Correction method for improving high-temperature strain measurement precision

A high-temperature strain and measurement accuracy technology, used in measurement devices, force/torque/work instrument calibration/testing, instruments, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

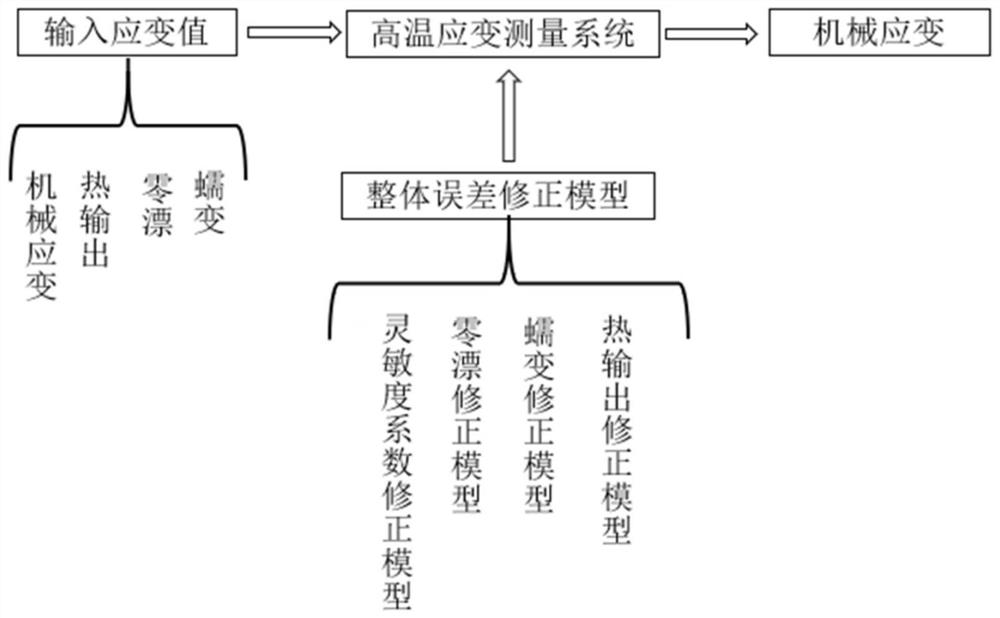

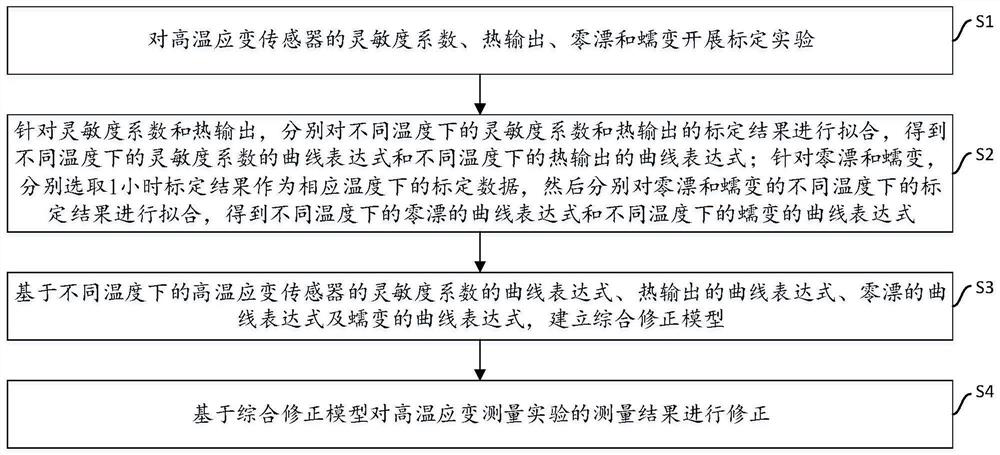

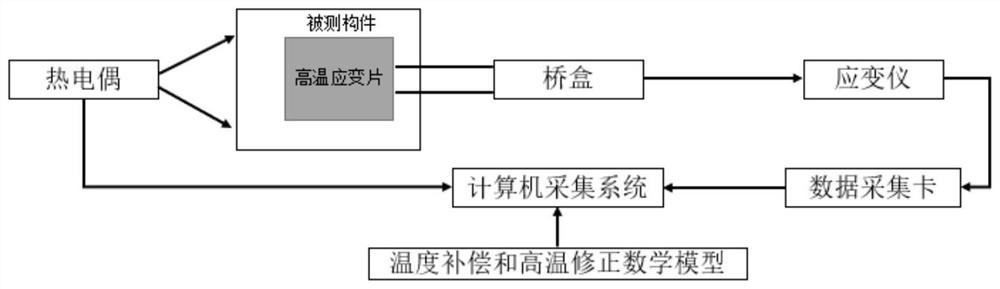

[0028] This embodiment provides a correction method for improving the accuracy of high-temperature strain measurement, which is used to eliminate the influence of temperature in the process of high-temperature strain measurement, obtain real strain, and realize thermal-mechanical decoupling. The implementation principle of this method is as follows figure 1 As shown, its execution flow is as follows figure 2 shown, including the following steps:

[0029] S1, Carry out calibration experiments on the sensitivity coefficient, heat output, zero drift and creep of high temperature strain sensors;

[0030] S2, for the sensitivity coefficient and heat output, respectively fit the calibration results of the sensitivity coefficient and heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com