Satellite-to-ground camera imaging system for direction measurement of optical remote sensing satellite

An optical remote sensing and imaging system technology, applied in the field of remote sensing satellite imaging, can solve the problems of difficult to guarantee pointing accuracy, complex mathematical models, and limited pointing solution accuracy, and achieves the effect of strong ease of use and improved surveying and mapping accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

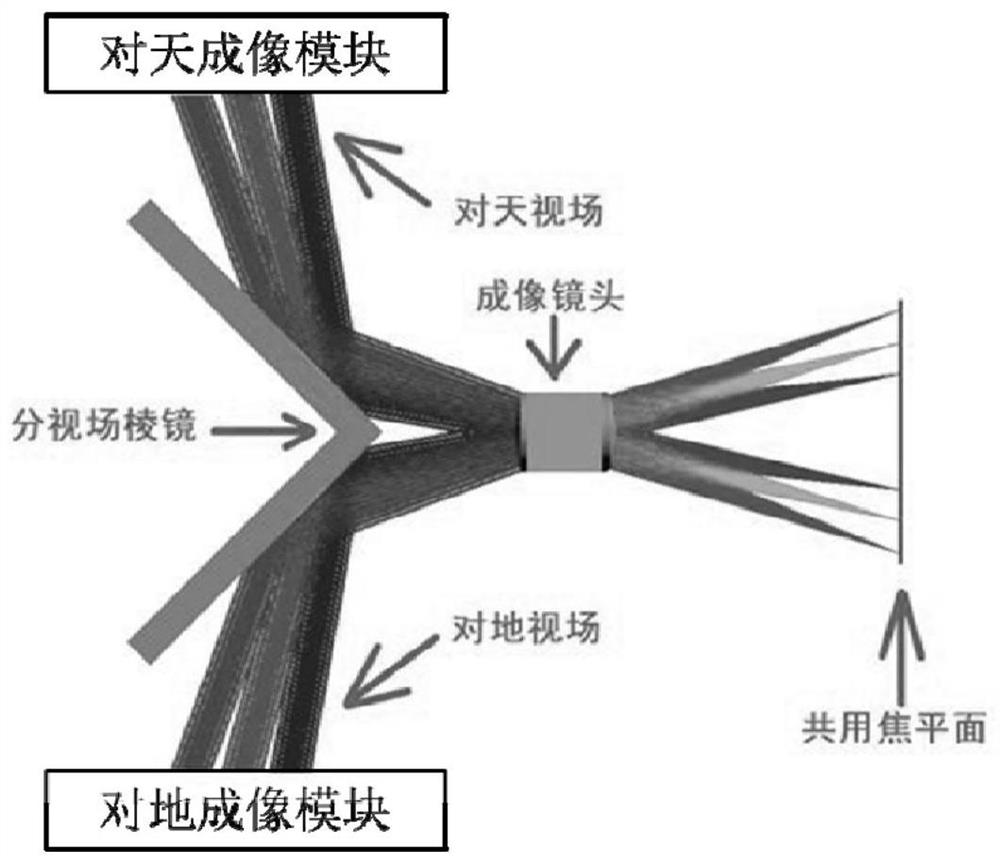

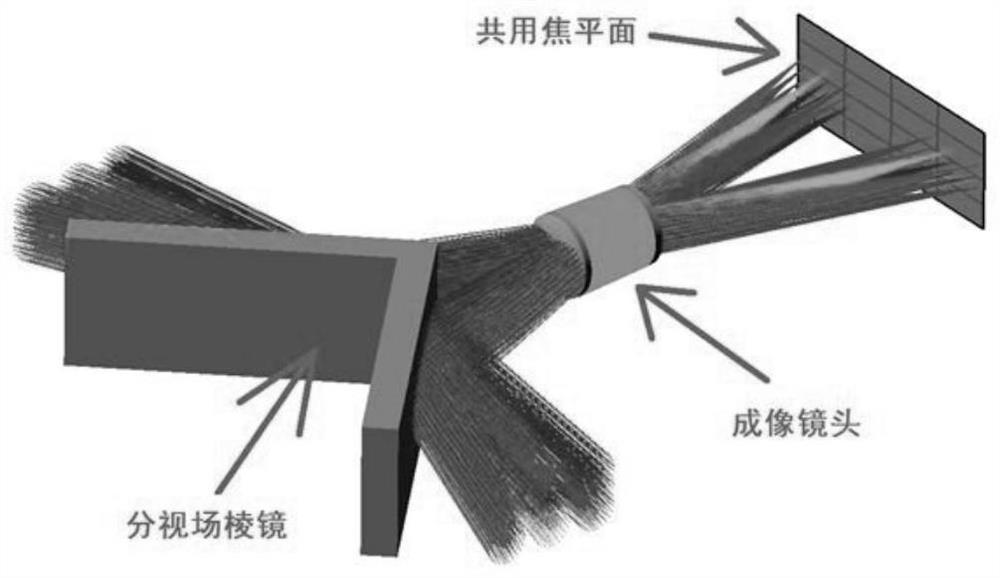

[0021] Such as figure 1 As shown, an imaging system for a star-earth camera includes a field-of-view prism, a shared imaging lens, a shared imaging detector and a processing module, and the field-of-view prism is formed by two angles, such as mutually perpendicular The reflective surface is formed, and the imaging detector is placed at the focal plane of the imaging lens. Functionally, the imaging system can be divided into a sky imaging module and an earth imaging module.

[0022] The sky imaging module is used for star imaging, and the light from the starry sky is reflected by one of the reflection surfaces of the field-of-view prism and enters the imaging lens. It should be noted that, in the field of view of the star-to-earth camera, the working principle of the star-to-sky imaging module is similar to that of the star camera or star sensor. They all use star imaging, pixel subdivision and high-precision attitude calculation, etc. Technology completes its orientation and...

Embodiment 2

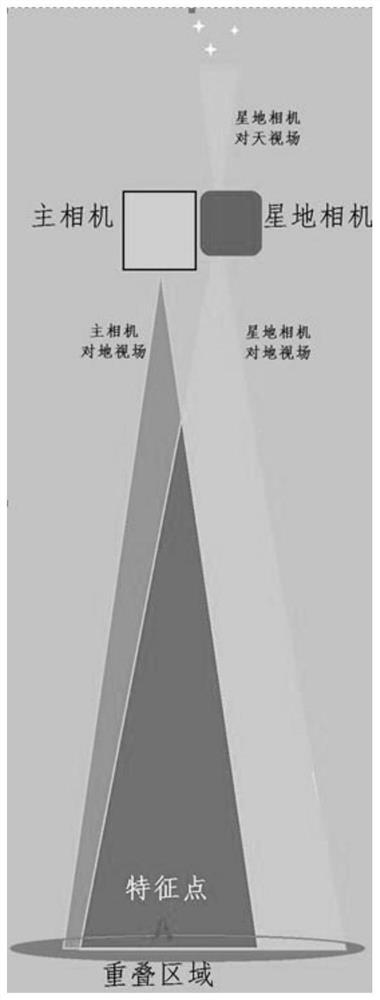

[0027] In order to ensure high-precision imaging and positioning of optical remote sensing satellites, it is necessary to solve the boresight pointing of optical remote sensing satellites with high precision. Based on the above embodiments, the satellite attitude determination and the main load boresight can be directly related through the optical imaging of the satellite-ground camera, so as to realize satellite Accurate measurement of attitude and principal load boresight. Its working principle is: the imaging lens of the star-ground camera passes through the front-end field of view beamsplitter prism to simultaneously image the starry sky and the ground, and the two images are imaged on the same focal plane; the image of the starry sky is used to calculate the satellite attitude data, and then calibrate The relationship between the field of view of the earth and the attitude of the satellite; there is an overlapping area between the field of view of the satellite-ground came...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com