Self-adaptive compensation type mechanical sealing device

A mechanical seal device, self-adaptive compensation technology, applied in the direction of engine seals, mechanical equipment, engine components, etc., can solve the problems of restricting the reliability and life of mechanical seals, permanent deformation, limited automatic compensation range, etc., to eliminate radial The effect of force component force, prolonging service life and automatic compensation interval increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

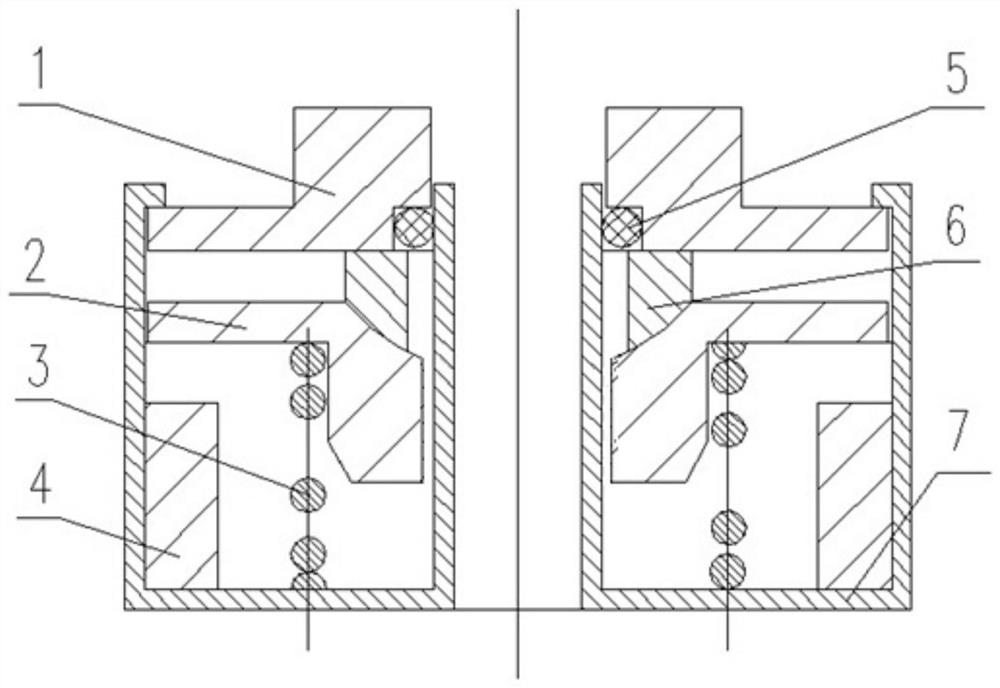

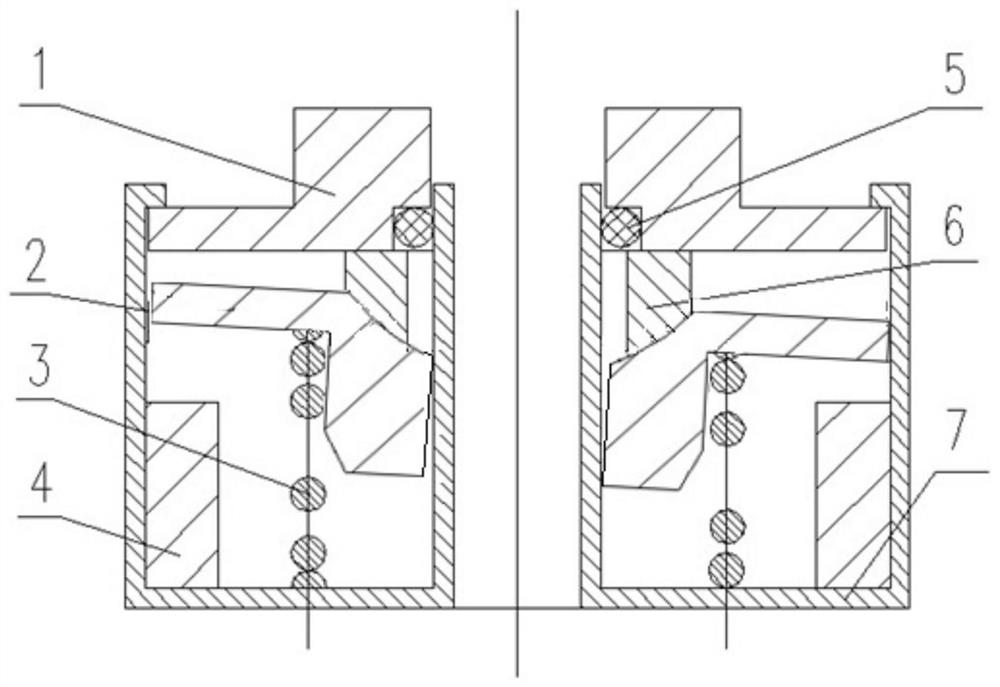

[0023] Embodiment 1 provides an adaptive compensation type mechanical seal device, including a graphite ring 1, a spring seat 2, a spring 3, a sealing ring 5, a spherical spacer 6 and a housing 7;

[0024] The spring seat 2, the spring 3, the seal ring 5 and the spherical spacer 6 are all located in the housing;

[0025] The housing is provided with a hollow guide column, and the graphite ring 1, the spring seat 2 and the spherical pad 6 are all set on the hollow guide column, and the end surface of the spring seat 2 is provided with a spherical arc surface ring groove; the spring seat There is a gap between the hollow guide post;

[0026] The spring is arranged between the spring seat and the housing, and provides elastic thrust;

[0027] The lower end surface of the spherical pad is a spherical arc torus, and the spherical arc torus is matched with the profile of the spherical arc surface ring groove, and the space between the spherical arc torus and the spherical arc surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com