Electrical discharge machine

A technology for electric discharge processing machines and processed objects, which is applied in the direction of electric processing equipment, metal processing equipment, circuits, etc., can solve the problems of discharge, unspecified time, etc., and achieve the effect of accurate removal amount and accurate calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention will be described below using the drawings. Various modifications described below can be implemented in any combination.

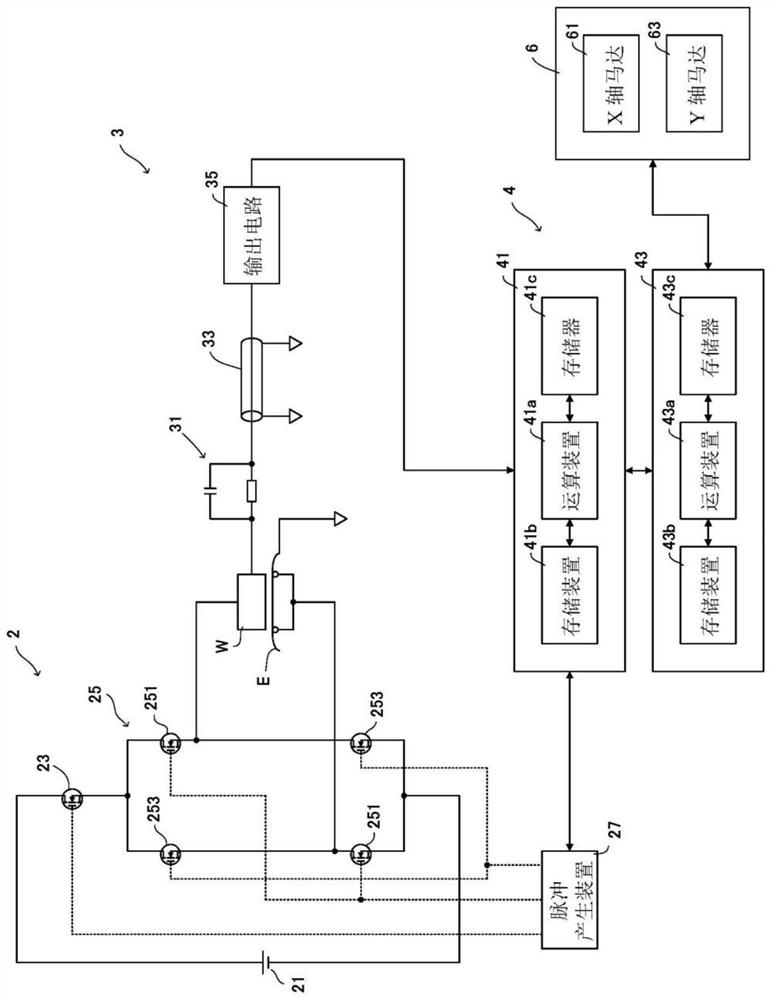

[0026] The electric discharge machine 1 of the present embodiment is a wire electric discharge machine using a wire electrode as the tool electrode E. As shown in FIG. However, the present invention can also be applied to an electrical discharge machining machine using a shaped electrode, a fine-hole electrical discharge machining machine using a rod-shaped electrode or a tubular electrode, and other electrical discharge machining machines.

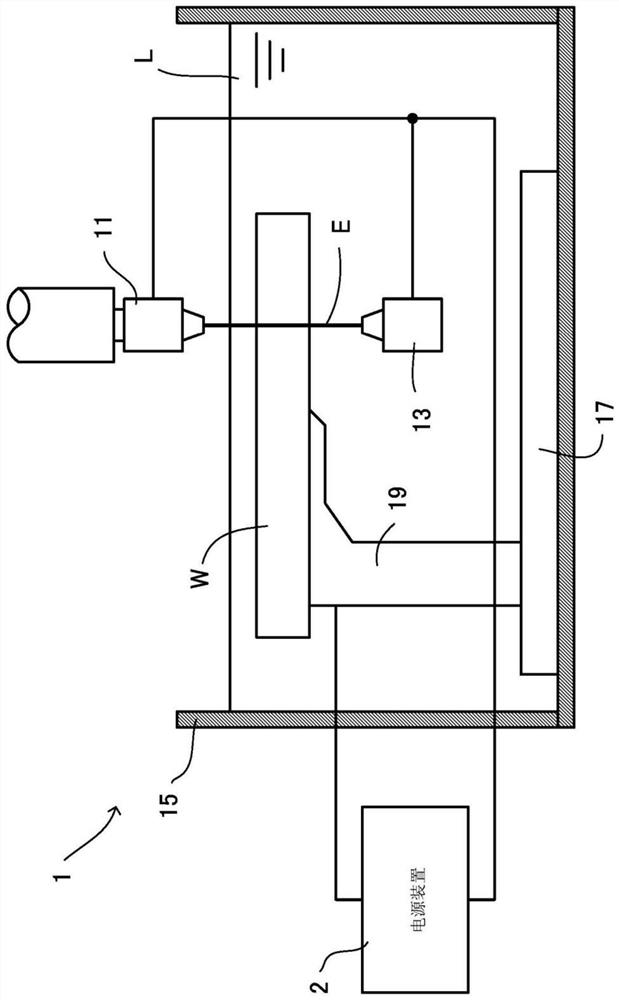

[0027] like figure 1 As shown, the electric discharge machine 1 of this embodiment includes an upper guide assembly 11 , a lower guide assembly 13 , a machining tank 15 , a table 17 , and a workpiece holder 19 . The table 17 is installed in the processing tank 15 , and the workpiece holder 19 is installed upright on the table 17 . The workpiece W to be processed by electr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com