Coating device

A coating device and ruler technology, which is applied in sputtering coating, ion implantation coating, vacuum evaporation coating, etc., can solve the problems of difficult stripping, time-consuming and laborious, and low efficiency, and achieve improved measurement accuracy, simple process, and high efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The drawings illustrate embodiments of the disclosure and it is to be understood that the disclosed embodiments are merely examples of the disclosure, which may be embodied in various forms and therefore specific details disclosed herein should not be construed as limiting. , but merely as a basis for the claims and as a representative basis for teaching one of ordinary skill in the art to variously employ the present disclosure.

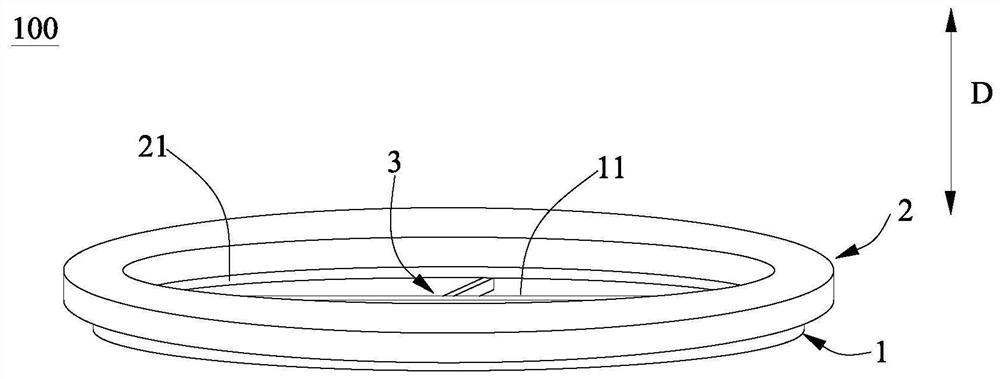

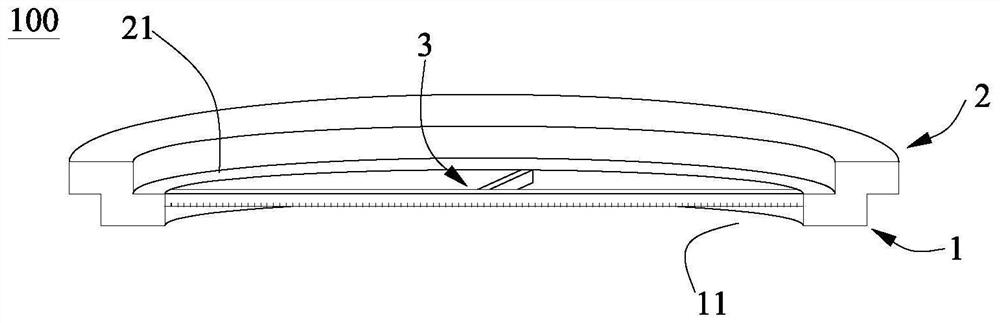

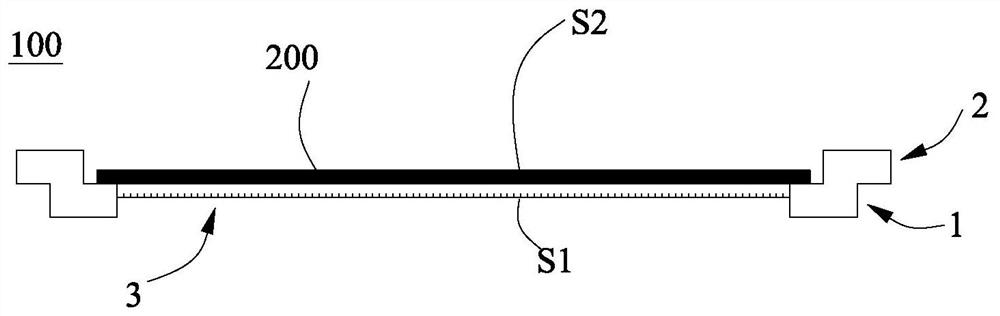

[0043] refer to Figure 1 to Figure 7 , the coating device 100 includes a first ring body 1, a second ring body 2 and a cross-shaped scale 3.

[0044] The first ring body 1 has a through hole 11 penetrating through the first ring body 1 along the thickness direction D of the first ring body 1 .

[0045] When viewed along the thickness direction D of the first ring body 1 , the cross-shaped scale 3 is centrally arranged in the through hole 11 . The cross-shaped scale 3 has a central origin portion 31, a first positive-axis scale portion 32, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com