Goods shelf with high space utilization rate, goods shelf group and warehousing method

A high-space, high-utilization technology, applied in the field of mechanical structures, can solve problems such as difficult maintenance, high cost, and difficulty in popularization and application, and achieve the effects of improving work efficiency, ensuring stability, and reducing space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

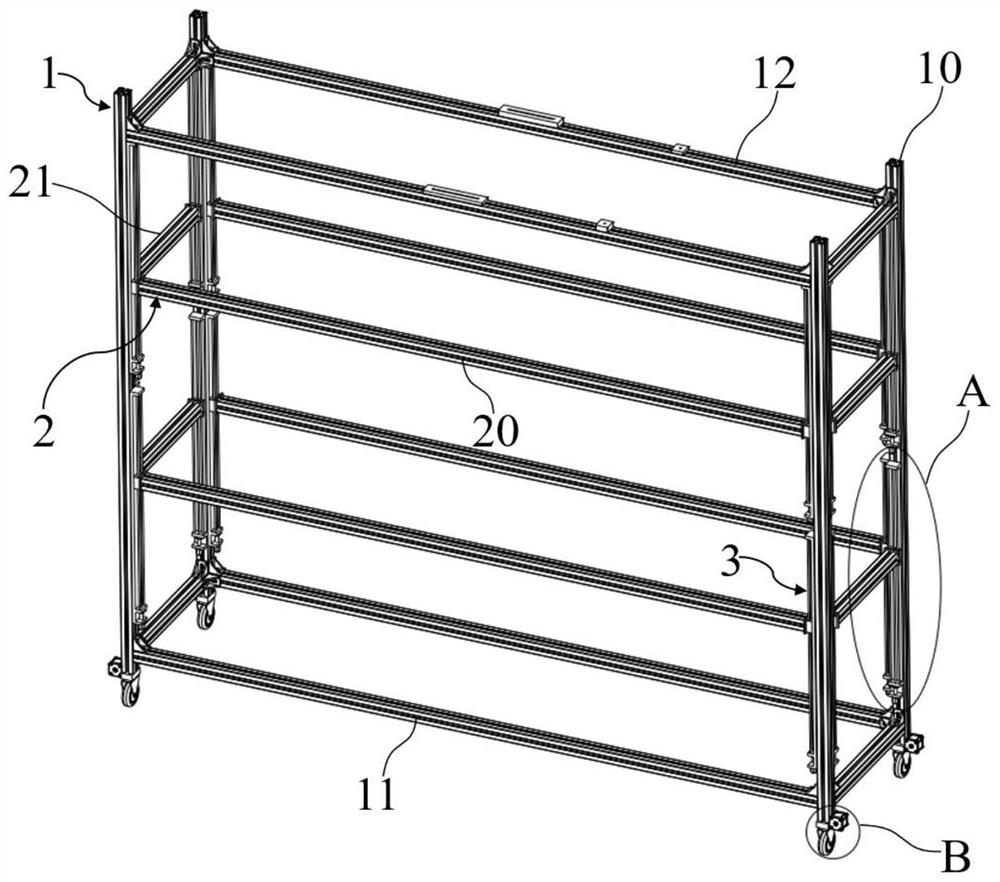

[0068] The shelf with high space utilization rate of this embodiment includes,

[0069] Shelf main body 1, it comprises column 10, bottom shelf 11 and top floor shelf 12; Described column 10 has four, all vertically arranged; Described bottom shelf 11 is rectangular, and four corners are fixedly connected with each column 10 bottoms respectively; The top frame 12 is rectangular, and the four corners are respectively fixedly connected with the tops of the columns 10;

[0070] Also includes:

[0071] There are several mobile shelves 2, which are all horizontally movably connected to the column 10 between the bottom shelf 11 and the top shelf 12;

[0072] Lifting drive unit 3, which drives the mobile shelf 2 to perform lifting motion.

[0073] Such as figure 1 As shown, in the shelf main body 1 of the present embodiment, four steel columns 10 are vertically arranged, and are respectively located at four corner points of a rectangle. Composed of two long beams and two short be...

Embodiment 2

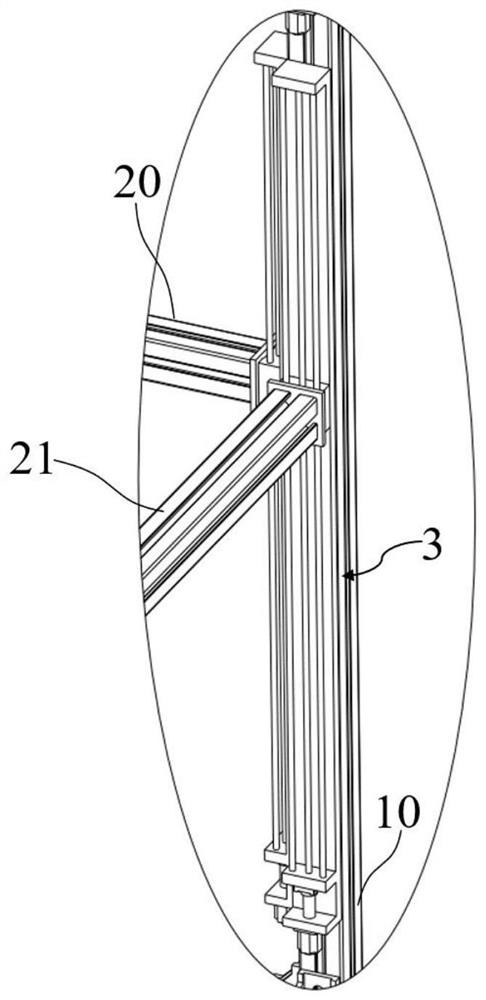

[0080] The shelf with high space utilization rate of this embodiment is further improved on the basis of Embodiment 1, and the lifting drive unit 3 includes:

[0081] Mounting seat 30, which is vertically installed on the column 10;

[0082] Screw rod 31, which is vertically arranged on the mounting base 30, and the two ends of the screw rod 31 are connected to the mounting base 30 in rotation;

[0083] The driving part 32 is fixedly installed on one end of the mounting base 30, and the output end of the driving part 32 is connected to the end of the screw rod 31 in transmission;

[0084] The slider 33 is sleeved on the screw rod 31 and is in transmission connection with the screw rod 31 , and the moving shelf 2 is in transmission connection with the slider 33 .

[0085] Such as figure 2 and image 3 As shown, the length direction of the mounting base 30 is arranged along the length direction of the column 10, the two ends of the mounting base 30 protrude from the vertical...

Embodiment 3

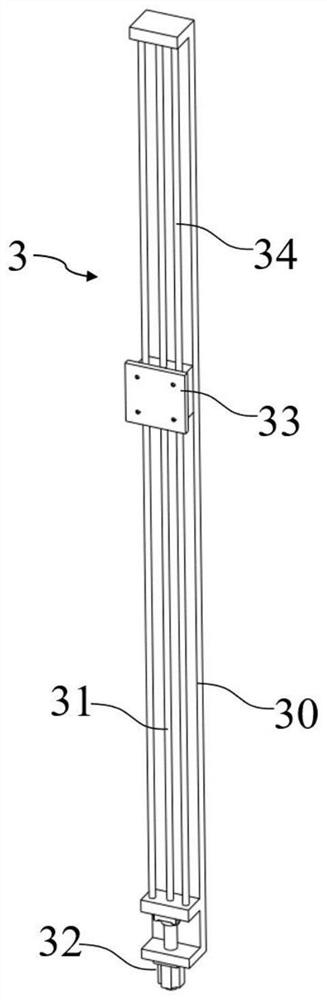

[0088] The shelf with high space utilization rate of this embodiment is further improved on the basis of Embodiment 2, and the lifting drive unit 3 also includes:

[0089] The guide rod 34 is parallel to the screw rod 31 and is vertically arranged on the mounting seat 30 and is located beside the screw rod 31 . The slider 33 is sleeved on the guide rod 34 .

[0090] Such as image 3 As shown, the lifting drive unit 3 of this embodiment is provided with two guide rods 34, which are arranged on both sides of the screw rod 31, and are all arranged in parallel with the screw rod 31. The two ends of the guide rods 34 are connected to the end plates of the mounting base 30. , the middle transmission of the slider 33 is sleeved on the screw rod 31, and the two ends of the slider 33 are respectively sleeved on the two guide rods 34, thereby ensuring that the slider 33 can move stably along a straight line during the transmission of the screw rod 31, Then ensure the stability and reli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com