Nanoscale flexible electronic transfer printing method driven by surface tension

A surface tension, nano-level technology, applied in nanotechnology, nanotechnology, nanotechnology and other directions for materials and surface science, can solve the problems of invisible transfer process, unfavorable device precise positioning, device damage, etc. Conducive to precise positioning, large operating space, and simple overall process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the present invention will be further described below in conjunction with technical solutions and accompanying drawings.

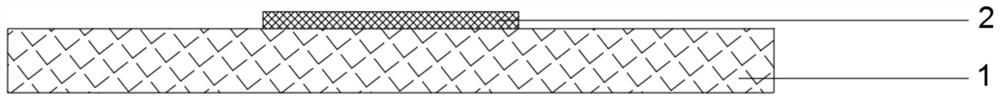

[0031] (1) if figure 1 As shown, the deionized water used to clean electronic devices (a gold film with a thickness of 600 nm with a serpentine structure) was changed to a hydrophilic liquid with viscosity and surface tension. Exemplarily, the liquid used may be, but not limited to, a sodium stearate soap solution with a concentration of 3%;

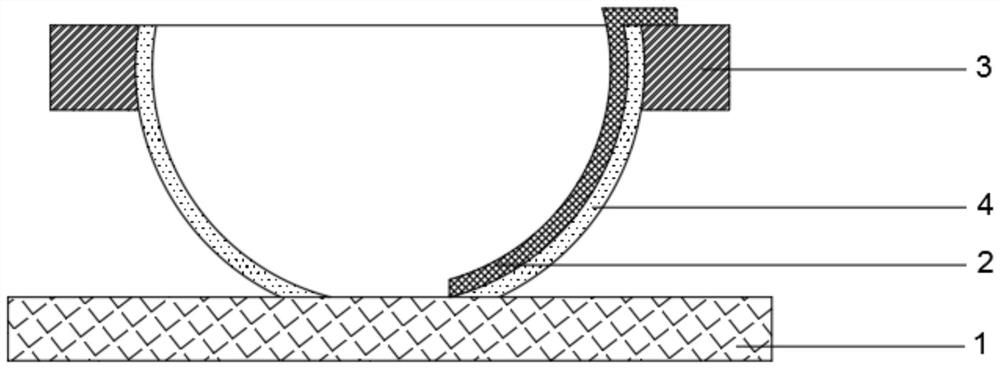

[0032] (2) if figure 2 As shown, a ring with a radius of 5 cm is placed under the electronic device film in the soap solution, a corner of the electronic device film is placed on the ring, and the ring is lifted from the soap solution at a speed of 1 cm per second. During this process, a layer of soap film will be formed between the ring that leaves the liquid surface and the soap liquid surface, and the electronic device film is attached to the soap film and gradually separates from the soap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com