Efficient Hastelloy alloy star-shaped heat exchange equipment

A high-efficiency Hastelloy, heat exchange equipment technology, applied in heat exchange equipment, lighting and heating equipment, heat exchanger types, etc., to achieve sufficient heat exchange, increase heat exchange area, and reduce pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

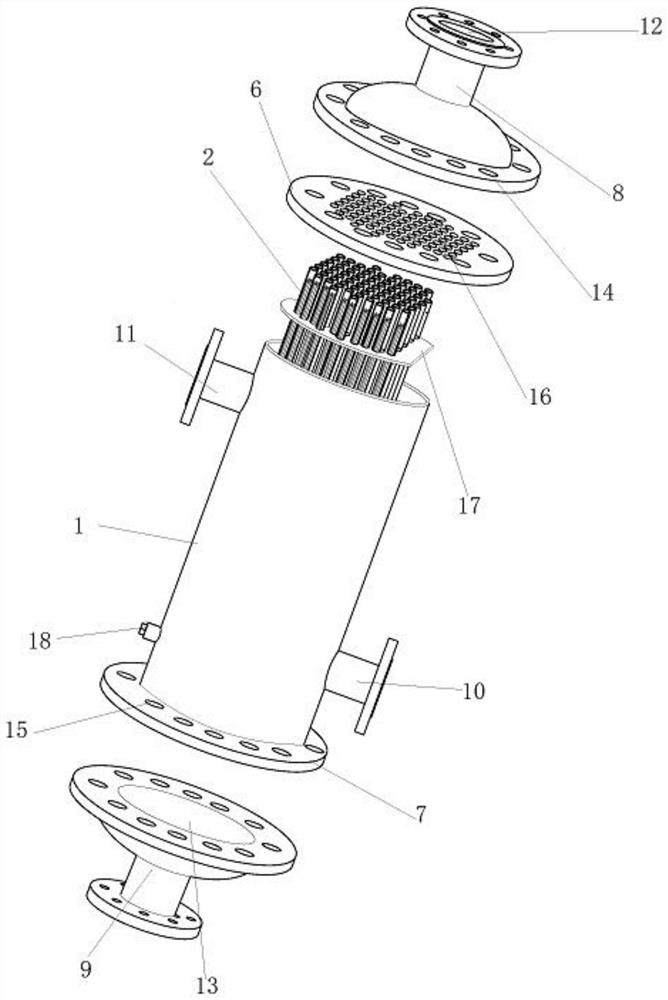

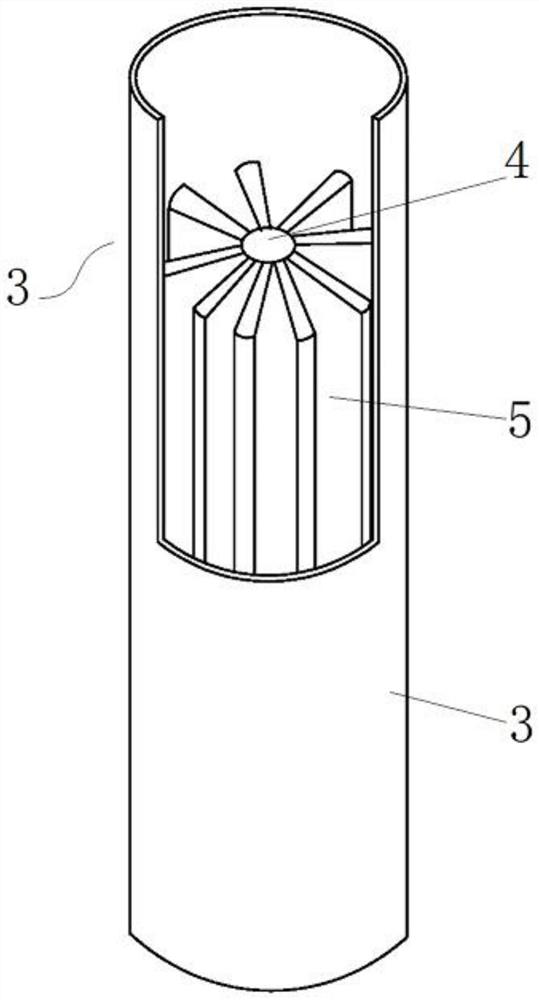

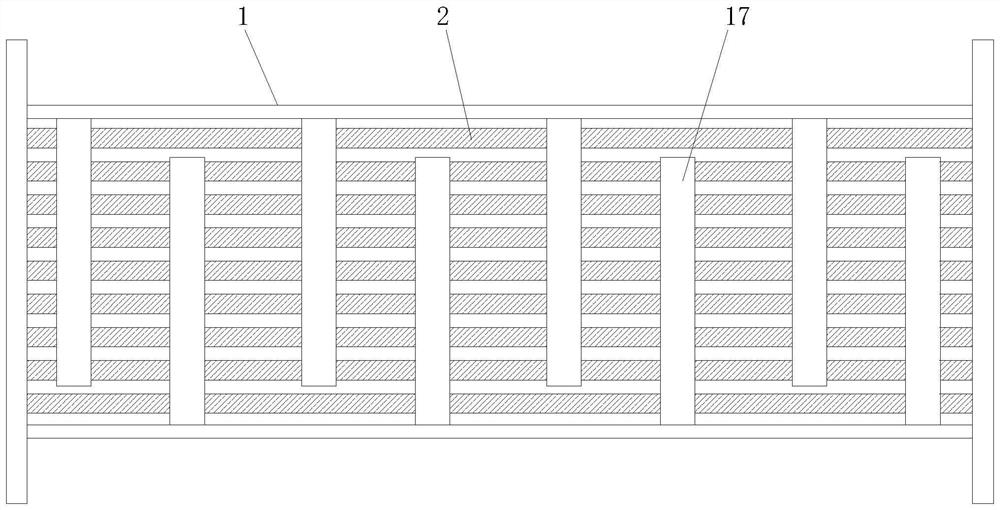

[0024] according to figure 1 , 2 As shown, this embodiment proposes a high-efficiency Hastelloy star-shaped heat exchange device, including a heat exchanger shell 1 and a heat exchange assembly 2, and the heat exchange assembly 2 is arranged on the heat exchanger shell 1 Inside, multiple sets of heat exchange components 2 are arranged at equal intervals along the height direction of the heat exchanger shell 1. The heat exchange components 2 include heat exchange tubes 3 and star-shaped fins, and the star-shaped fins It is arranged inside the heat exchange tube 3, and the star-shaped cooling fins include a central axis 4 and a cooling fin 5. The cooling fins 5 are arranged on the outside of the central axis 4, and the cooling fins 5 are set at equal angles with the central axis 4 as the center of the circle. There are multiple groups;

[0025] The upper and lower ends of the heat exchanger shell 1 are respectively provided with a first fixed tube plate 6 and a second fixed tu...

Embodiment 2

[0031] according to figure 1 , 2 , 3, this embodiment proposes a high-efficiency Hastelloy star-shaped heat exchange equipment, including a heat exchanger shell 1 and a heat exchange assembly 2, and the heat exchange assembly 2 is arranged in the heat exchanger shell 1, and multiple groups of heat exchange components 2 are equidistantly arranged along the height direction of the heat exchanger shell 1. The heat exchange components 2 include heat exchange tubes 3 and star-shaped fins, and the star-shaped The cooling fins are arranged inside the heat exchange tube 3, and the star-shaped cooling fins include the central axis 4 and the cooling fins 5. There are multiple sets of corners;

[0032] The upper and lower ends of the heat exchanger shell 1 are respectively provided with a first fixed tube plate 6 and a second fixed tube plate 7, and the first fixed tube plate 6 is equipped with an air inlet pipe 8, and the second fixed tube plate 7 An exhaust pipe 9 is installed on it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com