Pneumatic radial tire

A radial tire, tire technology, used in tire parts, tire tread/tread pattern, transportation and packaging, etc. The effect of uniform crown arc growth, good groove crack resistance and good wetland drainage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] A preferred embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

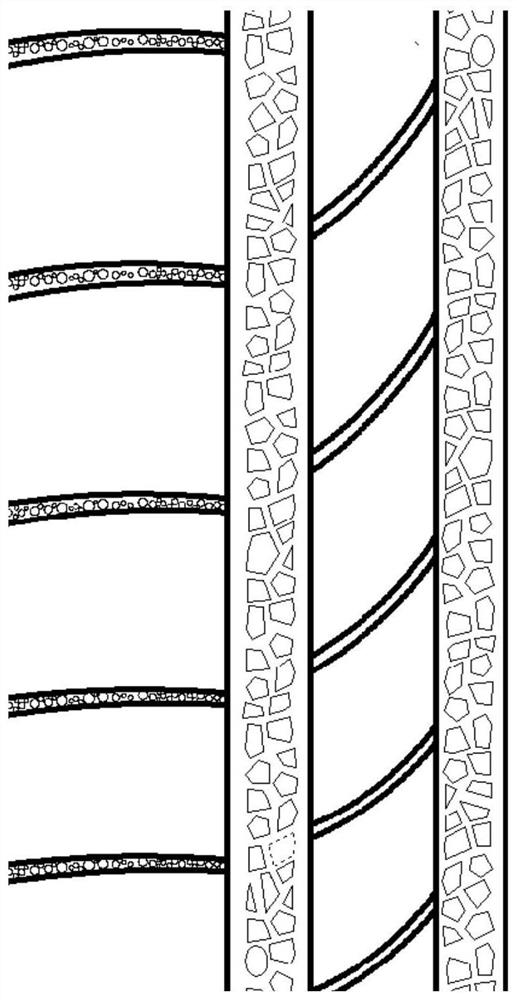

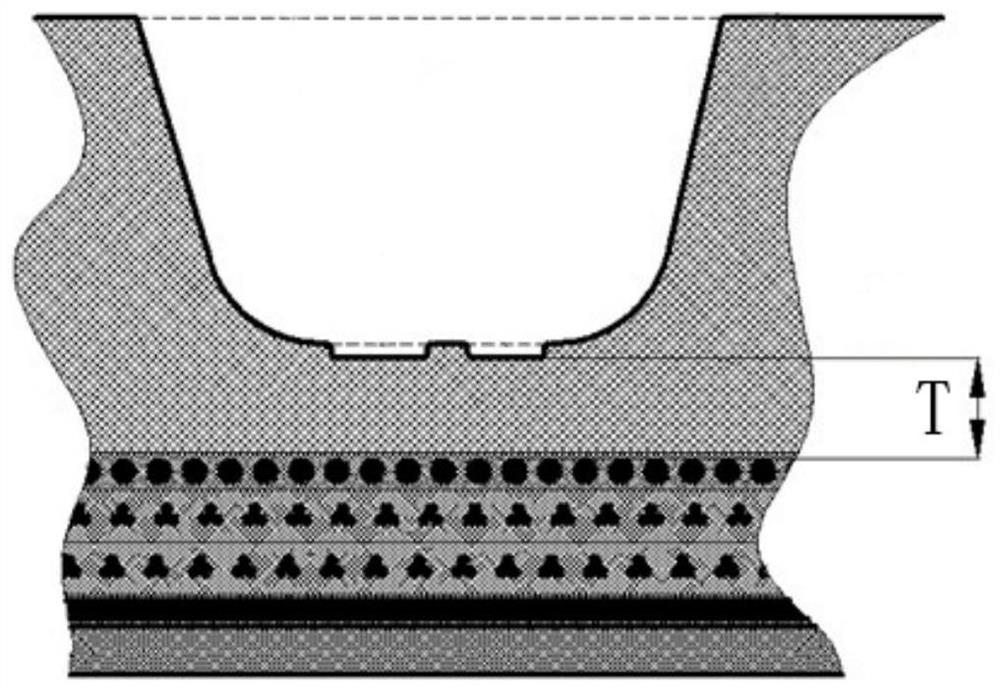

[0016] like figure 1 As shown in the pneumatic radial tire, the crown portion of the carcass profile includes one or more tangent circular arcs and the surface of the crown is provided with at least three longitudinally arranged main grooves and several transverse grooves, the main grooves or transverse grooves The bottom surface of the ditch is provided with a number of pits of unlimited shapes, forming gravel-like lines.

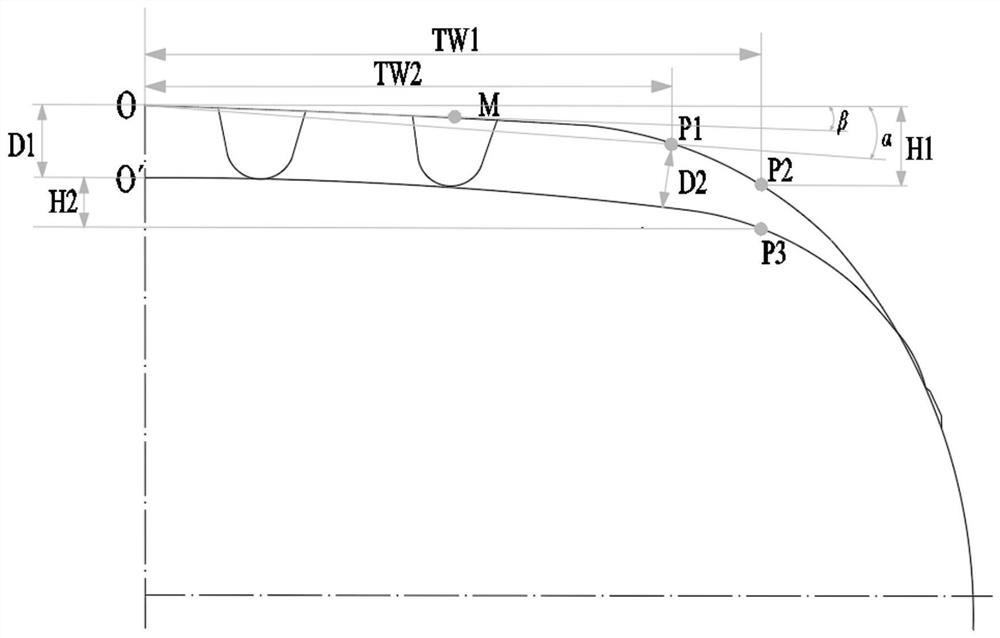

[0017] In order to obtain a tire with more uniform crown arc growth and better anti-grooving performance under the standard inflation air pressure condition of the present invention, the connection line between the center point O and the end point P1 of the crown portion arc described in this preferred embodiment The included angle α≤7° with the horizontal line, the included angle β≤1 / 2α between the line connecting the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com