A preparation method of consumable electrode for electroslag remelting

A consumable electrode and electroslag remelting technology, which is applied in the field of alloy processing, can solve the problems of incomplete combination of small-scale consumable electrodes, restrictions on the development of high-speed steel preparation, alloy ingot segregation and cracks, etc. The problem of easy cracking, avoiding electrode cracking, and eliminating the effect of internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for preparing a consumable electrode for electroslag remelting. The material of the consumable electrode is high-speed steel, and the ingredients are formulated according to the chemical composition and content of the steel. The electric arc furnace and LF / VD refining furnace are used to process the steel. Refining, bottom injection to produce steel ingots, the diameter of the steel ingot (consumable electrode) is 650mm; the steel ingot is demoulded and put into the resistance furnace, first isothermal preheating, the isothermal preheating temperature is 680°C, and kept at this temperature for 10h; Heating slowly at a heating rate of 30°C / h, heating to 890°C and holding at this temperature for 20 hours; then rapidly cooling to 730°C and holding at this temperature for 20 hours; after naturally cooling down to 350°C in the resistance furnace, take out the steel ingot And naturally cooled to room temperature in the air; the test hardness value is HSD32; before use...

Embodiment 2~5

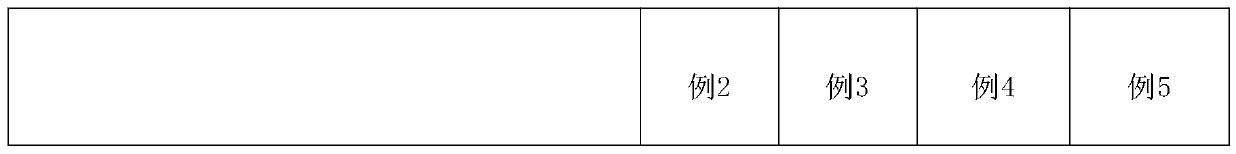

[0028] The preparation methods of Examples 2-5 are similar to those of Example 1, and the differences are shown in Table 1.

[0029] Table 1

[0030]

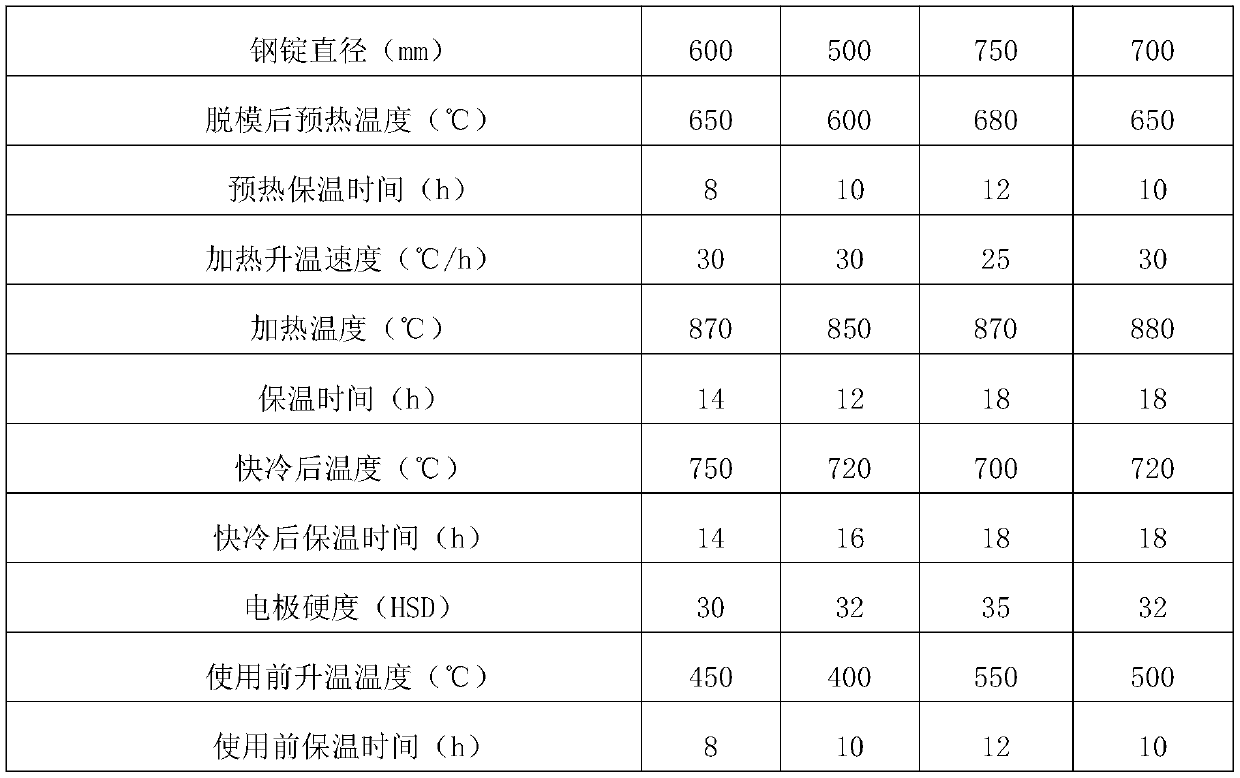

[0031]

[0032] The consumable electrodes prepared in Examples 1 to 5 are used in electroslag remelting production of cold roll steel, which can ensure stable production during the whole remelting process without cracks and block dropping.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com