Sealed storage barrel for glue filling

A sealed storage and filling technology, applied in the direction of sealing, capping with auxiliary devices, sealing parts with opening devices, etc., can solve the problems of glue failure and other problems, and achieve the effect of easy pressing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

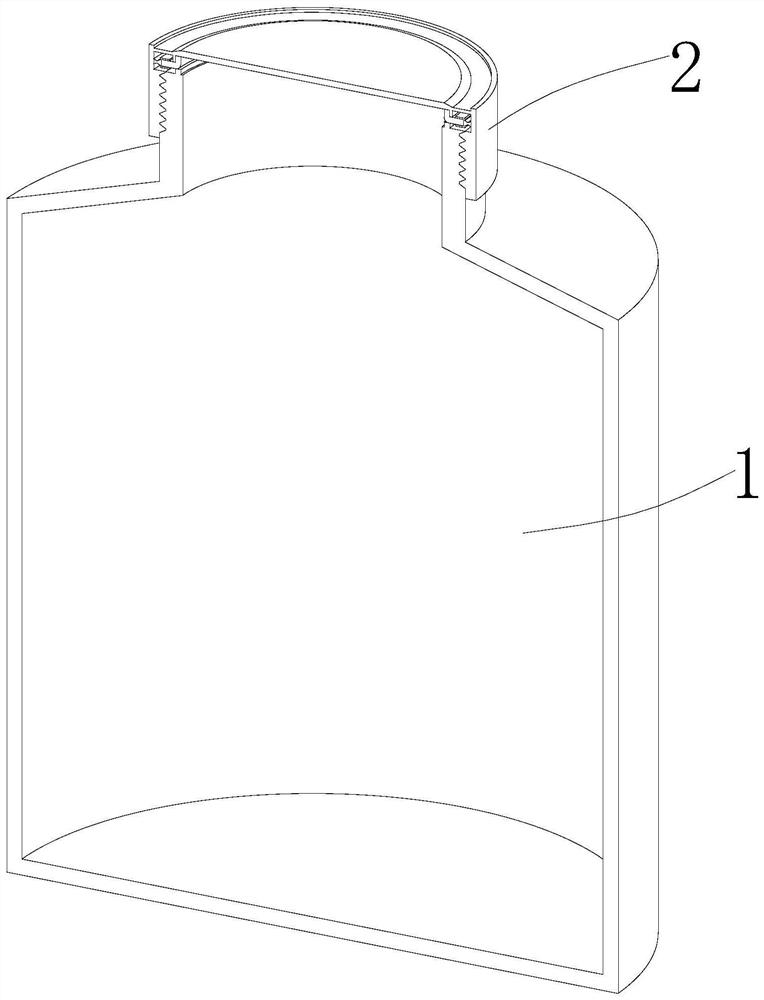

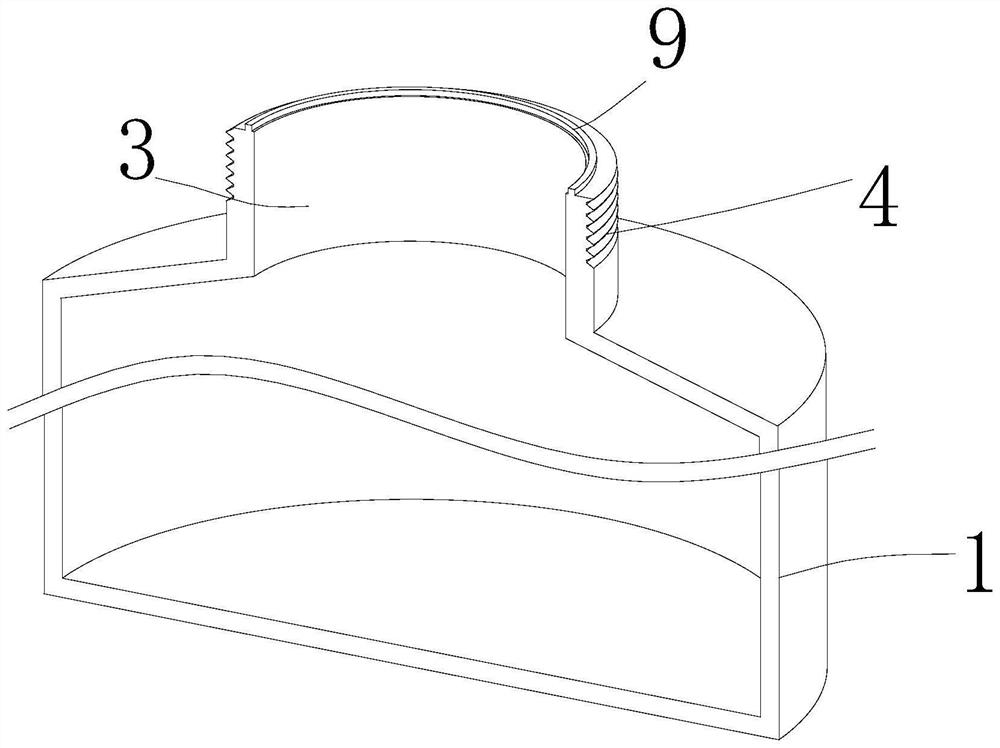

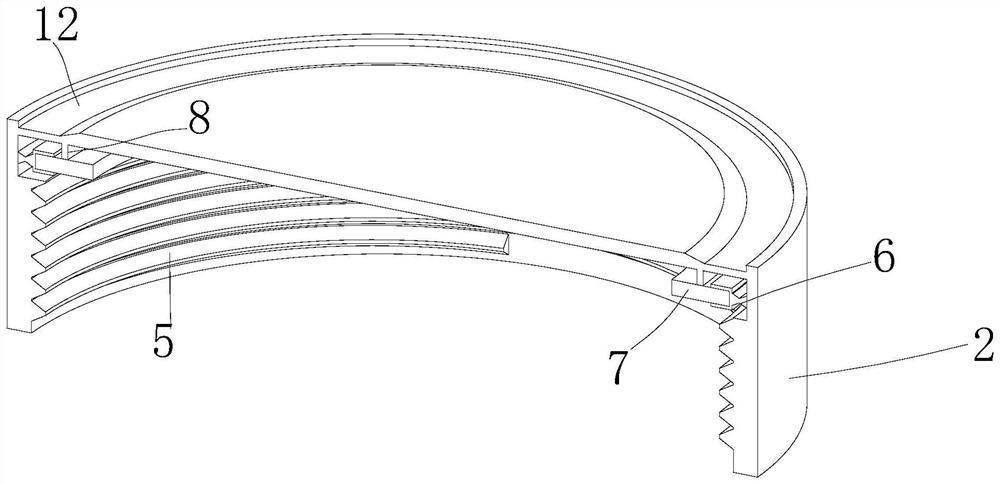

[0022] Embodiment one, such as Figure 1-4 As shown, including the barrel body 1 and the barrel cover 2, the glue is filled inside the barrel body 1, and the top of the barrel body 1 is connected and penetrated with a filling port 3, the filling port 3 is integrated with the barrel body 1, and the filling port 3 The outer surface of the barrel is provided with an external thread groove 4, and the inner side of the bung 2 is provided with an internal thread groove 5, the internal thread groove 5 is located at the bottom of the bung 2, the bung 2 is threadedly connected with the filling port 3, and the inside of the bung 2 The inner side is fixedly installed with a support frame 6 above the internal thread groove 5. The cross-sectional shape of the support frame 6 is "Y" shape, and the upper and lower sides of the connection end of the support frame 6 are provided with grooves 10. Through such settings, better Fixing the sealing sponge 7 and opening the groove 10 can make the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com