Growth device and method for growing wide-plate bismuth germanate crystals by descending method

A growth device, bismuth germanate technology, which is applied in the field of preparation of wide plate-shaped bismuth germanate crystals, can solve the problems of difficulty and size disadvantages of bismuth germanate crystals, and achieve the effect of avoiding crucible corrosion and shortening the cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

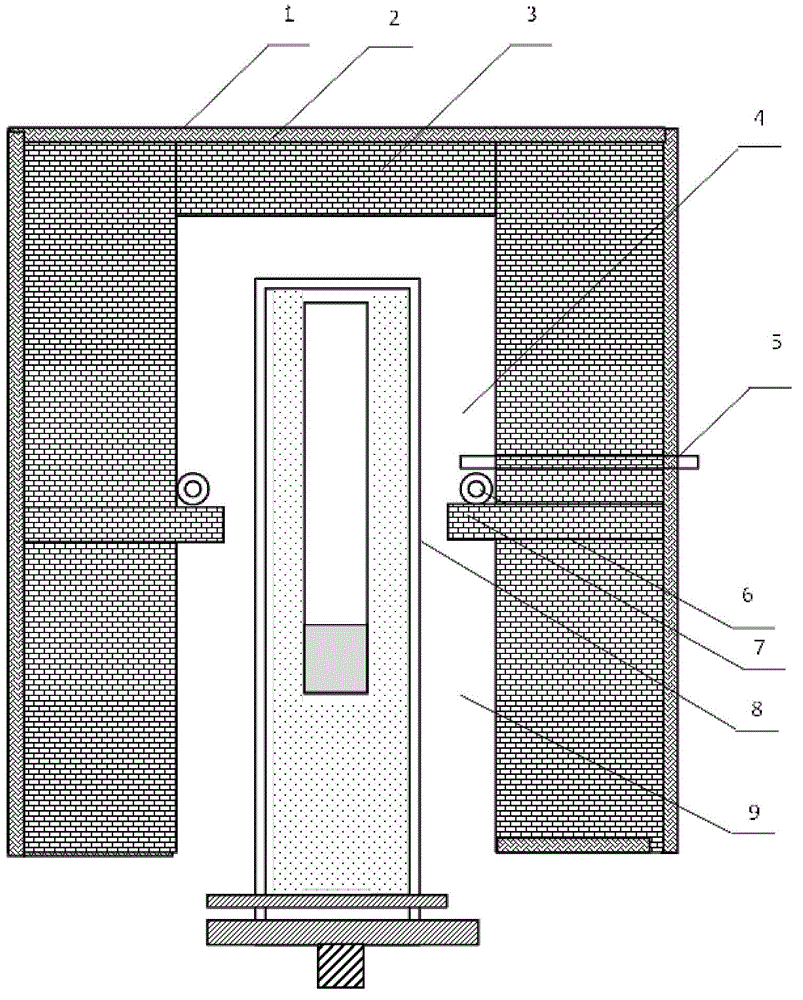

[0055] Wide plate shape 600×30×350mm 3 The preparation of bismuth germanate crystal, concrete preparation method is as follows:

[0056] Bismuth trioxide and germanium dioxide with a purity of 4N or more are weighed and mixed according to the stoichiometric ratio of 2:3, and then placed in a platinum crucible to heat up to above the melting point temperature and kept warm to completely melt the raw materials, and quickly injected into the mold, cooling to obtain more Crystal ingot.

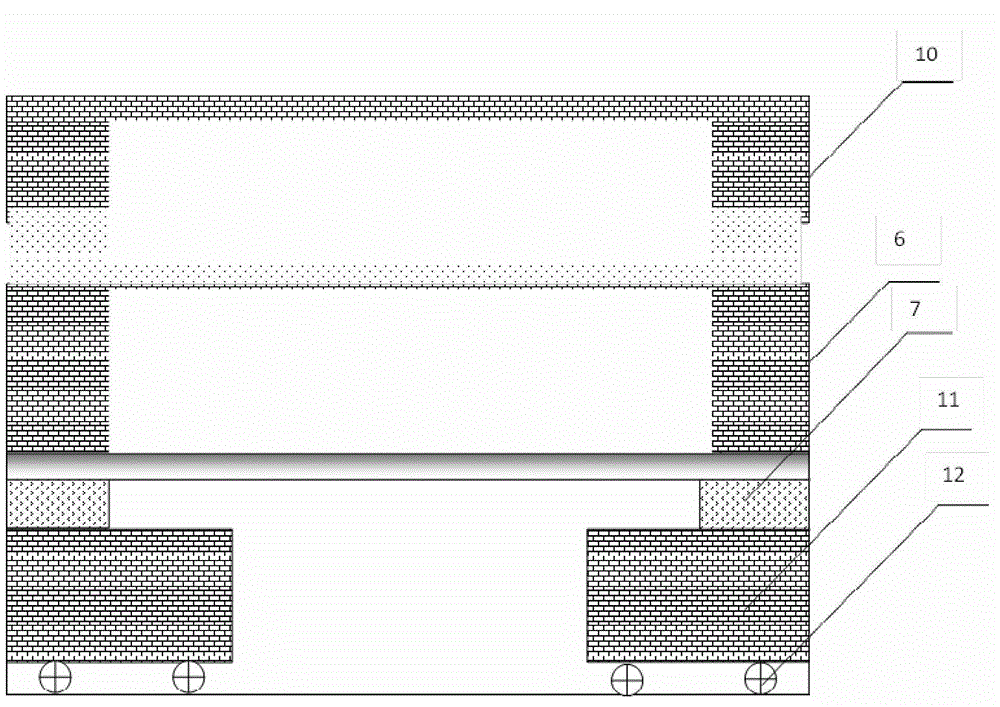

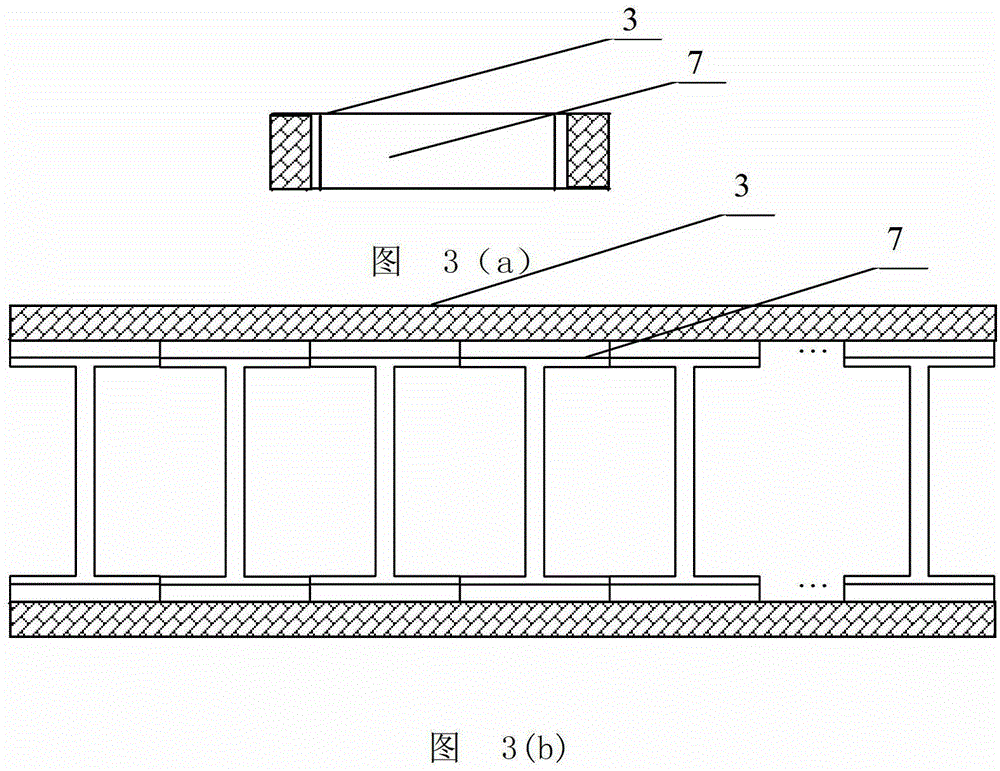

[0057] A 3-layer platinum sheet with a thickness of 0.16mm is made into a section of 600×30mm 2 , a cuboid crucible with a height of 400mm.

[0058] Select the section as 680×94mm 2 , Thickness is 8mm, length is 360mm rectangular parallelepiped aluminum oxide lower crucible.

[0059] Select the size as 600×30×30mm 3 Bismuth germanate crystals were cut, ground and cleaned as seeds, and the length (600mm) of the seed crystals was consistent with the width (600mm) of the wide plate crystals.

...

Embodiment 2

[0063] Wide plate shape 600×30×350mm 3 The preparation of bismuth germanate crystal, concrete preparation method is as follows:

[0064] The ready-made bismuth germanate crystal is selected, cut and ground into the required size and shape, and cleaned as the crystal block of the growth raw material.

[0065] Other steps of embodiment 2 are as described in embodiment 1, and finally make described wide plate bismuth germanate crystal (such as Figure 6 ).

Embodiment 3

[0067] Wide plate shape 600×30×350mm 3 The preparation of bismuth germanate crystal, concrete preparation method is as follows:

[0068] Control the vertical drop rate of the alumina downed crucible to be 0.6 mm / hour and the temperature gradient at the crystal growth interface to be 20 Kelvin / centimeter (K / cm).

[0069] Other steps of embodiment 3 are as described in embodiment 1 or 2, finally make described wide plate shape bismuth germanate crystal (such as Figure 6 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com