A design method of fuel supply filling rate for aero-engine start-up

An aero-engine and design method technology, applied in complex mathematical operations, geometric CAD, special data processing applications, etc., can solve problems such as compressor stall, ignition failure, etc., to reduce stall, improve the success rate of starting ignition, and ensure consistency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the purpose, technical solution and advantages of the application more clear, the technical solution in the embodiment of the application will be described in more detail below in conjunction with the drawings in the embodiment of the application.

[0020] A method for designing the filling rate of starting fuel supply for an aero-engine. This application adopts the method of ensuring the consistency of ignition performance in the starting process to solve the problem of compressor stall or ignition failure during starting fuel supply.

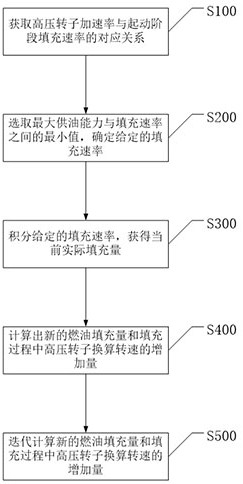

[0021] Such as figure 1 shown, including the following steps:

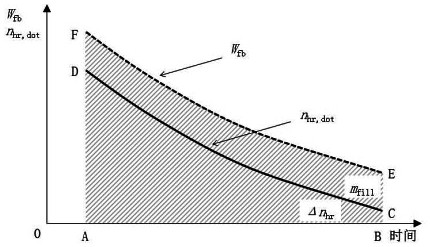

[0022] Step S100, using the fuel filling amount m fill and the increase in the conversion speed of the high-pressure rotor during the filling process Δn hr Get High Pressure Rotor Acceleration n hr,dot fill rate with start-up phase W fb The corresponding relationship, calculate the filling rate W fb ;

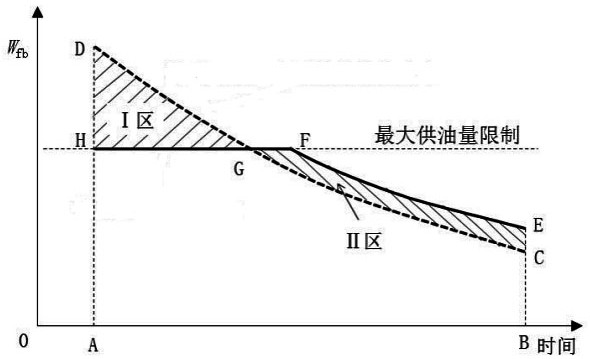

[0023] In order to be able to run at a giv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com