Critical air treatment device for preparing electronic product corrosive liquid

A technology for air treatment devices and electronic products, applied in air heaters, lighting and heating equipment, steam/steam condensers, etc., can solve problems such as inability to use corrosive liquids for electronic products, temperature and humidity rise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

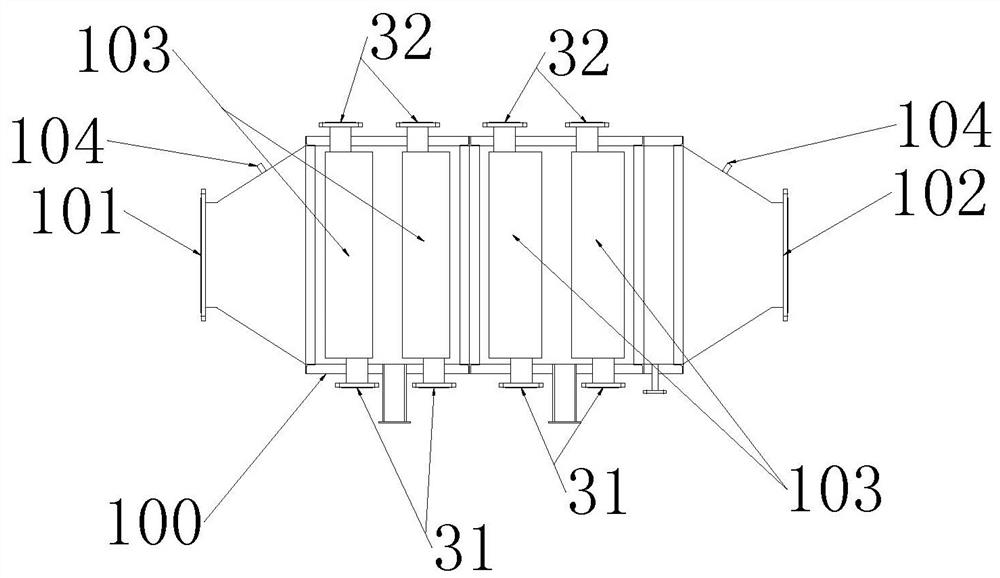

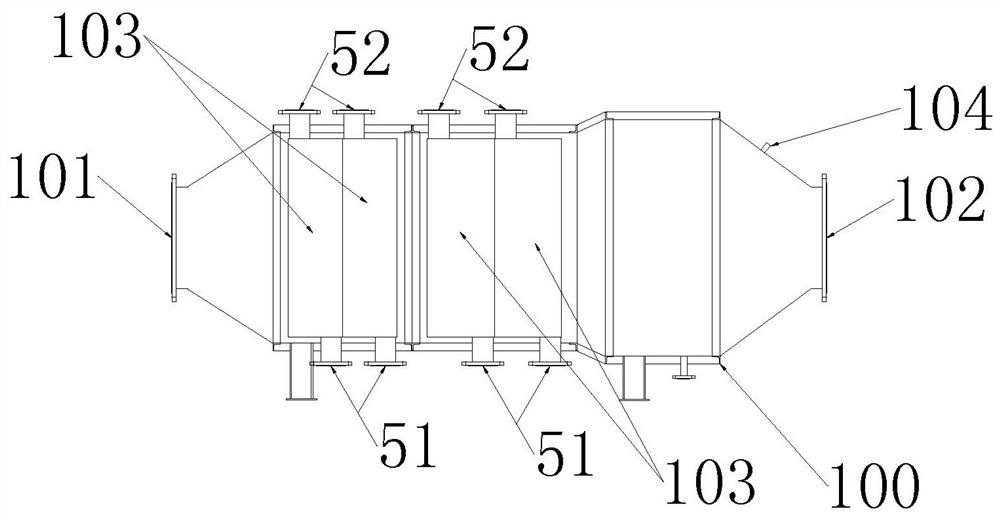

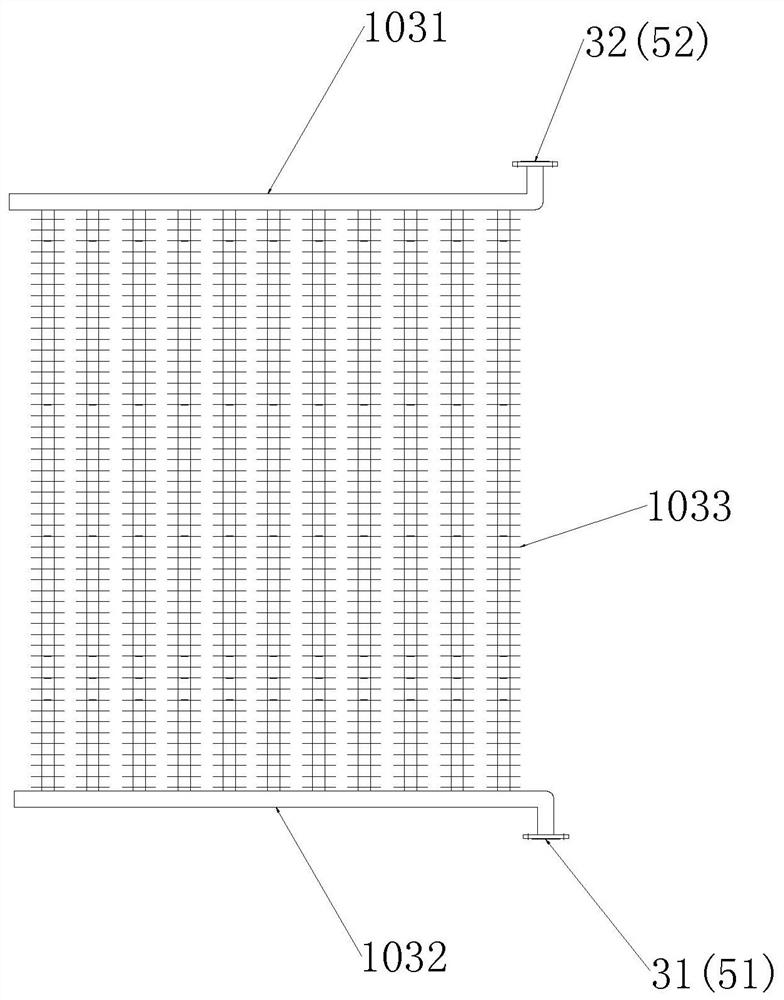

[0023] Such as figure 1 The shown critical air treatment device for the preparation of corrosive liquid for electronic products includes a high-pressure blower 1, the air inlet of the high-pressure blower 1 is connected with a primary filter 2, and the air outlet of the high-pressure blower 1 is connected with a first-stage air cooler in turn 3. Water separator one 4, secondary air cooler 5, water separator two 6, air heater 7 and high efficiency filter 8, combined figure 2 , 3 As shown, the primary air cooler 3 is provided with a circulating water inlet 31 and a circulating water outlet 32, and the secondary air cooler 5 is provided with a frozen water inlet 51 and a frozen water outlet 52, and the frozen water inlet 51 and the frozen water outlet 52 are respectively connected to The outlet and the inlet of the chiller 9 are connected for recycling, and the air heater 7 is provided with a steam inlet 71 .

[0024] Specifically, the above-mentioned devices can respectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com