Method for separating normal hydrocarbon and isohydrocarbon by using simulated moving bed

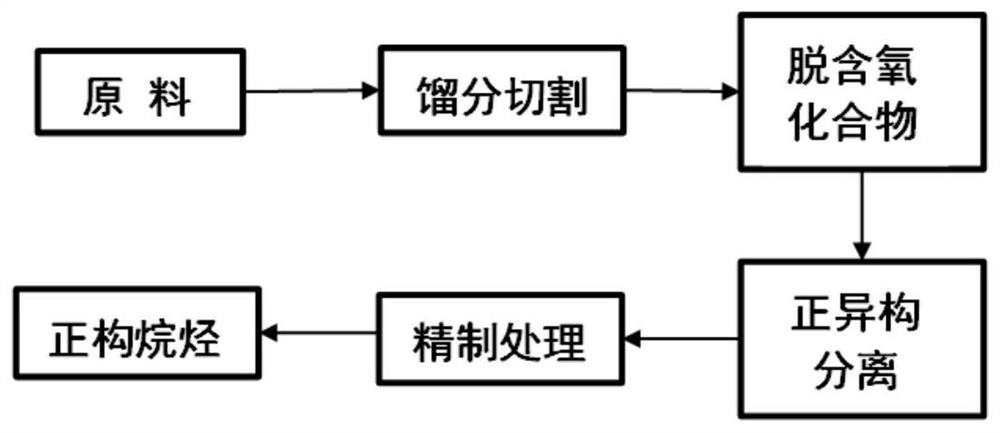

A technology for simulating fluidized beds and normal hydrocarbons, which is applied in the chemical industry, can solve the problems of increased equipment cost, limited adsorption column building height, and high production costs, and achieves reduced equipment investment costs, continuous and effective separation, and a wide range of carbon numbers. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

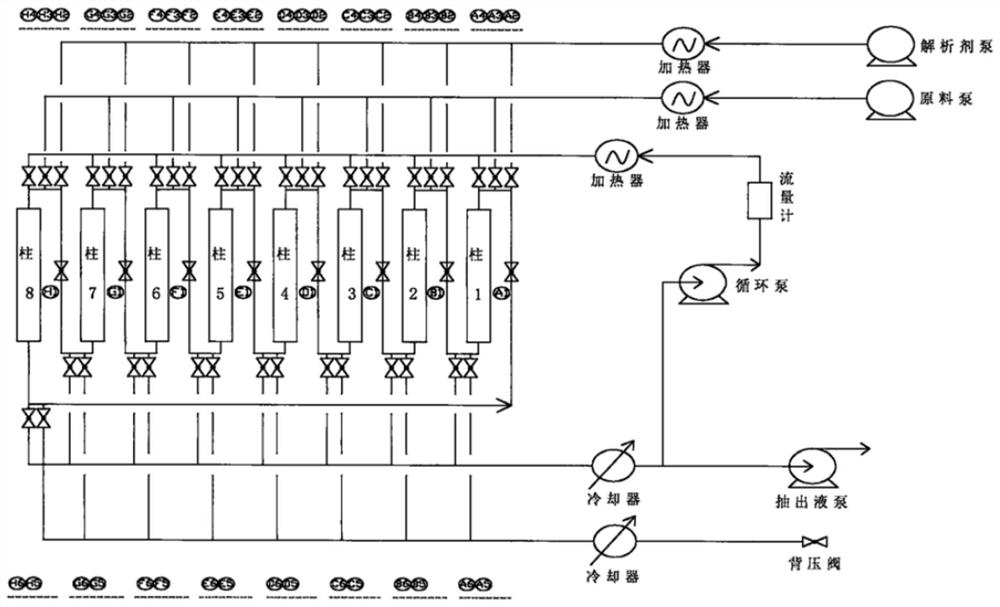

Method used

Image

Examples

Embodiment 1

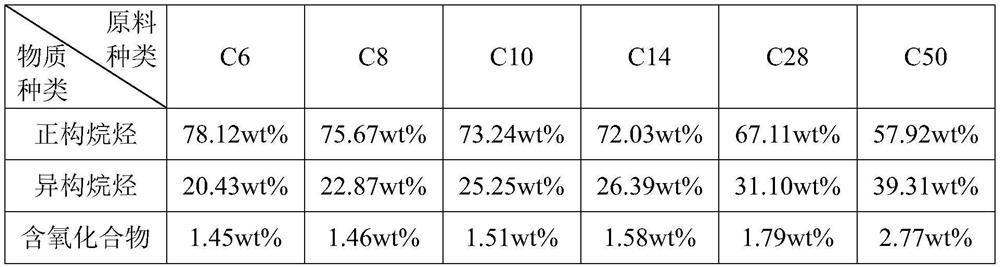

[0080] In this embodiment, the C6 component in Table 2 is used as the raw material (the oxygen-containing organic compound content is less than 1ppm), and the mixture composed of n-octane and isooctane is used as the eluent, and the C8 eluent contains n-octane 70% (w / w) and isooctane 30% (w / w), the eluate is pretreated to remove poisons (oxygen-containing organic compounds, etc.) that are ineffective for adsorption.

[0081] Use a simulated moving bed to process the above C6 components to separate normal paraffins and isoparaffins, the operating temperature is 20°C, the operating pressure is 0.1Mpa, and the molecular sieve is 3A molecular sieve;

[0082] The product obtained in the above steps is passed into the refining tower, and the n-paraffin component with carbon number 6 is separated from the top of the tower, and the eluent component flows out from the bottom of the tower.

Embodiment 2

[0084] In this embodiment, the C8 component in Table 2 is used as the raw material (the oxygen-containing organic compound content is less than 1ppm), and the mixture composed of n-decane and isodecane is used as the eluent, and the C10 eluent contains n-decane 90% (w / w) and isodecane 10% (w / w), the eluate is pretreated to remove poisons (oxygen-containing organic compounds, etc.) that are ineffective for adsorption.

[0085] Use a simulated moving bed to process the above C8 components to separate normal paraffins and isoparaffins. The operating temperature is 40°C, the operating pressure is 0.7Mpa, and the molecular sieve is 10X molecular sieve;

[0086] Pass the product obtained in the above steps into the refining tower, separate the n-paraffin component with 8 carbon numbers from the top of the tower, and the eluent component flows out from the bottom of the tower.

Embodiment 3

[0088] In this embodiment, the C10 component in Table 2 is used as a raw material (the oxygen-containing organic compound content is less than 1ppm), and the mixture composed of n-hexane and isohexane is used as an eluent, and the C6 eluent contains n-hexane 60% ( w / w) and isohexane 40% (w / w), and the eluate is pretreated to remove poisons (oxygen-containing organic compounds, etc.) that are ineffective for adsorption.

[0089] Use a simulated moving bed to process the above C10 components to separate normal paraffins and isoparaffins. The operating temperature is 60°C, the operating pressure is 1.0Mpa, and the molecular sieve is 10X molecular sieve;

[0090] Pass the product obtained in the above steps into the refining tower, separate the n-paraffin component with carbon number 10 from the bottom of the tower, and the eluent component flows out from the top of the tower.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com