A direct spray motor cooling system

A motor cooling and spraying technology, which is applied in the direction of cooling/ventilation devices, electrical components, electromechanical devices, etc., can solve the problems of lower rigidity of the casing and expensive heat pipes, and achieve high insulation, enhanced cooling effect, and volatility small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

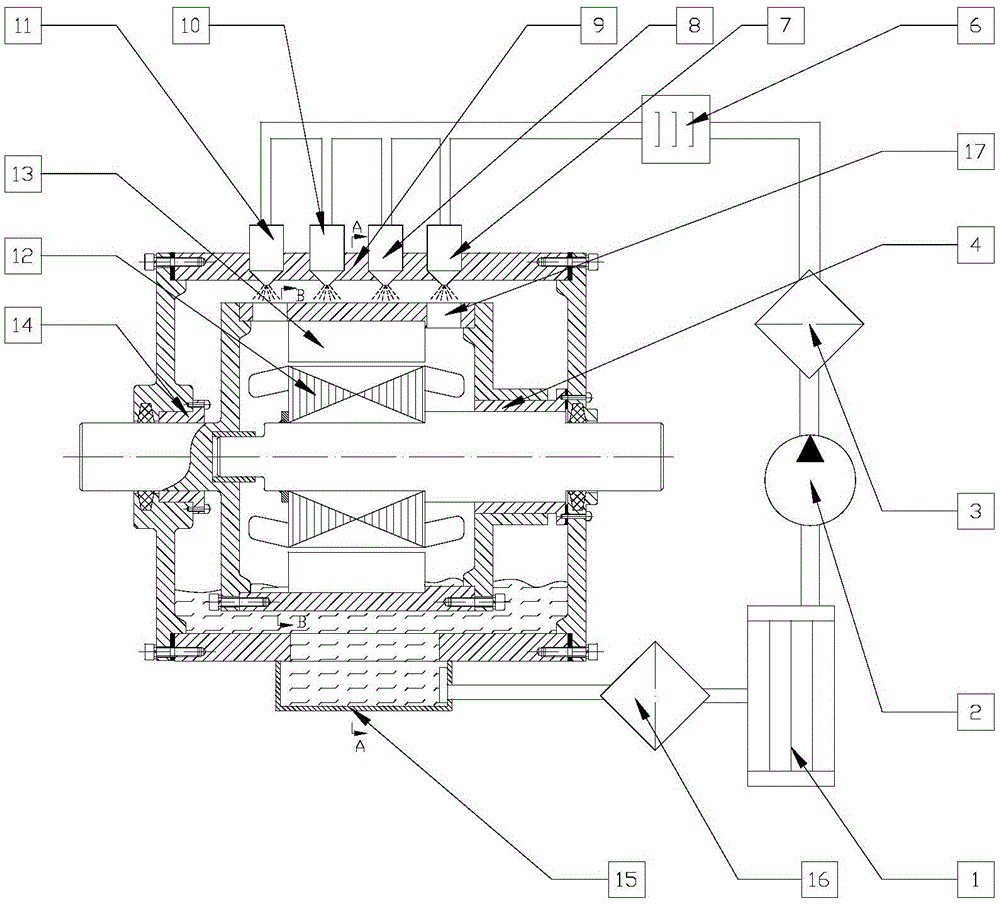

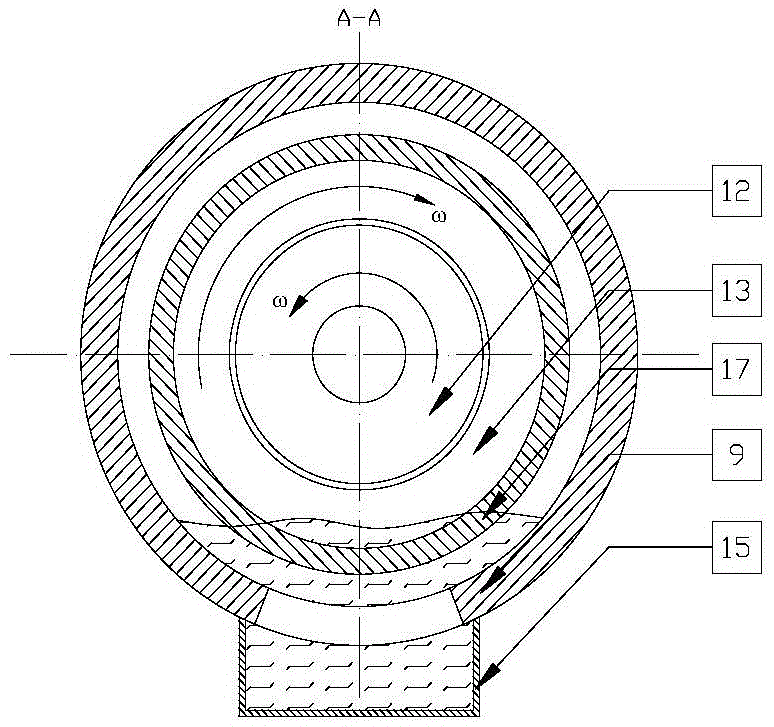

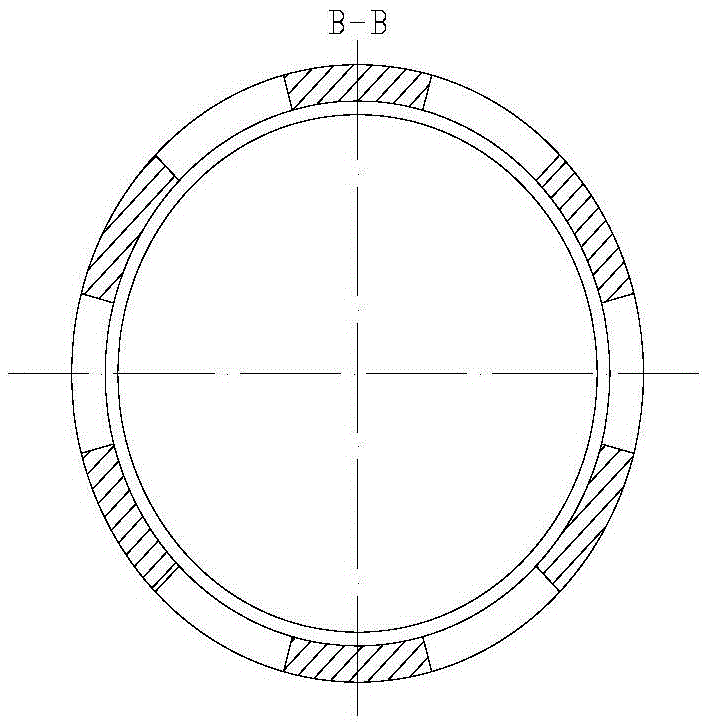

[0027] The counter-rotating double-rotor motor is a new type of electric drive system. It has no stator, and the inner and outer rotors rotate in different directions and output power to both sides respectively. Because the armature winding is rotating and has power output on both sides, it is difficult for traditional air-cooled and water-cooled systems to effectively cool the winding. This embodiment can well solve this problem.

[0028] Such as Figure 1-3 As shown, a direct spray motor cooling system is applied to the cooling of counter-rotating dual-rotor motors. The direct spray motor cooling system includes a radiator 1, an oil pump 2, a fine filter 3, a dryer 6, a nozzle, an oil pan 15, and a coarse filter 16; there are multiple nozzles, namely the first nozzle 7 and the second nozzle 8. The third nozzle 10 and the fourth nozzle 11; the radiator 1, the oil pump 2, the fine filter 3 and the dryer 6 are connected in sequence through pipelines, and the dryer 6 is connec...

Embodiment 2

[0035] The motor in this embodiment has an outer stator and inner rotor structure, and the composition of the direct spray motor cooling system in this embodiment is basically the same as that in Embodiment 1.

[0036] Figure 4 , Figure 5 Shown is another embodiment of the invention. Such as Figure 4 , 5As shown, a direct spray motor cooling system is applied to motor cooling with an outer stator inner rotor structure. The direct spray motor cooling system includes a radiator 1, an oil pump 2, a fine filter 3, a dryer 6, a nozzle, an oil pan 15, and a coarse filter 16; there are multiple nozzles, namely the first nozzle 7 and the second nozzle 8. The third nozzle 10 and the fourth nozzle 11; the radiator 1, the oil pump 2, the fine filter 3 and the dryer 6 are connected sequentially through pipelines, and the dryer 6 is connected with multiple nozzles through pipelines; The oil pan 15 is connected to the coarse filter 16 , and the coarse filter 16 is connected to the r...

Embodiment 3

[0039] The motor in this embodiment has an outer rotor and inner stator structure, and the composition of the direct spray motor cooling system in this embodiment is basically the same as that in Embodiment 1.

[0040] Figure 6 , Figure 7 Shown is a third embodiment of the invention. Such as Figure 6 , 7 As shown, a direct spray motor cooling system is applied to motor cooling with an outer rotor inner stator structure. The direct spray motor cooling system includes a radiator 1, an oil pump 2, a fine filter 3, a dryer 6, a nozzle, an oil pan 15, and a coarse filter 16; there are multiple nozzles, namely the first nozzle 7 and the second nozzle 8. The third nozzle 10 and the fourth nozzle 11; the radiator 1, the oil pump 2, the fine filter 3 and the dryer 6 are connected sequentially through pipelines, and the dryer 6 is connected with multiple nozzles through pipelines; The oil pan 15 is connected to the coarse filter 16 , and the coarse filter 16 is connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com