Finish machining manufacturing data collector

A technology of data collector and micro control unit, which is applied in the direction of comprehensive factory control, comprehensive factory control, instruments, etc., can solve the problems of low efficiency and slow speed, and achieve the effect of quick installation, small appearance and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

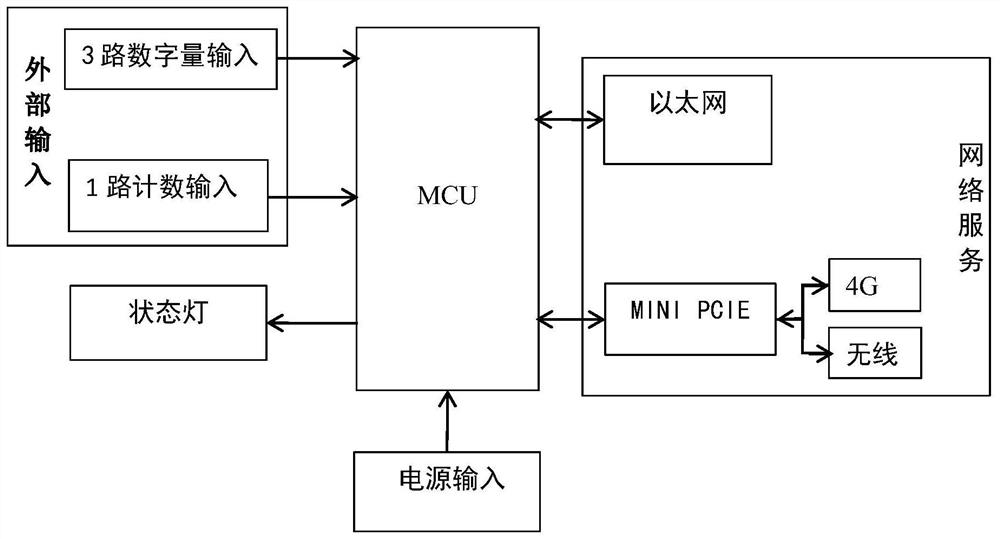

[0013] Such as figure 1 As shown, the present invention provides a data collector for finishing manufacturing, including an MCU micro-control unit, a digital input module, a counting input module, a power input module, an Ethernet module, a 4G network service module and a WIFI wireless network service module. The output terminals of the digital input module and the counting input module are all connected to the input terminal of the MCU micro control unit, the Ethernet module is bidirectionally connected with the MCU micro control unit, and the 4G network service module and the WIFI wireless network service module are connected to the The MCU micro control unit is bidirectionally connected, and the output end of the power input module is ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap