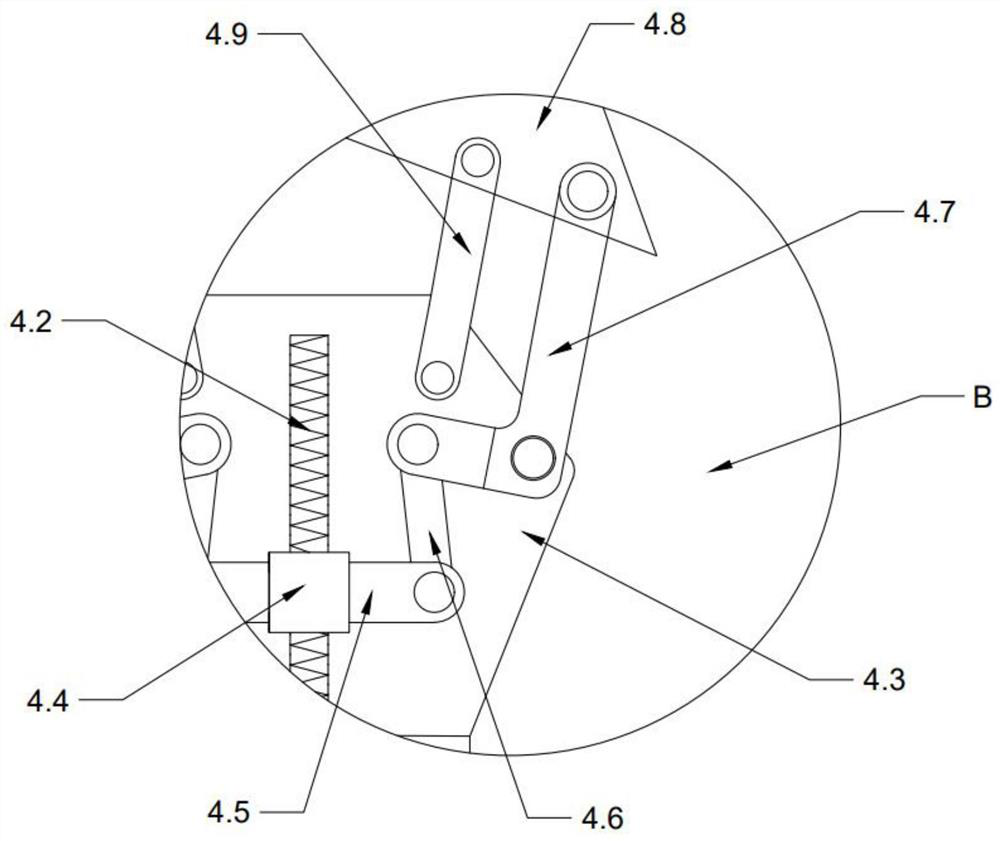

[0021] A metal surface heat treatment device, characterized in that it includes a bottom box 1, a plurality of movable casters 2 are arranged at the bottom of the bottom box 1, a treatment box 3 is arranged on the bottom box 1, and a grabbing box 3 is arranged inside the bottom box 1. Component 4, the grabbing component 4 includes a motor A4.1 arranged inside the bottom box 1, the output end of the motor A4.1 is provided with a threaded rod 4.2, and the inside of the processing box 3 is provided with a grabbing shell 4.3, The threaded rod 4.2 is arranged inside the grasping shell 4.3, the threaded rod 4.2 is provided with a sliding block 4.4, both sides of the sliding block 4.4 are provided with lugs 4.5, and one end of the lugs 4.5 is provided with a connecting rod A4 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap