Output control device and method for experiment of injecting high-temperature gas-phase solvent into thick oil

A control device and high-temperature gas technology, which is applied in the field of physical simulation experiments of heavy oil recovery, can solve the problems of frequent switching of gas flow and difficult operation, and achieve the effects of high pressure control accuracy, low pressure fluctuation range and flexible control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be described more clearly, and the preferred embodiments are further illustrated in connection with the preferred embodiments. Those skilled in the art will appreciate that the following description is illustrative and not limiting, and the scope of the invention should not be limited.

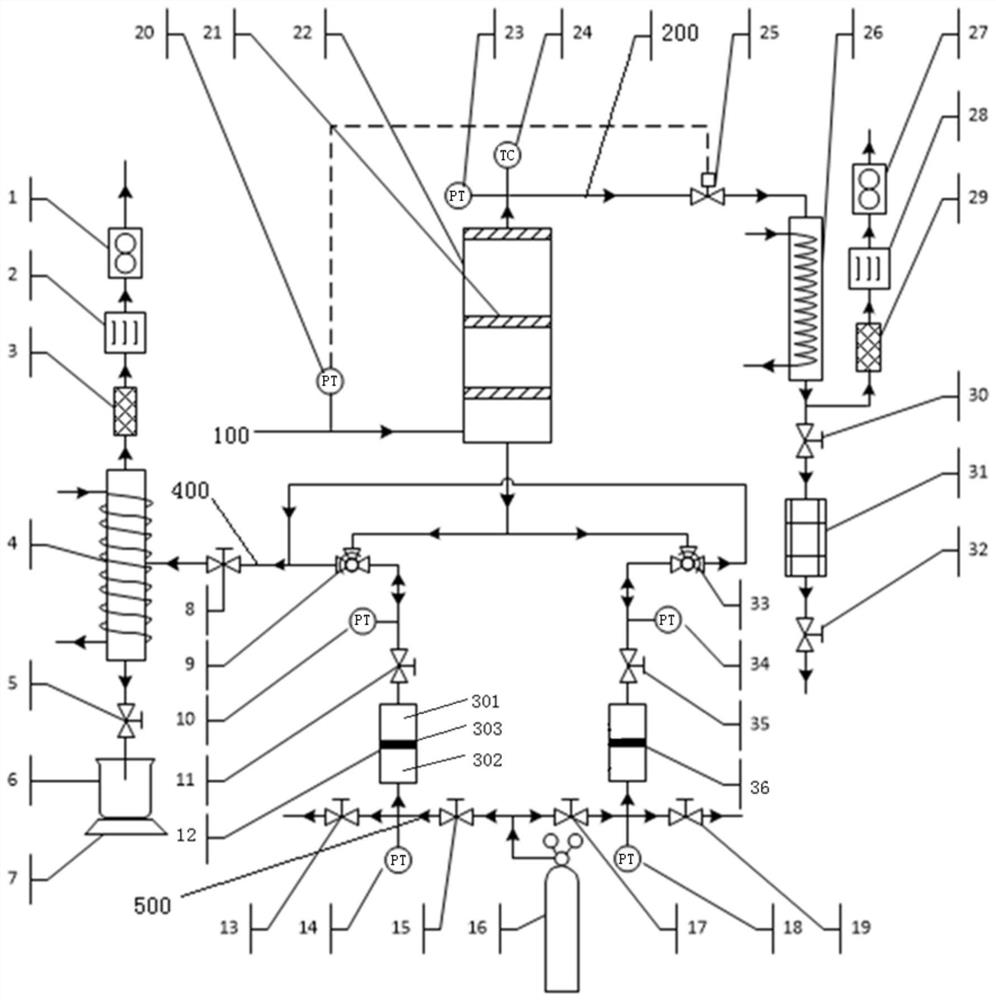

[0060] Such as figure 1 As shown, the present invention provides an output control device for a heavy oil injection high temperature gas phase solvent experiment, which comprises at least: a liquid pipeline 100, a first gas separator 22, a vent line 200, an automatic control. Acycle unit and intermediate container;

[0061] The tube line 100 is in communication with the feed port of the first gas separator 22, and the air opening of the first gas-liquid separator 22 is in communication with the vent line 200, the first gas liquid The liquid opening of the separator 22 is in communication with the intermediate container;

[0062] An automatic control pressure back ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com