Double-sided detection method and double-sided detection equipment

A detection method and detection equipment technology, which is applied in semiconductor/solid-state device testing/measurement, measurement devices, optical testing defects/defects, etc., can solve the problem of time-consuming and labor-intensive labor, the inability to ensure the quality of double-sided wafers, and the impact on detection accuracy and detection Quality and other issues, to achieve the effect of shortening the time interval, improving detection efficiency, and improving continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

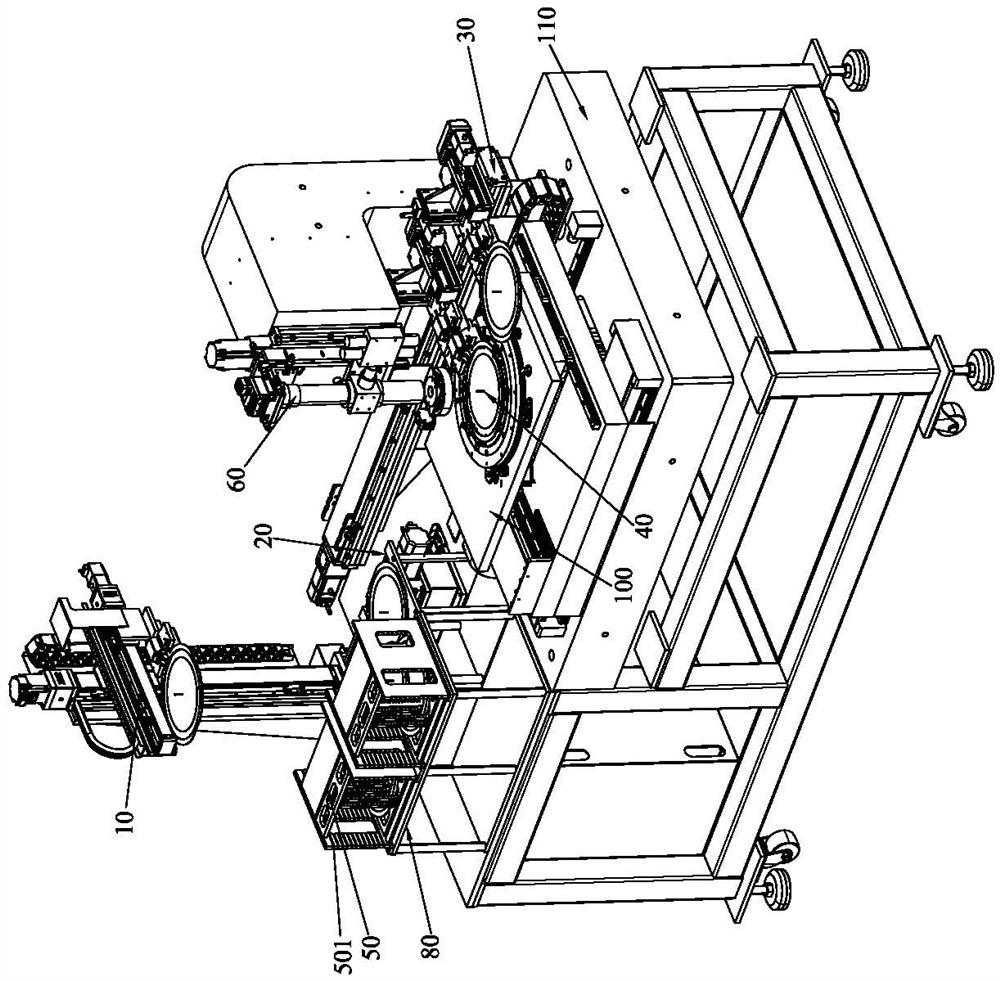

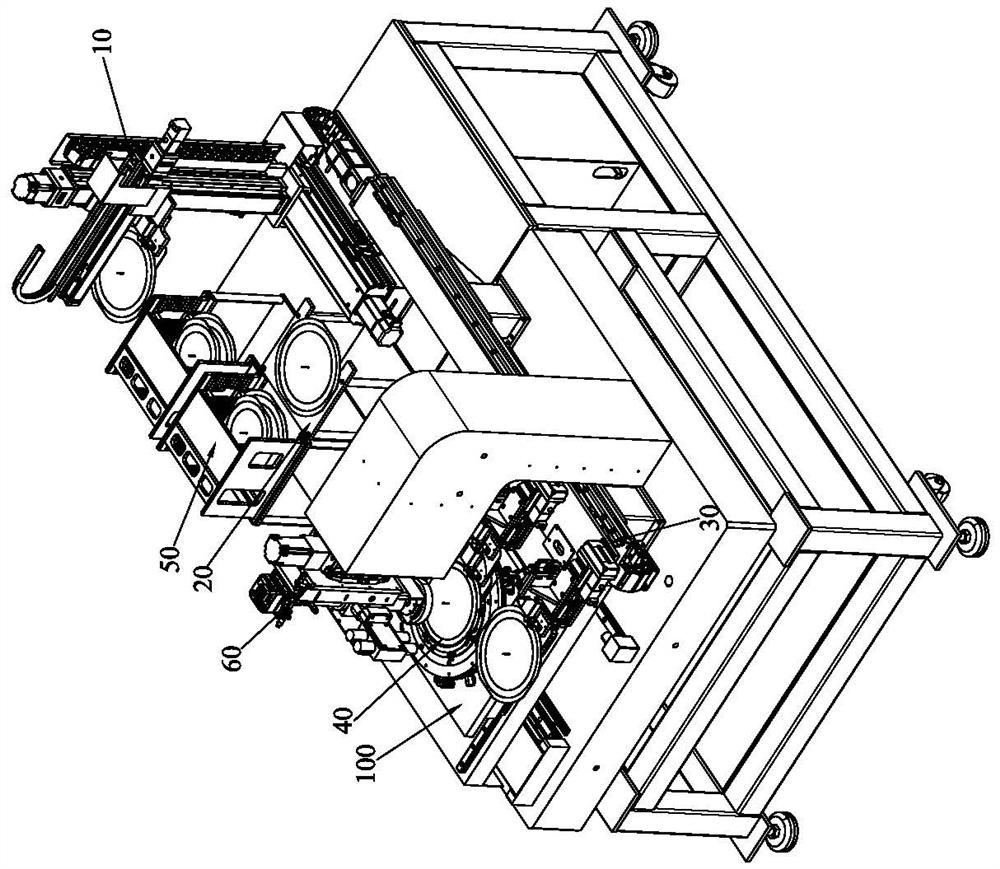

[0059] Please refer to Figure 1 to Figure 10 As shown, it shows the specific structure of a preferred embodiment of the present invention, including a double-sided detection method, including the following steps:

[0060] Step 1: After the pick-and-place mechanism 10 puts a product to be tested in the tray for indexing 20, the pick-and-place device A31 in the duplex displacement planting mechanism 30 moves to the tray for indexing 20 to grab a product to be inspected. Product, at this time, the pick-and-place device B32 in the duplex displacement planting mechanism 30 is in an idle state, wherein the pick-and-place device A31 and the pick-and-place device B32 are arranged in sequence;

[0061] Step 2: the pick-and-place device A31 puts a product to be detected to the double-sided detection station 40 for detection, at this time, the pick-and-place device A31 and the pick-and-place device B32 are both in an idle state;

[0062] Step 3: The pick-and-place device B32 moves to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com