Full-automatic production equipment for notebook packaging box

A technology for production equipment and packaging boxes, applied in the field of fully automatic production equipment for notebook packaging boxes, can solve the problems of poor processing continuity, processing, and poor adaptation of production equipment, and achieve the effect of ensuring sufficient supply and improving processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions in the embodiments of the present invention will be apparent from the drawings in the embodiment of the present invention.

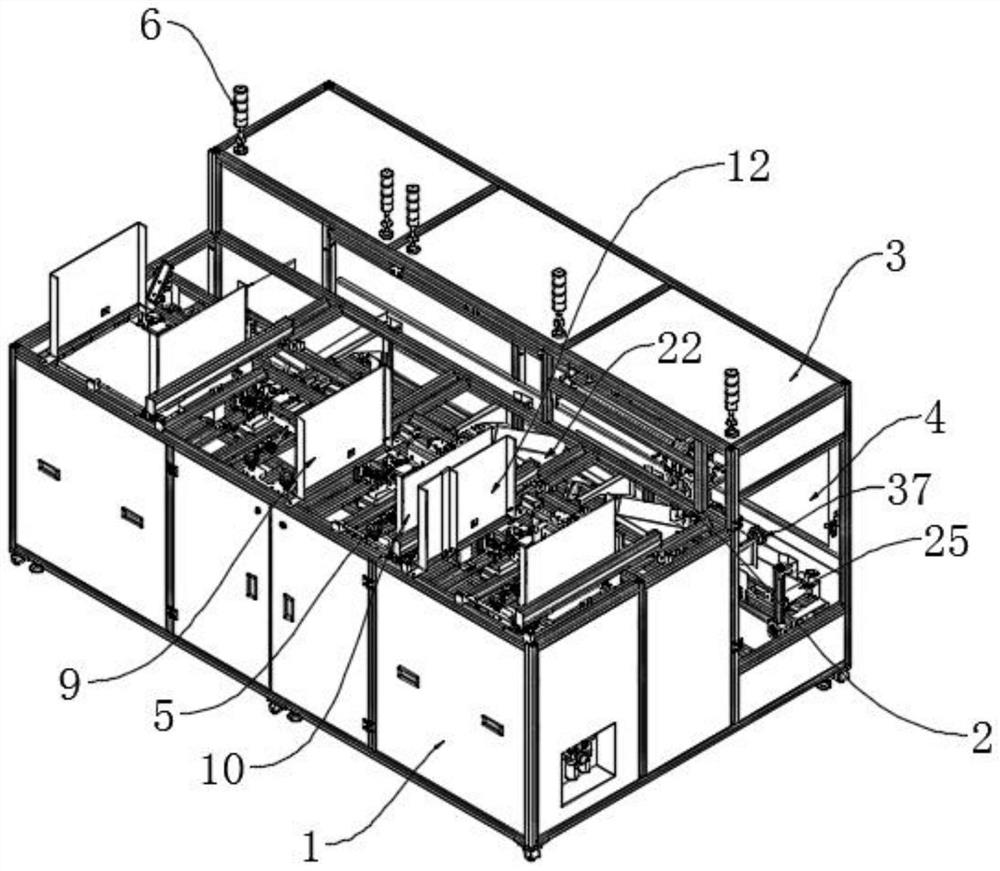

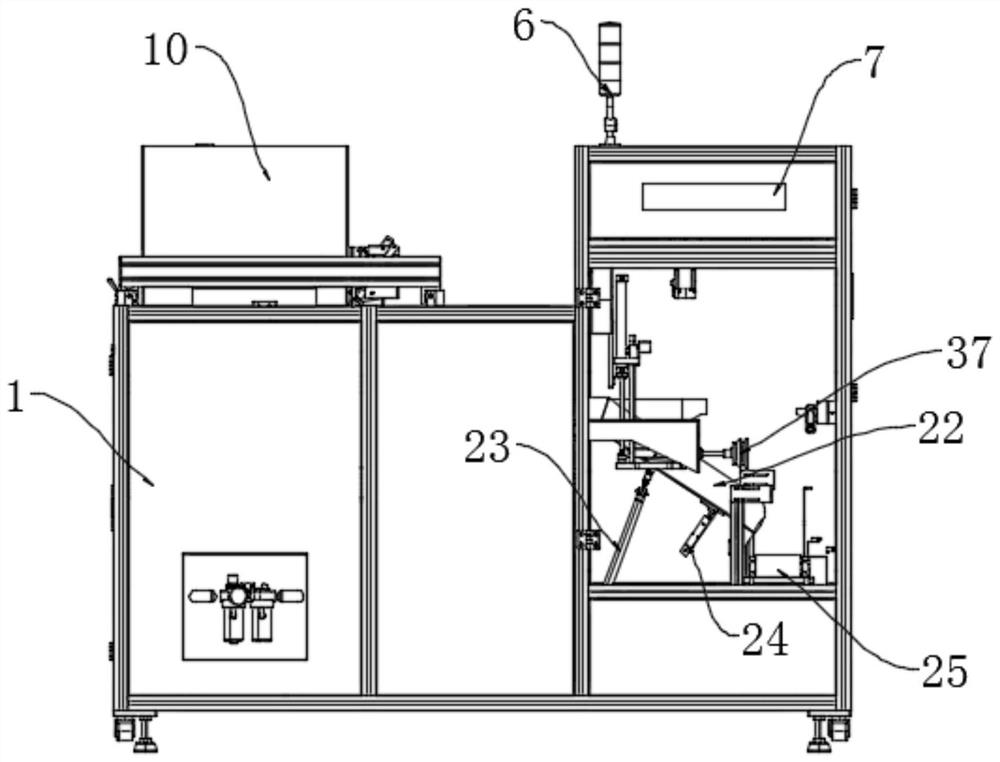

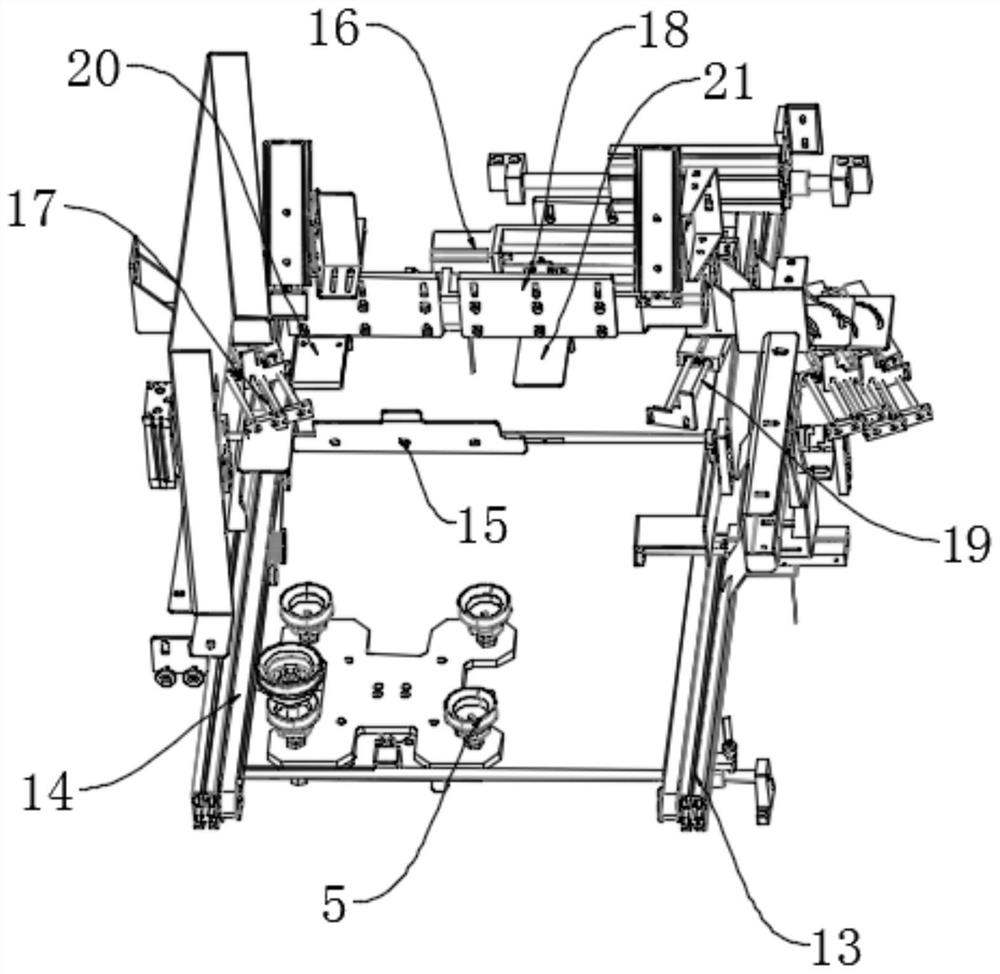

[0028] See Figure 1-7 The present invention provides a technical solution: notebook packaging box with automatic production equipment, including rack 1, multi-set silo components, multi-set folding box assemblies, multi-group transplanting unit 2, conveying assembly, shield 3, and sheets Port 4, the frame 1 is in a rectangular structure, the shroud 3 being mounted on the upper surface side of the frame 1, the silo member, and is distributed in front of the rack 1, the folding box assembly mounting On the rack 1 and located on the silo component side, the transplanting unit 2 is distributed over the upper surface of the frame 1 and is located on the side of the silo component, and the transplanting unit 2 outputs the end facing the folding box assembly. The conveying assembly is mounted outside the end of the rack 1, and the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com