Copper smelting sludge resourceful treatment device

A processing device and resource-based technology, applied in chemical instruments and methods, filtration separation, fixed filter element filters, etc., can solve the problems of filter blockage, inconvenient cleaning of sludge, etc., and achieve the effect of preventing blockage and facilitating cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

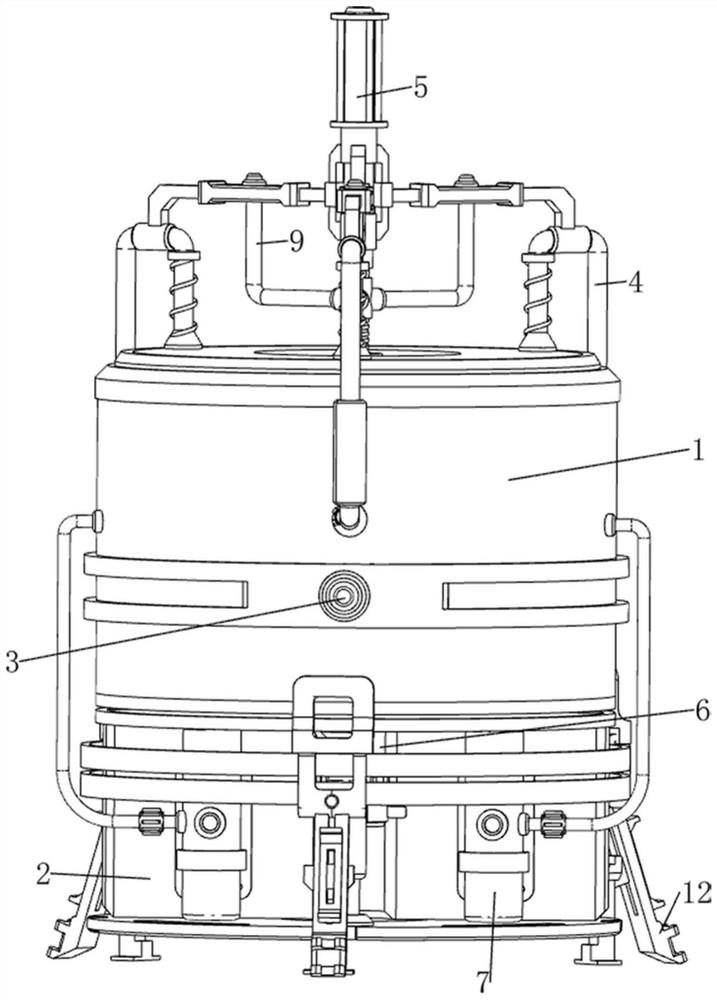

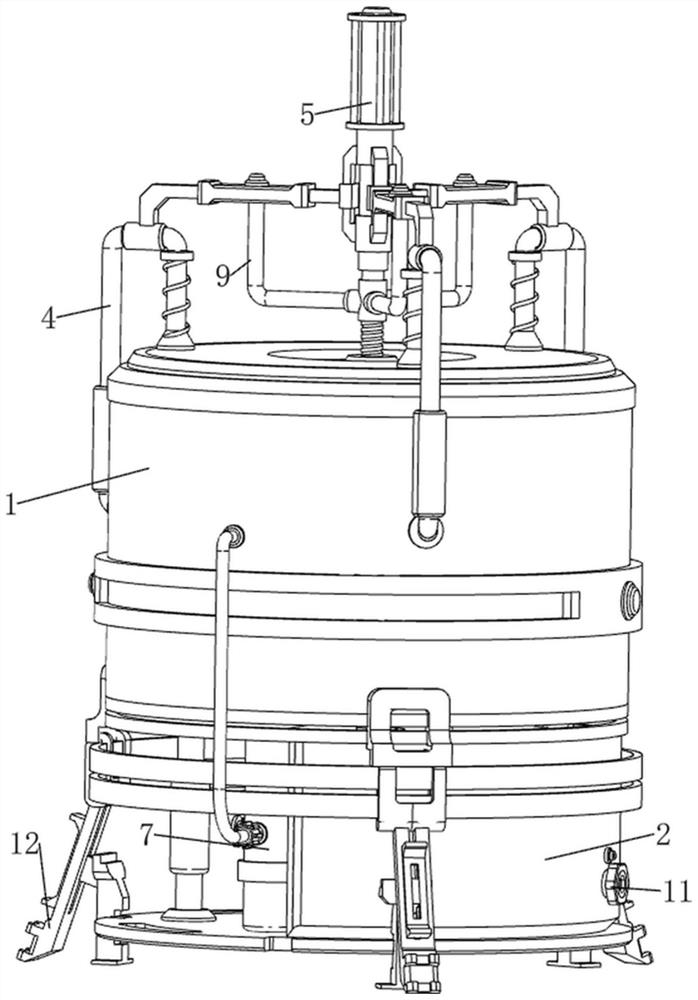

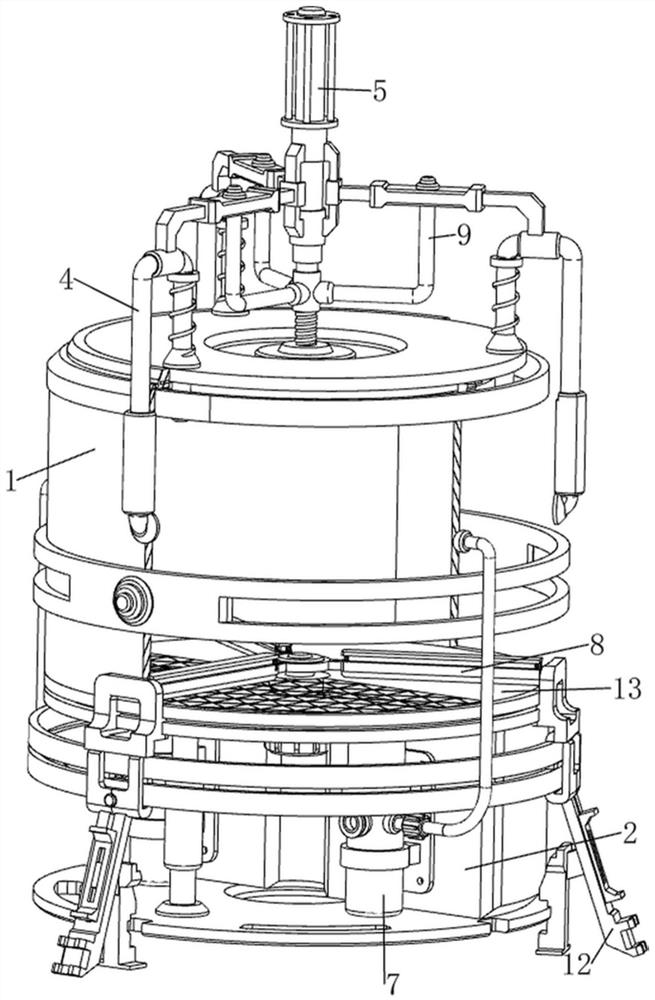

[0041] A copper smelting sludge recycling treatment device, such as Figure 1-Figure 10 As shown, it includes a first discharging frame 1, a first electromagnetic valve 11, a support 12, a screen 13, a second discharging frame 2, a feeding mechanism 4, a crushing mechanism 5, a discharging mechanism 6 and a mixing mechanism 7 , the upper part of the support 12 is welded with the first discharge frame 1, the lower part of the support 12 is provided with the second discharge frame 2, the upper part of the support 12 is rotatably provided with a screen 13, and the screen 13 is composed of a semicircle entity and a semicircle mesh screen Circular structure, the screen 13 is located on the lower side of the first discharge frame 1, and the second discharge frame 2 is provided with a first solenoid valve 11 on the lower rear side. After the first solenoid valve 11 is opened, the second discharge frame can be The waste water in 2 is discharged outwards. The upper part of the first di...

Embodiment 2

[0048] On the basis of Example 1, such as figure 2 , image 3 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 with Figure 16 As shown, anti-clogging mechanism 8 is also included, and anti-clogging mechanism 8 includes blocking rod 81, movable plate 82 and second spring 83, and three blocking rods 81 are welded at even intervals on the upper side of rotating shaft 64, and the upper part of blocking rod 81 is all sliding Be provided with movable plate 82, movable plate 82 and retaining rod 81 when rotating, can scrape off the waste residue on the screen cloth 13, prevent screen cloth 13 from causing clogging, all set between movable plate 82 and the retaining rod 81 tops of same side. There are four second springs 83 .

[0049] When the lower pressing plate 54 moved downward, the lower pressing plate 54 would contact the movable plate 82, and the lower pressing plate 54 would extrude the movable plate 82 to move downward, and the second spring 83 would ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com