Large-diameter thin-wall elbow forming method

A forming method and large-diameter technology, applied in forming tools, metal processing equipment, manufacturing tools, etc., can solve problems such as elbow scrapping, deformation and cracking of folds, and fold expansion, so as to improve the yield rate, ensure the quality of finished products, Applicable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings.

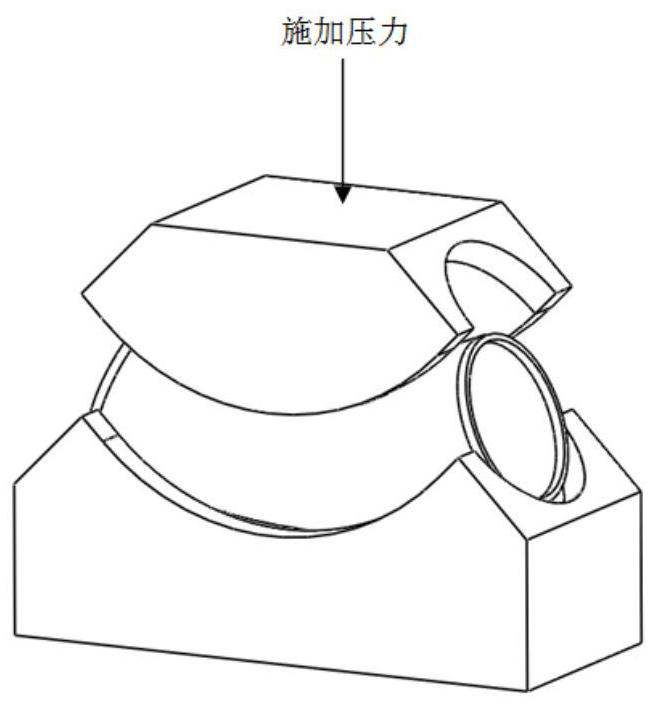

[0017] In this embodiment, taking a 90° elbow as an example, the seamless pipe is first bent into a 3D elbow, and then the 3D elbow is pressed into a 1.5D elbow by using a combination of bending forming process and pressing forming process.

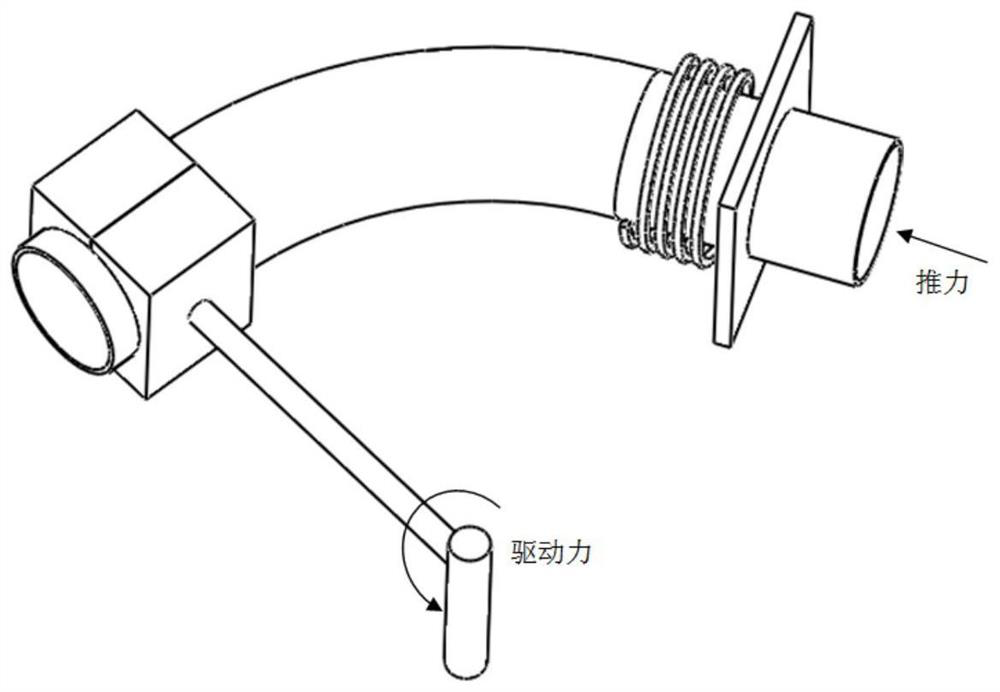

[0018] Specifically, such as figure 1 As shown, the induction coil is placed on the part of the tube blank (thin-walled seamless tube) to be bent, and the tube head is fixed with a mechanical arm. The tube blank is heated by an intermediate frequency current in the induction coil, so that the temperature of the tube blank rises to 900°C , apply a thrust to the rear end of the tube blank, guide the limit block to limit the tube blank, and at the same time, the mechanical arm rotates to make the 3D curved tube bend and form at a speed of 30mm / min. The part of the bent pipe is cooled by spraying water (water pressure 6 kg)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com