High-performance wiring terminal strip

A terminal block, high-performance technology, applied in the direction of connection, conductive connection, clamping/spring connection, etc., can solve the problems that affect the accuracy of test data, the test probe has no stable force point, and the data stability is poor. To achieve the effect of improving convenience, ensuring reliability and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

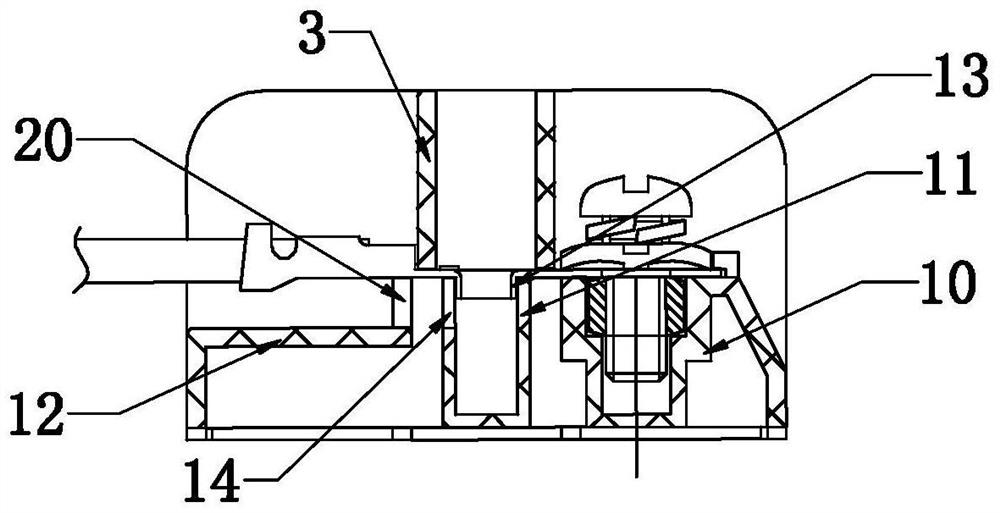

[0037]The high-performance wiring terminal block of this embodiment is illustrated by taking a single-phase wiring unit as an example. It includes an insulating base 1 and a metal conductive sheet 2 that can be placed in the insulating base for connecting wires. The base 1 includes a bottom plate and two side plates on the bottom plate, and a support spacer between the two side plates is provided on the base, wherein the support spacer can adopt an integrated multi-cavity structure or multiple Independent structure, said supporting spacer in the present embodiment is preferably a front fixed seat 10, an insulating shell 11 as a detection well and a rear support seat 12 arranged in the insulating base 1, through the front fixed seat 10, The insulating shell 11 and the rear support seat 12 can support the metal conductive sheet and divide the metal conductive sheet into three parts for isolation. Two transverse partitions 3 are also arranged between the two side plates of the ins...

Embodiment 2

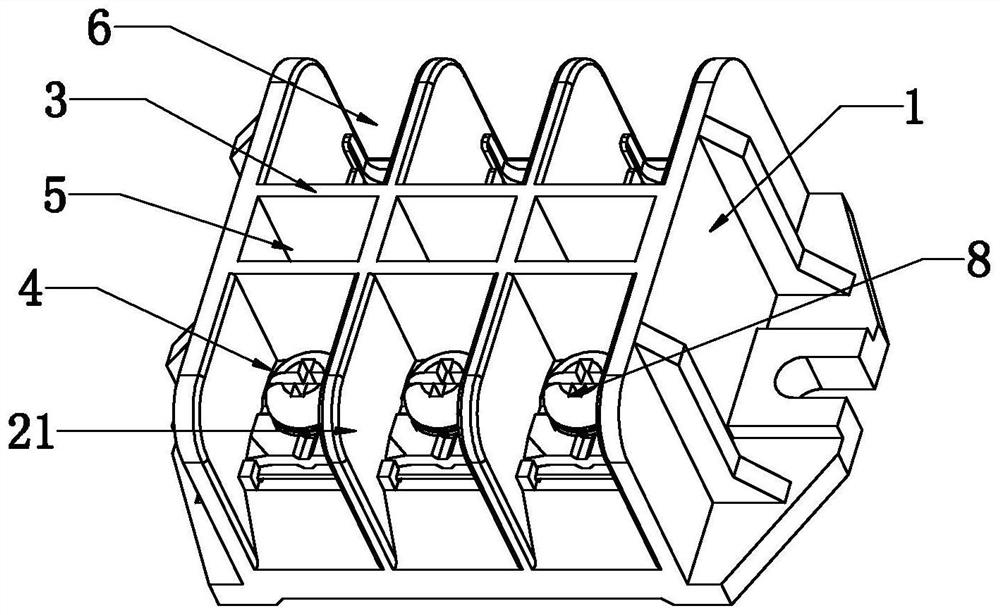

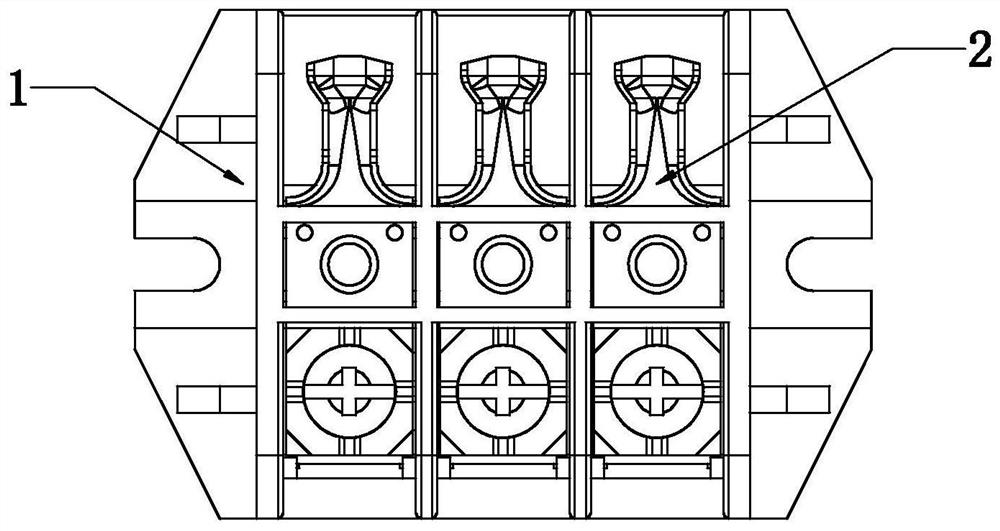

[0040] The high-performance terminal block of this embodiment is a kind of Figure 1-7 The terminal block of the three-phase connection unit shown in the figure can be seen from the figure that the high-performance terminal block of this embodiment is actually composed of multiple phase connection units assembled on the same insulating base, and the left and right sides of the insulating base The side is provided with a U-shaped groove ( figure 2 The direction shown), the specific structure of each single-phase wiring unit is the same as that of Embodiment 1, specifically, between the two side plates of the insulating base 1, there are two The longitudinal partition 21 vertically penetrates from the upper part of the insulating base (the top is flush with the transverse partition) to the bottom of the insulating base, so that three metal conductive sheets can be installed to form three wiring units, Depend on figure 2 It can be seen that two horizontal partitions and two v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com