Method for producing thermal infrared sensor array in vacuum-filled wafer-level housing

A sensor array, wafer-level technology, applied in the direction of electric solid-state devices, semiconductor devices, instruments, etc., can solve the problems of large lateral overall size and difficult to accommodate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

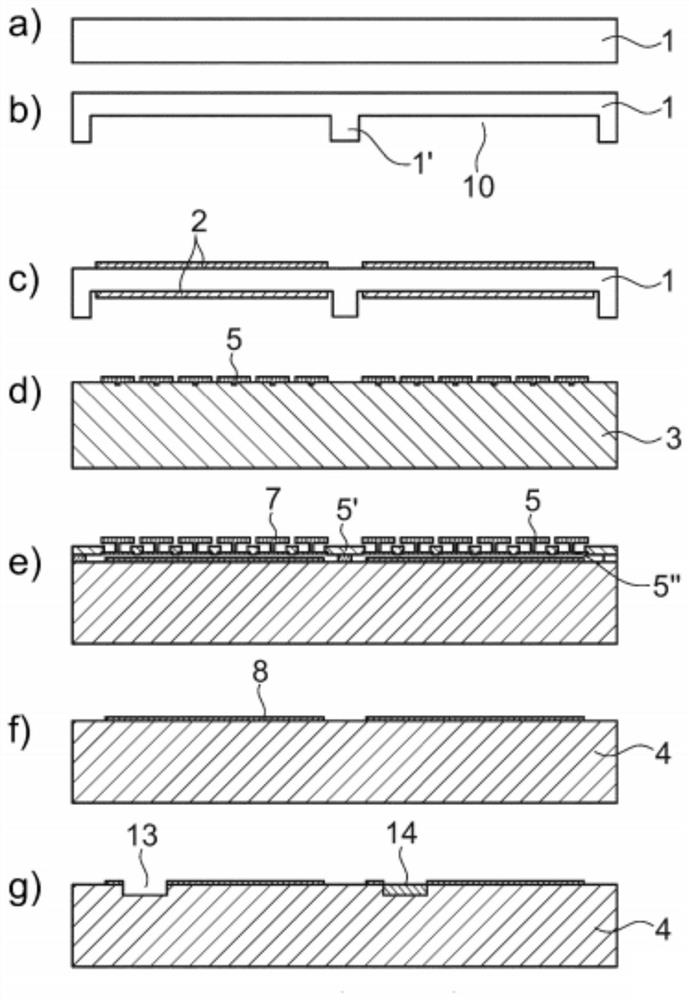

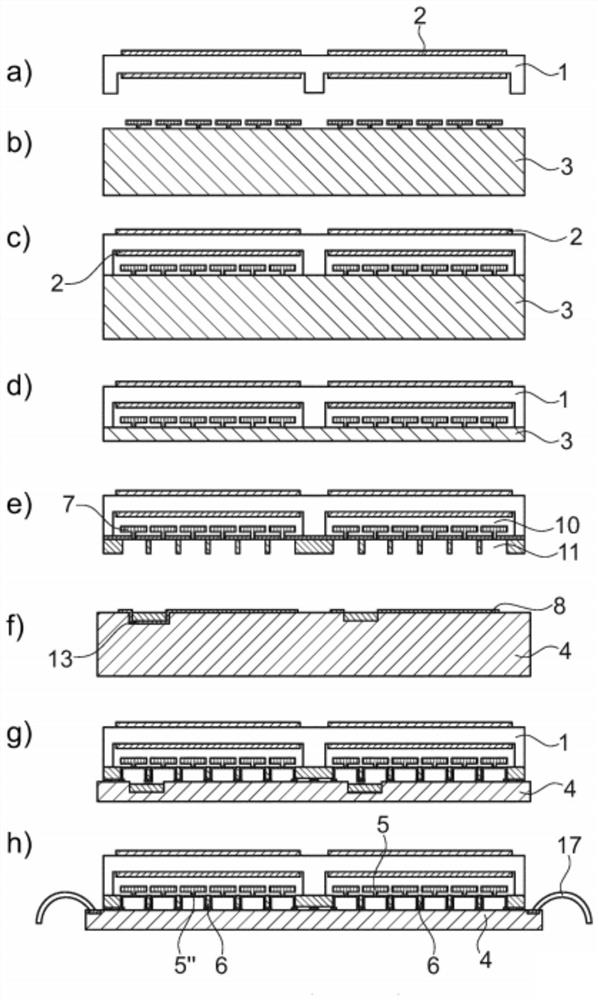

[0066] It will be appreciated that only the details of various wafers are respectively shown in Figures 1 through 9, in fact, the area of these wafers is much larger, and each of which includes a plurality of as described adjacent to each other. These structures are manufactured. Single is monolithized by dividing into a separate thermal infrared sensor array.

[0067] FIG. 1 shows a basic structure of a very thin infrared sensor array in a vacuum wafer level package before the respective wafer mounting but prior to single sheet, which has an upper cover wafer 1, thinned central wafer 3 and bottom wafer 4 . In the lid wafer 1, there is a cavity 10 above a set of sensor pixels 5.

[0068] According to Figure 1, the infrared sensor array includes a plurality of groups of infrared sensor arrays having a plurality of sensor pixels 5, a narrow strip 5 ', and a cavity 10, wherein the plurality of sensor pixels 5 are adjacent to each other or four or more. The group rules are arranged,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com