Preparation method and preparation equipment of shell powder artistic coating material capable of removing formaldehyde

An art paint and formaldehyde removal technology, applied in the field of art paint, can solve the problems of paint containing more formaldehyde, no formaldehyde, and great harm, and achieve the effects of avoiding harm to the human body, preventing cracks, and prolonging life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

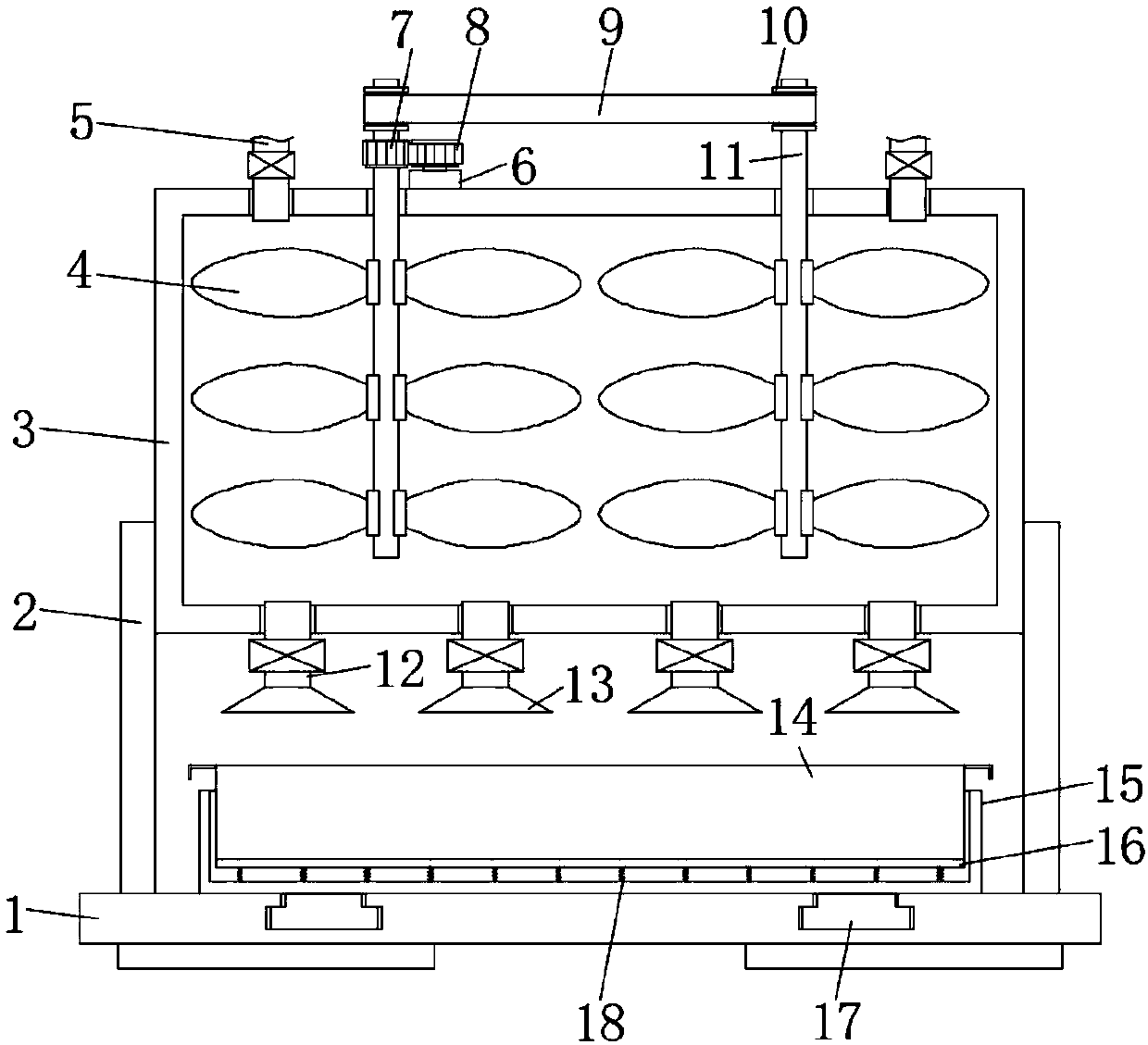

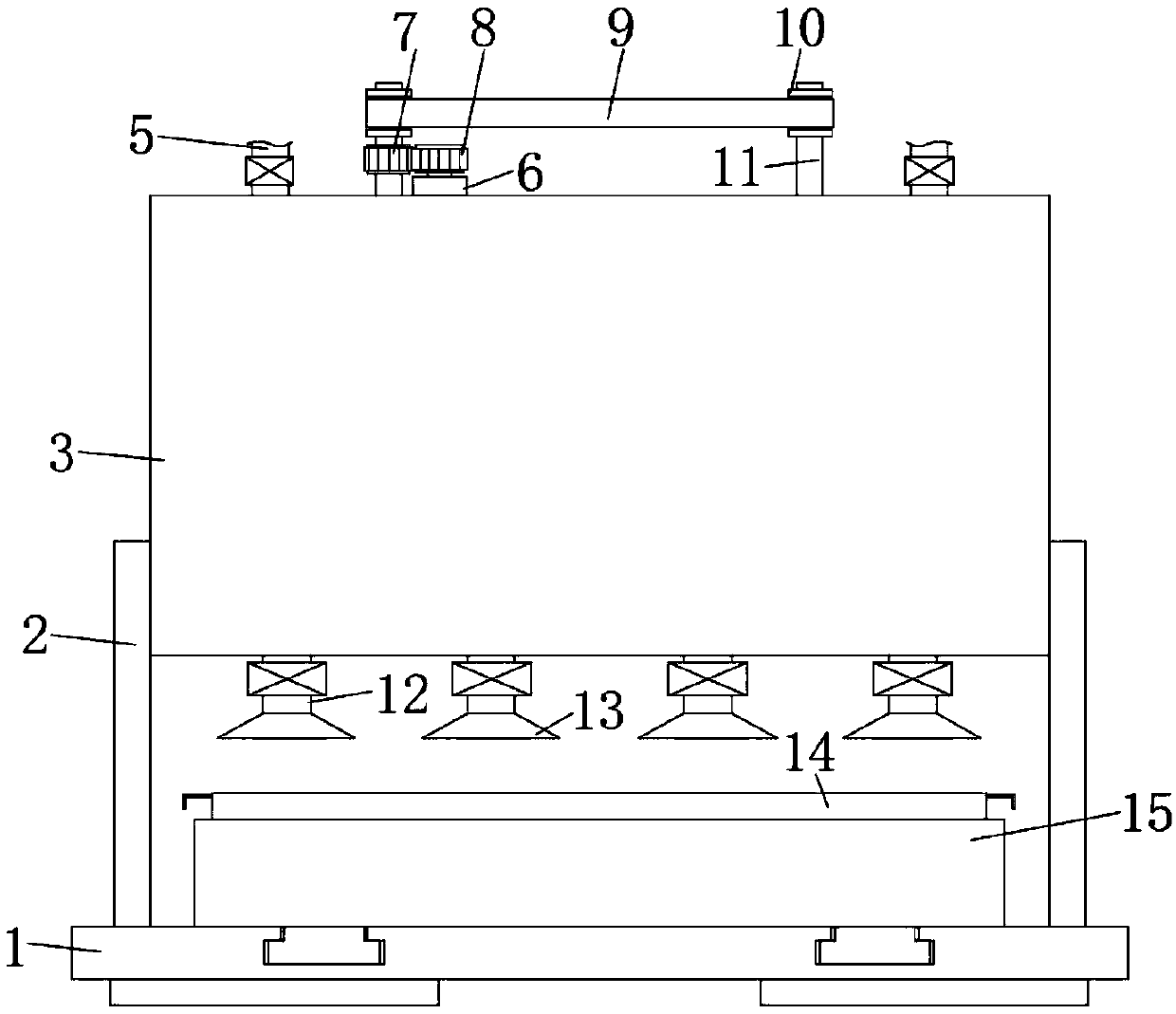

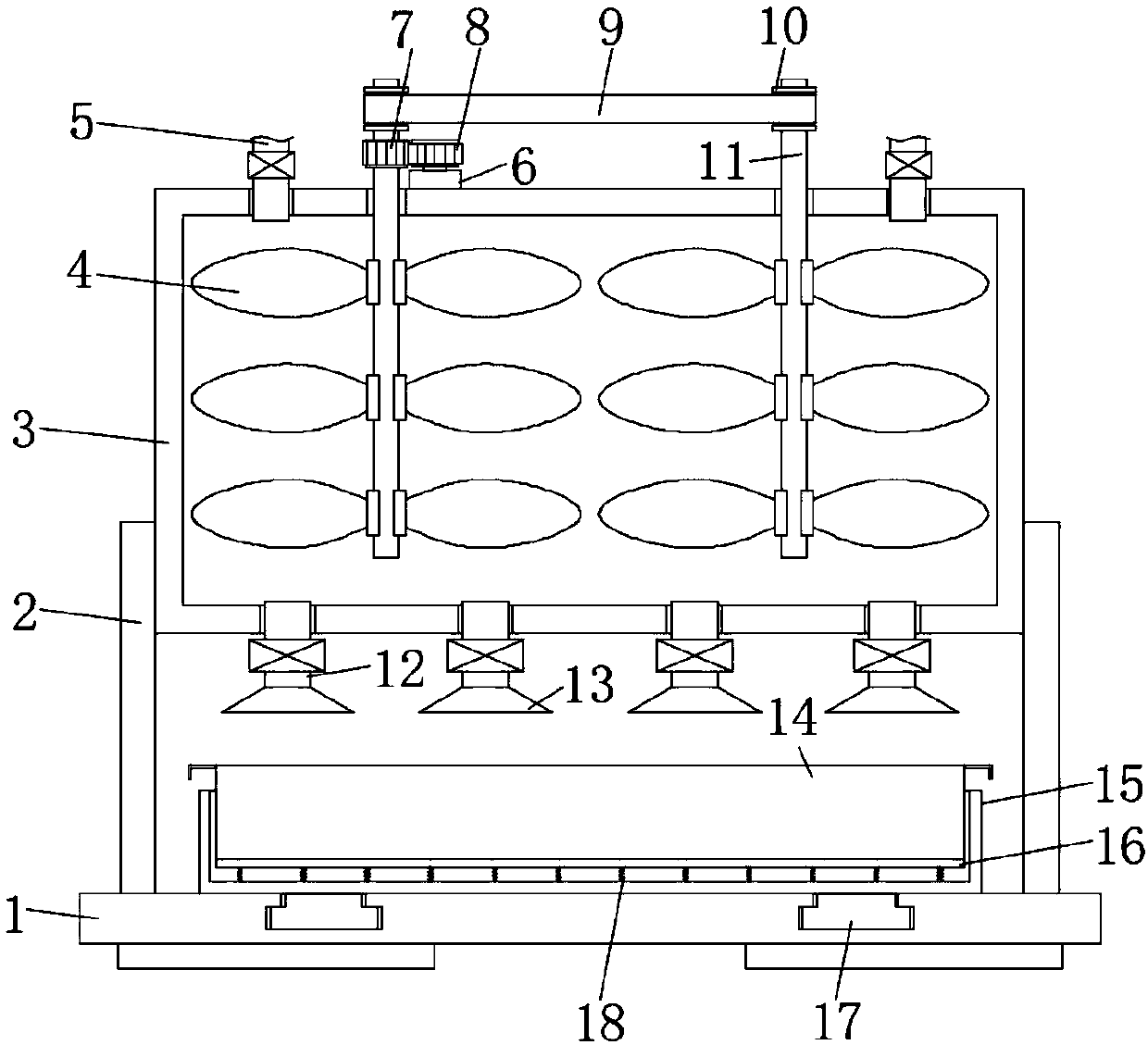

Image

Examples

Embodiment 1

[0029] A preparation method of shell powder art paint capable of removing formaldehyde, comprising the following steps:

[0030] S1, prepare the following raw materials in parts by weight: 200 parts of water, 20 parts of soluble propylene glycol copolymer, 5 parts of soluble dispersant, 2 parts of soluble defoamer, 0.5 part of soluble preservative, 0.5 part of soluble wetting agent, 100 parts of shell powder , 40 parts of soluble vegetable gum, 150 parts of soluble titanium dioxide, 2 parts of soluble ethanol copolymer, 5 parts of soluble sodium octadecanoate copolymer, 2 parts of soluble alkaloid copolymer, 0.5 part of soluble cellulose copolymer, soluble dye 20 parts of water reducing agent, 1 part of soluble water reducer, 0.5 part of soluble thickener;

[0031] S2, the shell powder is screened through the sieve, which can realize the removal of impurities contained in the shell powder, and can also realize the screening and removal of the shell powder with larger particles...

Embodiment 2

[0035] A preparation method of shell powder art paint capable of removing formaldehyde, comprising the following steps:

[0036] S1, prepare the following raw materials in parts by weight: 300 parts of water, 25 parts of soluble propylene glycol copolymer, 8 parts of soluble dispersant, 4 parts of soluble defoamer, 1.5 parts of soluble preservative, 1.5 parts of soluble wetting agent, 200 parts of shell powder , 60 parts of soluble vegetable gum, 200 parts of soluble titanium dioxide, 3 parts of soluble ethanol copolymer, 15 parts of soluble sodium octadecanoate copolymer, 3.5 parts of soluble alkaloid copolymer, 2 parts of soluble cellulose copolymer, soluble dye 30 parts of water reducing agent, 3 parts of soluble water reducer, 1.5 parts of soluble thickener;

[0037] S2, the shell powder is screened through the sieve, which can realize the removal of impurities contained in the shell powder, and can also realize the screening and removal of the shell powder with larger par...

Embodiment 3

[0041] A preparation method of shell powder art paint capable of removing formaldehyde, comprising the following steps:

[0042] S1, prepare the following raw materials in parts by weight: 400 parts of water, 30 parts of soluble propylene glycol copolymer, 10 parts of soluble dispersant, 5 parts of soluble defoamer, 2 parts of soluble preservative, 2 parts of soluble wetting agent, 250 parts of shell powder , 80 parts of soluble vegetable gum, 250 parts of soluble titanium dioxide, 4 parts of soluble ethanol copolymer, 25 parts of soluble sodium octadecanoate copolymer, 5 parts of soluble alkaloid copolymer, 3 parts of soluble cellulose copolymer, soluble dye 40 parts of water reducing agent, 4 parts of soluble water reducer, 2 parts of soluble thickener;

[0043] S2, the shell powder is screened through the sieve, which can realize the removal of impurities contained in the shell powder, and can also realize the screening and removal of the shell powder with larger particles ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com