Wound Stators for Rotating Electric Machines

A technology for rotating electrical machines and stators, used in the manufacture of motor generators, electromechanical devices, electrical components, etc., can solve problems such as machine performance decline, machine size increase, increase in conductor quantity, etc., to achieve axial size reduction, weight and production. The effect of cost reduction and avoidance of reduction in motor performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Identical, similar or analogous elements retain the same reference from one figure to another.

[0038] The embodiments described below are in no way restrictive; variants of the invention are especially conceivable that include only a selection of features described below in isolation from other described features, if this selection of features is sufficient relative to The prior art provides a technical advantage or distinguishes the present invention. In particular, all variants and all embodiments described can be combined with one another, if technical aspects do not prevent this combination. In this case, this will be referred to in this specification.

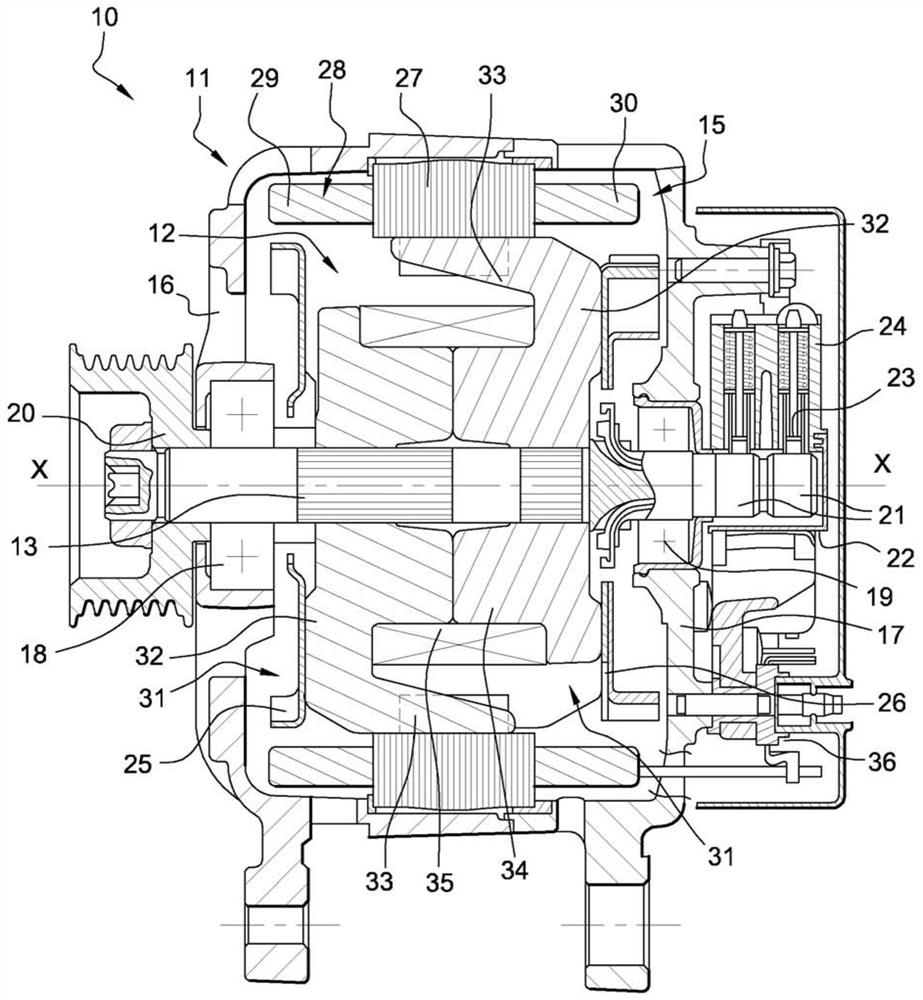

[0039] figure 1 An example of a compact multi-phase rotating electrical machine 10 is shown, in particular for a motor vehicle. The rotating electrical machine 10 converts mechanical energy into electrical energy in an alternator mode, and is operable in a motor mode to convert electrical energy into mechanical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com