Measurement Method of Center Thickness of Bilateral Displacement Differential Confocal Lens

A differential confocal and lens center technology, which is applied in the non-contact high-precision measurement of lens center thickness, and in the field of bilateral misalignment differential confocal lens center thickness measurement, can solve the problem of complex system structure, assembly process, and large errors. problems, to achieve the effect of improving the focus sensitivity and signal-to-noise ratio, improving the focus precision, and improving the measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

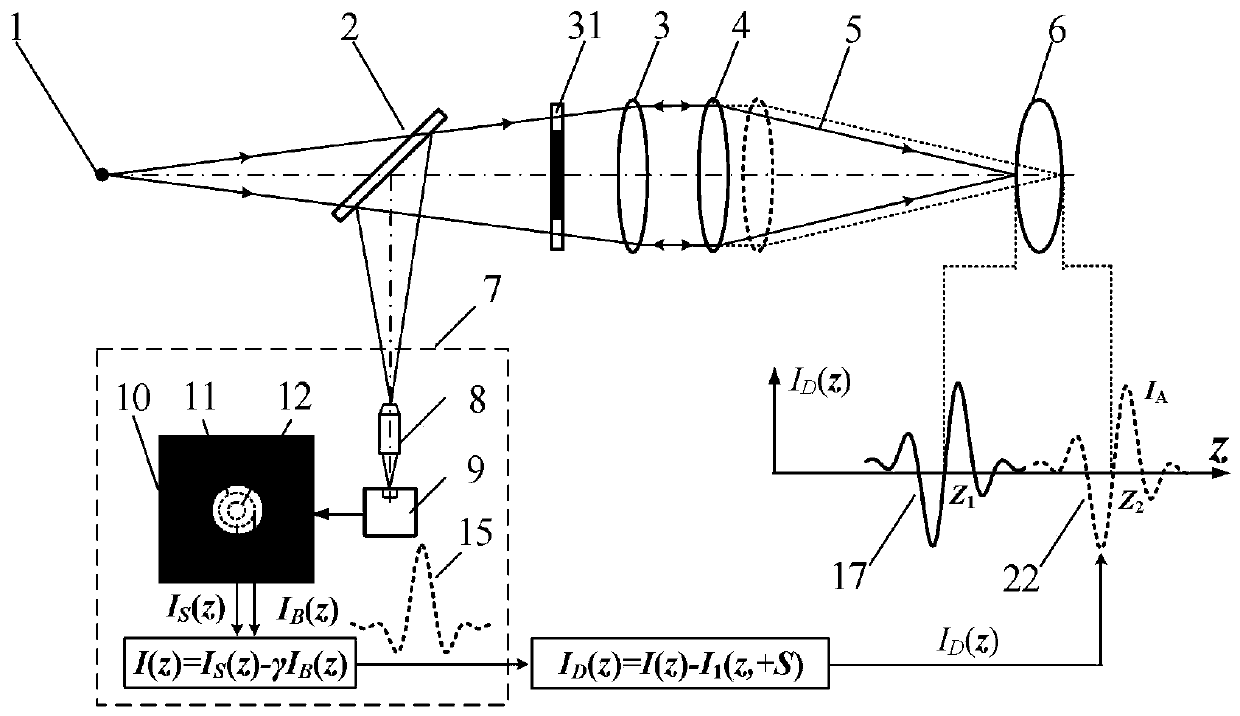

[0051] as attached Figure 6 As shown, the measurement steps of the method for measuring the central thickness of the bilateral misalignment differential confocal lens disclosed in this embodiment are:

[0052] a) Start the measurement software of the main control computer 24, turn on the laser 28, and the light emitted by the laser 28 passes through the microscope objective lens 29 and the pinhole 30 to form a point light source 1.

[0053] b) Adjust the measured lens 6 so that it has the same optical axis as the measuring objective lens 4 and the collimating lens 3, and the light emitted by the point light source 1 is converged into the measuring beam 5 after passing through the beam splitter 2, the collimating lens 3 and the measuring objective lens 4 On the vertex A of the measured lens 6, the measurement beam 5 reflected by the vertex A of the measured lens 6 passes through the measurement objective lens 4 and the collimator lens 3, and then is reflected by the beam split...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com