Production equipment for wire-wound screen pipes with various gap diameters

A technology of wire-wound screen and production equipment, which is applied in the direction of conveying filamentous materials, thin material handling, transportation and packaging, etc., can solve the problems of inconvenient spacing adjustment, lack of diameter control components, and inconvenience in wire-wound screen production, etc. Achieve the effect of improving quality, improving use effect, and facilitating winding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

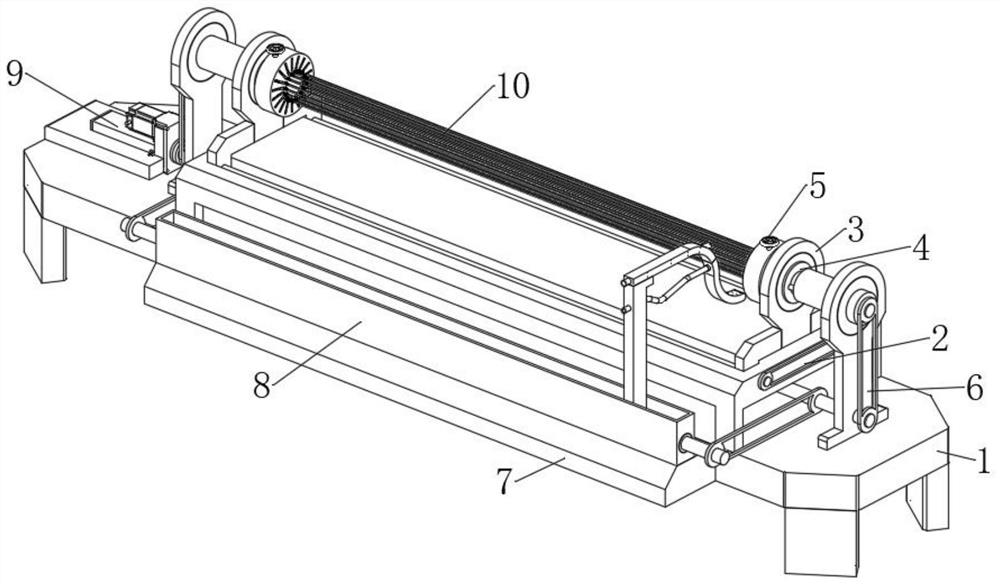

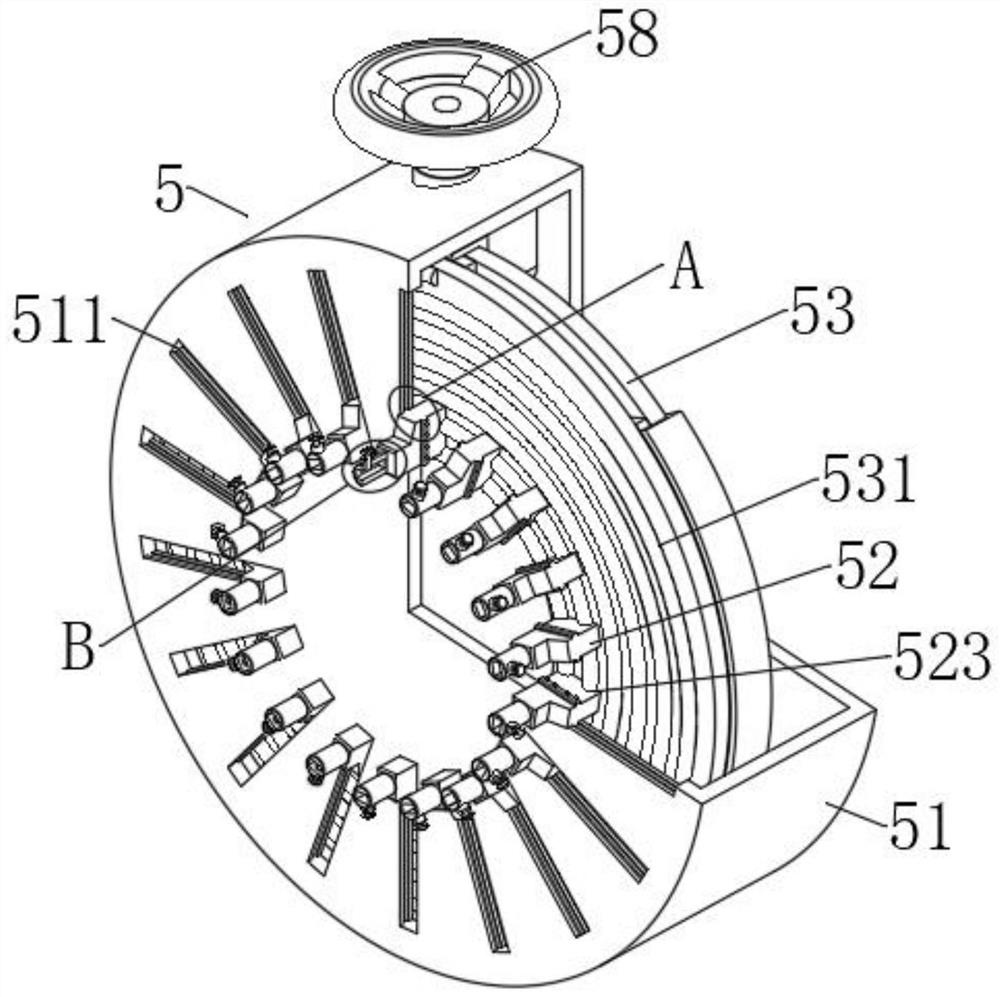

[0032] Example: such as Figure 1-Figure 10 As shown, the present invention provides a wire-wrapped screen production equipment with various slit diameters. Two support frames 3 are symmetrically distributed, the top of the support frame 3 is installed with a rotating seat 4 through bearing rotation, the opposite side of the rotating seat 4 is fixedly installed with a diameter control assembly 5, and the diameter control assembly 5 is provided with an annular array. A plurality of screen tube support bars 10 are distributed, the top of the bottom frame 1 is fixedly installed with a driving assembly 6 used in conjunction with the rotating seat 4, one side of the bottom frame 1 is fixedly installed with a bottom plate 7, and the top of the bottom plate 7 is fixedly installed with a thinning assembly 8. A driving motor 9 is fixedly mounted on the top side of the chassis 1 .

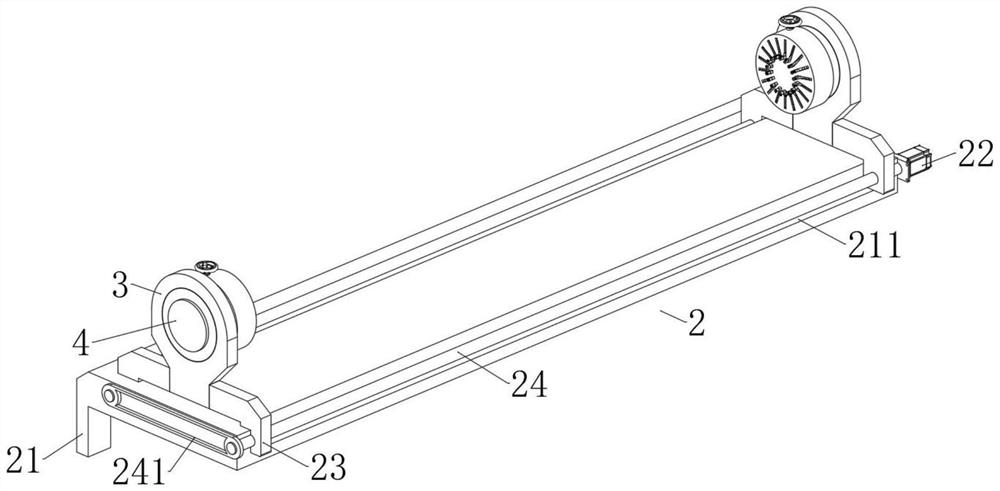

[0033] The distance adjustment assembly 2 comprises a distance adjustment bottom frame 21, the distance ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com