Discharging equipment for injection molding and processing technology

A technology of injection molding and injection molding equipment, which is applied in the field of unloading equipment and processing technology for injection molding, and can solve the problems of users' health impact, inconvenient use, and high surface temperature of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

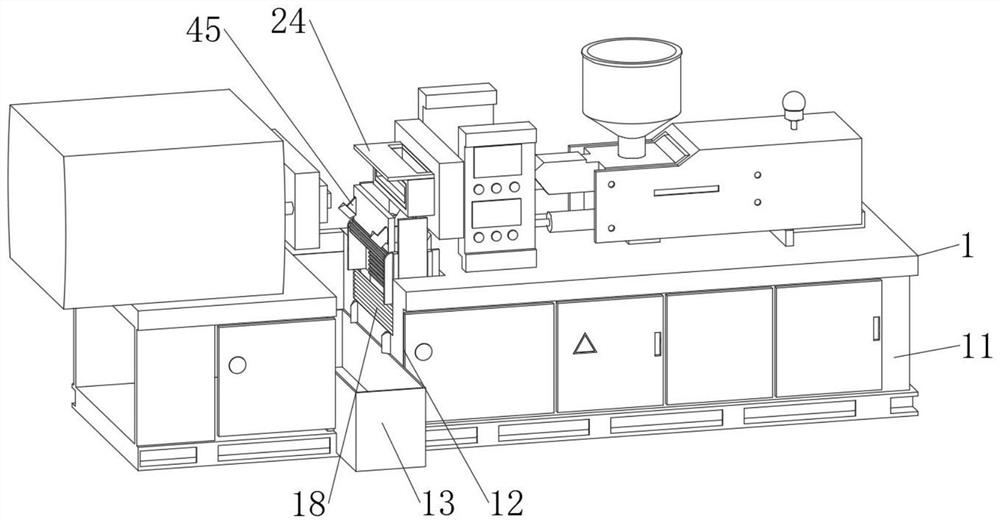

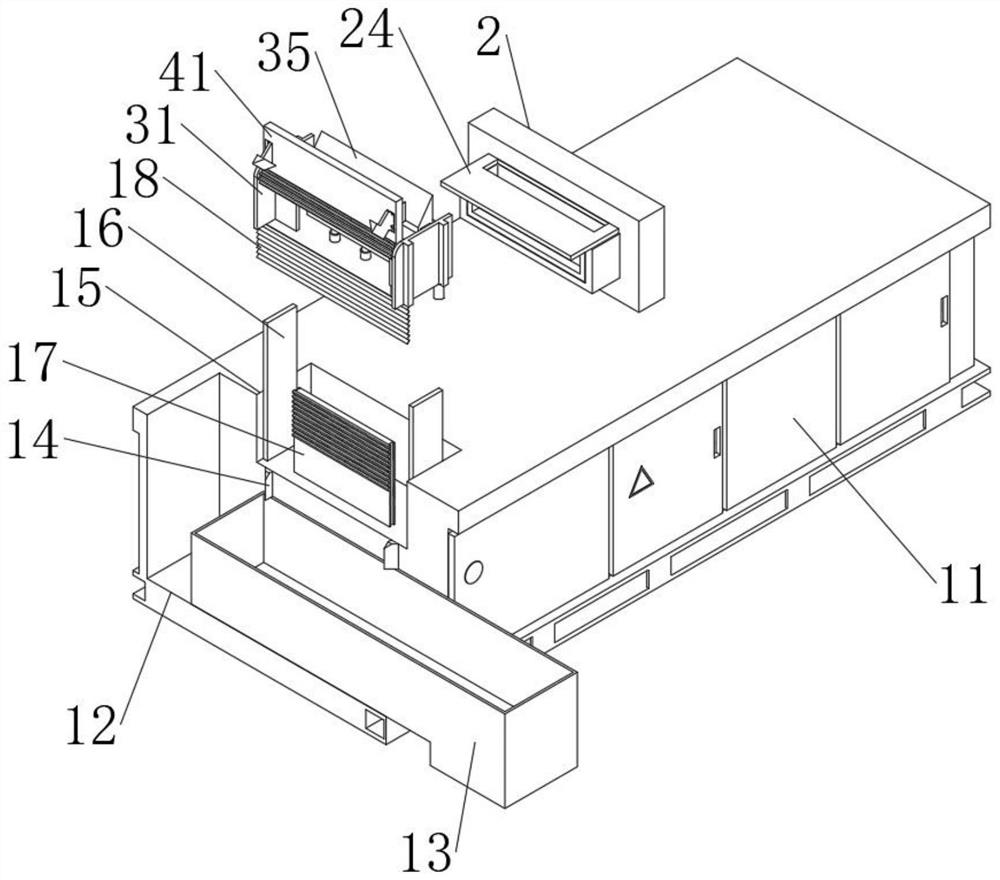

[0036] see Figure 1-8 , an embodiment provided by the present invention: a kind of unloading equipment for injection molding, comprising:

[0037] The cylinder used in this application is a product that can be purchased directly on the market, and its principle and connection mode are all prior art well known to those skilled in the art, so they will not be repeated here.

[0038] The injection molding equipment body 1, the injection molding equipment body 1 includes a body 11, the top surface of the body 11 is provided with a storage tank 12, the inside of the storage tank 12 is slidably installed with a water tank 13, and the inner wall of the storage tank 12 is fixedly installed. A movable groove 15 is provided on the side wall of 12, a guide plate 16 is fixedly installed on the inner wall of the movable groove 15, and a rack plate 17 and a blind 18 are fixedly installed on the bottom wall of the movable groove 15;

[0039] Stripping structure 2, stripping structure 2 com...

Embodiment 2

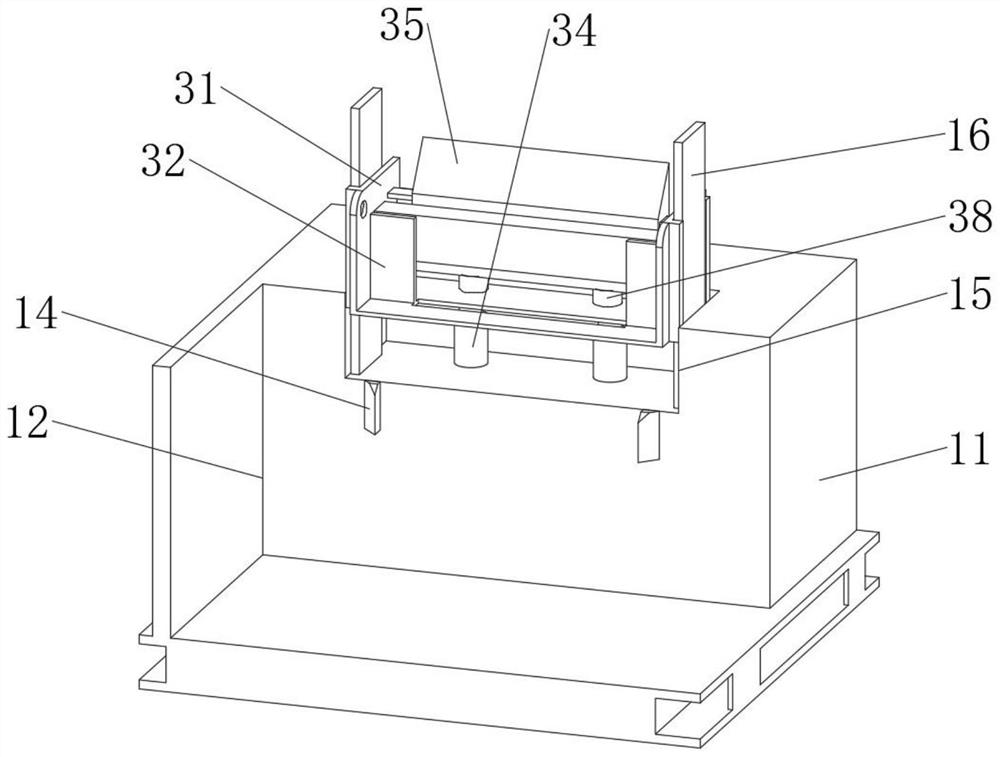

[0049] On the basis of Embodiment 1, after parting the mold, start the first cylinder 34, the first cylinder 34 will lift the cover 31 upwards, which can drive the cover 31 to move upwards on the outside of the rack plate 17, and the cover 31 will drive the gear cylinder 41 and The rack plate 17 is engaged, and the material guide plate 42 rotates around the gear cylinder 41, so that the gear cylinder 41 tends to be vertical, and after the first cylinder 34 is lifted, the material guide plate 42 is located on the left side of the product 28, and then the second cylinder is started. Two cylinders 38, the second cylinder 38 lifts the inserting plate 35 upwards, the top of the inserting plate 35 is inserted into the movable cavity 23, contacts with the top plate 26, and pushes the top plate 26, and the top plate 26 drives the push plate 25 to move inside the mold cavity 22 , the product 28 inside the mold cavity 22 can be ejected to the left, the product 28 is in contact with the f...

Embodiment 3

[0052] The present invention also provides a kind of unloading process for injection molding, the specific steps are as follows:

[0053] S1: Start the first cylinder 34, the first cylinder 34 lifts the outer cover 31 upwards, the outer cover 31 drives the gear cylinder 41 to mesh with the rack plate 17, the material guide plate 42 rotates around the gear cylinder 41, and rises with the outer cover 31 to guide the material The plate 42 is kept parallel to the mold 21 and is located on the right left side of the product 28;

[0054] S2: start the second cylinder 38, the second cylinder 38 lifts the inserting plate 35 upwards, inserting the inserting plate 35 upwards into the inside of the movable chamber 23, pushes the top plate 26, the top plate 26 drives the push plate 25 to move to the left, and pushes the push plate 25 The product 28 is pushed out from the mold cavity 22, and the product 28 is stuck between two sets of fixed claws 44;

[0055] S3: The second cylinder 38 re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com