Liquid accumulation prevention control method and device, compressor and air conditioning equipment

A control method and control device technology, applied to compressors, refrigerators, control systems, etc., can solve problems such as the inability to completely remove liquid accumulation inside the compressor, achieve the effects of increasing temperature, improving reliability, and avoiding liquid-filled startup

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

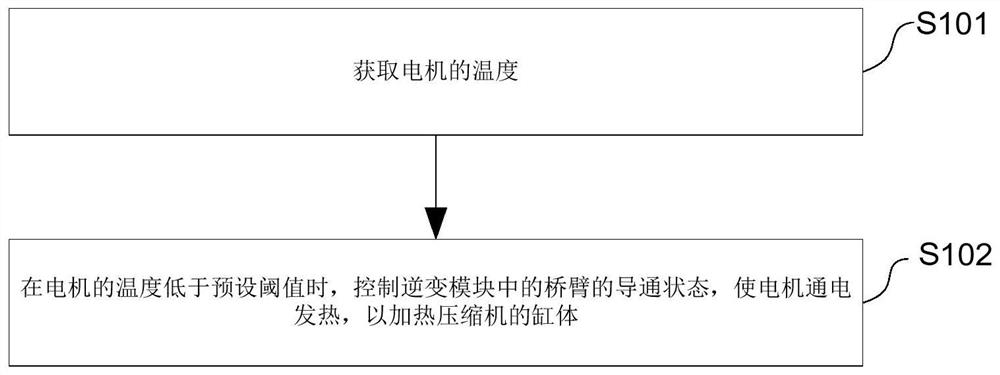

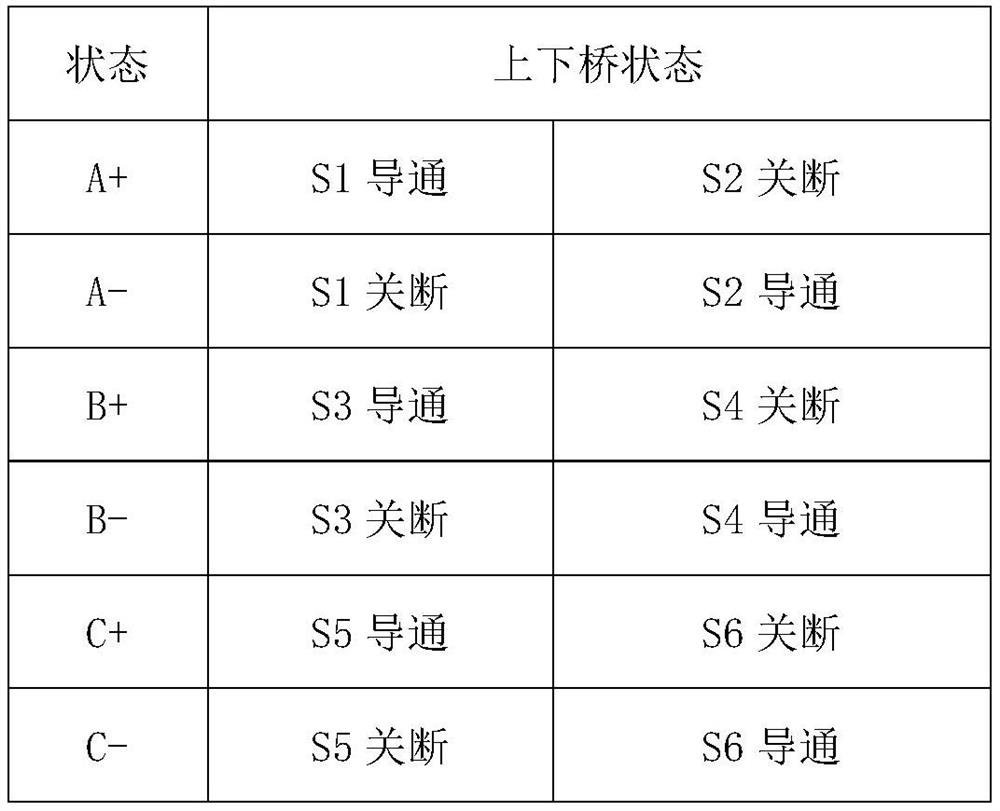

[0049] This embodiment provides a method of controlling the control method for the compressor, figure 1 For the structural diagram of the compressor according to an embodiment of the present invention, figure 1As shown, the compressor includes a rectifier module 1, inverter module 2, and motor 3, inverter module 2 including first inverse bridge, second inverse bridge, and three inverting bridges, wherein the first reverse The first upper bridge arm S1 and the first lower bridge arm S2, the first upper bridge arm S2, the first upper bridge arm S1 and the first lower bridge arm S2 are first phased in the first phase winding u, the second reverse The bridge includes the second phase winding V, third reverse of the line connecting motor 3 drawn between the second upper bridge S3 and the second lower bridge arm S4, the second upper bridge arm S4, the second upper bridge arm S3, and the second lower bridge arm S4. The third bridge arm S5 and the third lower bridge arm S6, the third uppe...

Embodiment 2

[0057] In this embodiment, another anti-volume liquid control method is provided. In order to implement the temperature of the motor, that is, the temperature of the cylinder block of the compressor is, including:

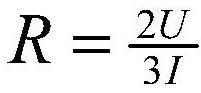

[0058] Control the inverter module input a pulse signal of the set frequency; the motor resistance value corresponding to the pulse signal of the set frequency is acquired, and then determine the temperature of the motor; wherein the motor resistance value varies with the frequency of the input pulse signal, and Preset the corresponding relationship between the temperature of the motor and the resistance value. The control inverter module inputs a pulse signal, including: controlling the target bridge arm in the inverter module to input the pulse signal; wherein the target bridge arm comprises at least two upper bridge arms and at least one lower bridge arm. If the inverter module inputs a pulse signal having a set frequency, the motor resistance value corresponding to...

Embodiment 3

[0083] This embodiment provides a contrast control device, applied to a compressor, the compressor chart above mentioned above. figure 1 As shown in, including the rectifier module 1, inverter module 2, and motor 3, Figure 4 For the structural diagram of the anti-gas solution control device according to an embodiment of the present invention, Figure 4 As shown, the apparatus includes:

[0084] Get module 10 for obtaining the temperature of the motor.

[0085] When the temperature of the motor can be achieved, the temperature of the motor, that is, the temperature of the motor, that is, the temperature of the compressor is determined according to the mechanical resistance value and the temperature of the motor, that is, the temperature of the compressor is determined according to the relationship between the motor resistance value and the temperature.

[0086] The control module 20 is configured to control the on-state of the bridge arm in the inverter module to heat the motor to h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com