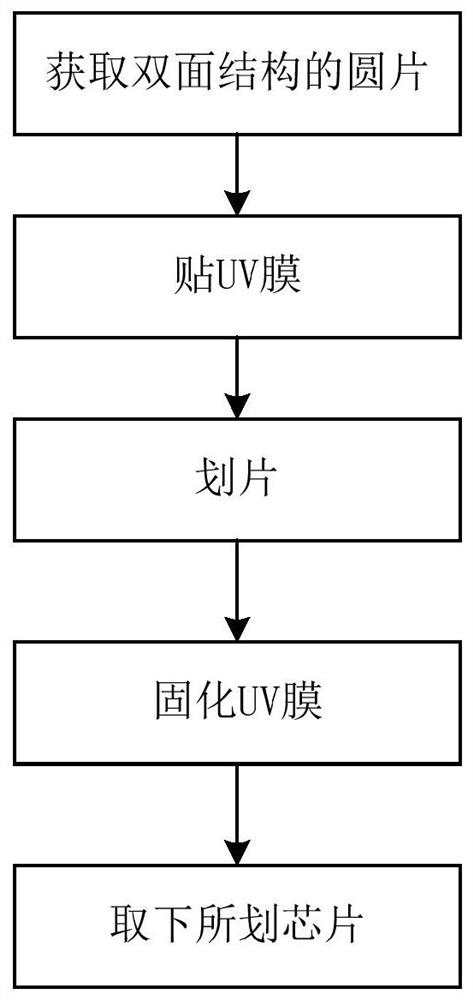

Scribing method of wafer with double-sided structure

A dicing and wafer technology, used in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as chip defects and yield reduction, and achieve the effect of improving yield and protecting structural surfaces.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

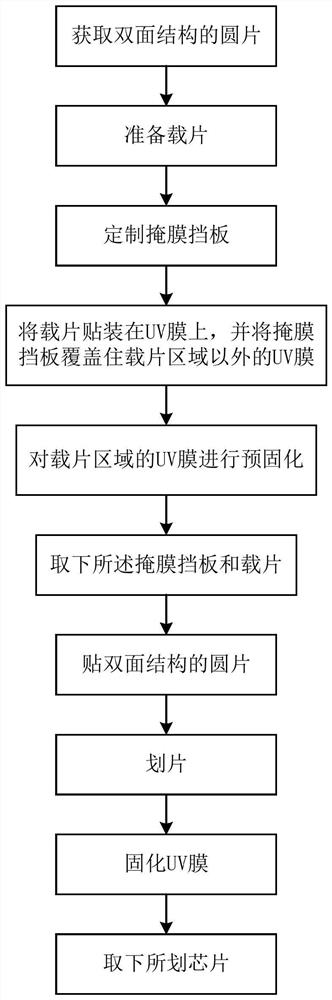

[0026] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

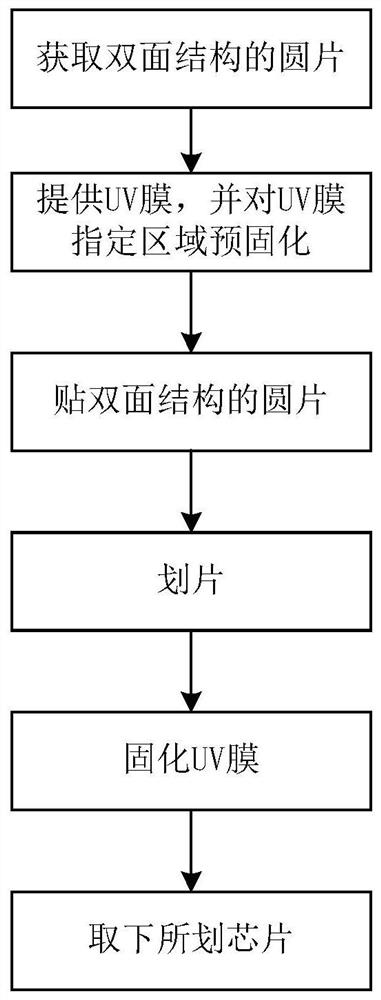

[0027] Embodiment 1 of the present invention discloses a method for dicing wafers with a double-sided structure. Please refer to figure 2 As shown in the flow chart, the scribing method of the present embodiment includes the following steps:

[0028] Obtain a wafer of double-sided structure;

[0029] Provide UV film and pre-cure the designated area of the UV film;

[0030] Attach one side of the wafer to the UV film so that the pre-cured designated area completely covers the chip area on the wafer;

[0031] Scribe the wafer attached with UV film to complete the separation between the chips on the wafer;

[0032] Perform secondary curing on the UV film and remove the chip.

[0033] Preferably, the pre-curing treatment is completed by irradiation with ultraviolet lamps, and the irradiation time of ultraviolet lamps is 20s to 40s.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com